Visiting customers and viewing the results of a product deployment project is always an interesting experience. While as a vendor it is tempting to focus on the unique and visionary functionality of our tools, it is good to be reminded of the very different success perspectives of the senior managers and expert software users who use them every day. I was recently reminded of this insight during a visit to KRONE, one of Europe’s foremost producers of agricultural machinery, based in the rural town of Spelle in Northern Germany.

Supporting the product development process

More often than not, our customers are less interested in the core functionality of the software than the goals and objectives they need to achieve when using it. These are usually product development projects with deadlines, cost and performance targets, alongside project management and coordination efforts. So, success for our customers is only achieved if the tools are deployed in a way that supports the company’s product development process and its related requirements.

Impeccable harnesses

The interview started off with a tour through the KRONE’s ultra-modern manufacturing facilities, where workers are led through each assembly task by 3D digital instructions. I was then expecting to be presented with a high-level vision of the company’s sophisticated innovation process, and its requirements for the electrical engineering tools employed in its wire harness design process that would signify a successful project implementation.

While an impressive gallery of innovation awards testifies that KRONE has a sophisticated innovation process in place, in deploying Zuken’s E3.series the first sign of success came down to something much more down-to-earth. It was, in fact, the company’s senior management pointing out (unprompted) the impeccable execution of the wire harness on the first pre-series vehicle of a new product line that showed the deployment team had got it right.

Since the cable harness takes a long time to source, the engineering team used to have to build in ‘safety margins’ into their harness designs that they concealed in the pre-series products by applying the odd extra loop during the assembly process. This time, no masking was necessary since it was a perfect fit!

ECAD, MCAD and ERP integration

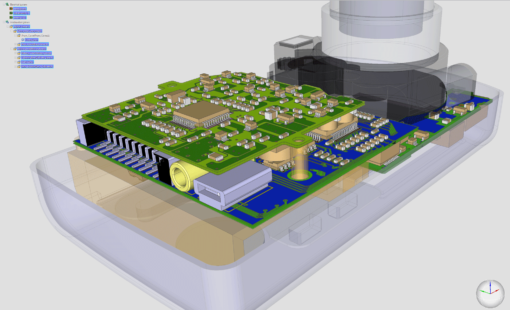

The positive comments for the wiring on KRONE’s new BiG X 480 forage harvester – a 480 HP monster, crammed with the latest technology – proved the success of a process re-engineering initiative initiated by KRONE’s electrical engineering team. Their objective was to integrate electrical engineering, using E³.series, into an interdisciplinary electromechanical product development process. Or, in other words, ECAD, MCAD and ERP integration.

The result: right-first-time execution of the wire harness in the first pre-series vehicle; streamlined collaboration with the wire harness supplier, with substantial cost savings enabled by the provision of fully specified and validated manufacturing information; and an unexpected pat on the back from senior management.

Read the full story in English or German

Find out more about E3.series

Related Content

- Products

Elektrischen und mechanischen Konstruktionen konvergieren mit wenig Spielraum für Fehler. Die Visualisierung von Baugruppen in 3D wird immer wichtiger.

- Products

E3.series ermöglicht einen effizienten und präzisen Gestaltungs- und Fertigungsprozess für die Elektroplanung und Fluidplanung, die Kabelplanung sowie den Kabelbaum- und Schaltschrankaufbau.

- Anwenderbericht