Since I was a kid I have been fascinated by motorsport. The incredible speeds make it demanding and thrilling, and winning means only the best will do. Only the best drivers, engineers and support workers break into this elite world. And although it’s about exceptional individuals, I find it fascinating to see how getting to that top spot on the podium means that behind the scenes there’s some seriously superior teamwork going on. Someone is responsible for creating a finely tuned professional sports team that has a shared objective, technical capability, devotion, perseverance and winning mentality to cross that finish line first, repeatedly.

So I have to admit to being more than a little excited when I started working with motorsport companies years ago. Though we can’t usually mention individual companies because of confidentiality agreements, Zuken is well known for working in this area and word of mouth means we are regularly approached by companies working in motorsport who are interested in moving into digital electrical design.

I’d estimate that far more than 50% of teams racing with wheels (including MotoGP) use E3.series for their complete electrical design or relevant areas including many Formula 1 teams.

Of course, this is a huge responsibility with no margin for error

It can be nerve-wracking on a race weekend when we’re following the teams we’ve worked with. There is a great atmosphere in the Milan office on a Monday when things have gone well, and it’s certainly a great motivator to have this passion and focus within our team.

I’m often asked by colleagues what it’s like working in motorsport

I’ll admit that it’s challenging – motorsport customers push us to the limit. They really do keep us ‘race fit’ in our work. Because of the racing calendar, companies have a limited window of opportunity to implement new functionality, upgrade software, or make changes to libraries. This means that when decisions are made, engineering partners like Zuken need to be ready in their own ‘technical pitstops’ with their tools and teams primed for action. We have to be 100% reliable and responsive. My perspective is that it’s good for us to have some adrenaline in our jobs, and it drives us to be the best we can across all areas of our work.

To meet the response times and flexibility demanded by motorsport

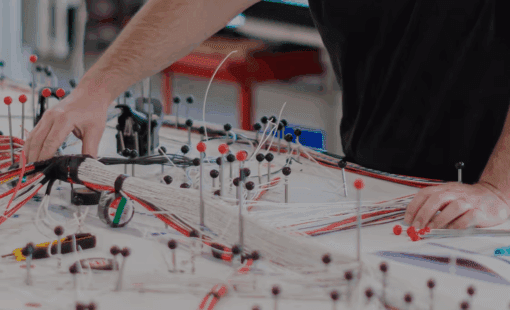

Zuken has recently developed a dedicated E3.series component library for motorsport. This typically means companies can cut they time they spend creating their components by 75%. Like defense, motorsport components are sector-specific.

E3.series takes a unique, object-oriented approach to component creation, so you can find graphics, tables, and metadata all within a single component. Instead of simply being a symbol, E3.series components are purchasable parts. In practice, this means a component can flag the connector it needs to mate to – avoiding mating errors. The library contains comprehensive information for all relevant component data: connectors, backshells, terminals and terminal seals.

Here’s an example of the punishing timescales found in motorsport

One well-known prestigious motorsport brand went from our first site visit to their first completed design using E3.series in 10 weeks. It went like this: 2 weeks to make a purchase decision; 4 weeks to build a custom parts library (this was before we had launched our custom library); and 4 weeks for electrical design. That’s speedy!

Motorsport use the right-the-first-time approach as default

Like the aerospace and space sectors everything is checked and rechecked, so that once the car gets on that track everything works as intended – no compromises. Of course, there might be a mechanical failure because of the harsh operating conditions, but it always works perfectly beforehand.

There’s a positive knock-on effect from working in motorsport that spills over into our work in other sectors

We often hear from prospective customers going through the electrical tool selection process that knowing about our work in motorsport gives them confidence during what can be a stressful time. They recognize that if we can compete and deliver solutions for the elite world of motorsport, we can meet their needs too.

Find out more about E3.series

-

HURRY! There’s still chance to rub shoulders with the engineers behind some of the most successful F1 teams, and the Zuken team supporting them, at Zuken’s global innovation conference.

Related Content

- Seiten

- Products

E3.series ermöglicht einen effizienten und präzisen Gestaltungs- und Fertigungsprozess für die Elektroplanung und Fluidplanung, die Kabelplanung sowie den Kabelbaum- und Schaltschrankaufbau.

- Presse-Information

- Presse-Information