You may have heard about Zuken’s recent acquisition of a Model-Based Systems Engineering (MBSE) company called Vitech Corporation. Yes, Vitech has an MBSE product called GENESYS, but first and foremost, they are a Systems Engineering company. Let’s take a look at Zuken’s leap into digital engineering and MBSE to understand the WHY.

Digital transformation

Many companies have recently embarked on the “digital transformation” journey to become more efficient and more competitive. A recent IDC study* showed that 90% of small and medium-sized businesses are budgeting for the digital transformation, and 73% have begun the process. According to the survey, the top goal for these companies making the digital transformation journey is to improve product development and design processes. Let me repeat that – “the top goal for these companies making the digital transformation journey is to improve product development and design processes”. If the top goal of the digital transformation is to improve product development, Zuken needs to be on that train.

But that is a big train. The part of that train that focuses on product development and is relevant to Zuken is called digital engineering. And that is where the Vitech acquisition story begins.

Digital engineering is disruptive

Zuken sees digital engineering as disruptive when it comes to product development. But what is Digital Engineering?. In 2018, the Department of Defense (DoD) published a digital engineering strategy† as the basis for future DoD programs. The first goal of the strategy is the adoption of a model-based design process that provides a single source of truth. The DoD is taking the lead in defining digital engineering, but the model-based design practice is pervasive. Any complex product development effort can benefit from digital engineering.

The model-based design begins with systems engineering and MBSE tools which align with Vitech’s core competencies. Zuken offers “detailed design” tools for PCB and wire harness subsystems. What if Zuken front-ended their detailed design solutions with a model-based systems engineering solution?. That would put Zuken in the digital engineering solution space. Zuken would not only be in the digital engineering space but would be the only electrical/electronic (E/E) design solution company to offer a model-based design chain.

Model-based design has a process gap

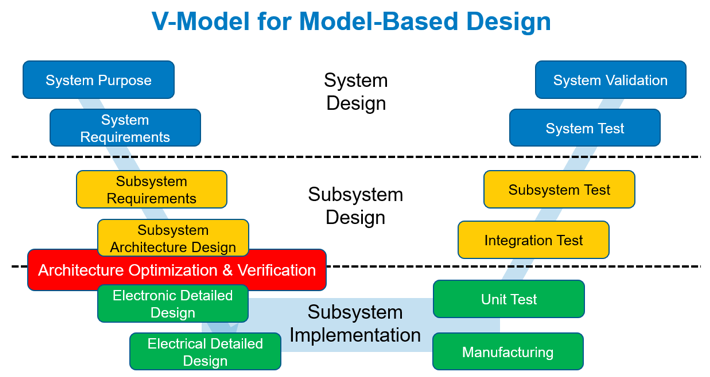

The model-based design has a bit of a problem today. Model realization requires the model to move from systems engineering to detailed design and that is the rub. For E/E subsystems, the model will contain architecture and requirements. The architecture will consist of electronic subsystems (e.g., ECUs or ECMs) and the logical interconnection (e.g., wire harnesses). ECU requirements might include weight, power consumption, dimensions, and functions. The logical interconnect might include signals or wires. Combining the architecture, requirements and functions provide the design team with a design “envelope” that they must accommodate.

But, moving the model architecture and requirements to detailed design is a manual process today. It bypasses the all-important architecture optimization and verification phase, which involves systems engineering and the design team. Companies can spend weeks moving the model into the detailed design tools with a high probability of injecting errors, or even worse, the architecture can’t be implemented within the system model requirements. Once the design enters the detailed design, making changes at the architecture level is nearly impossible, or at the very least, extremely costly. The V-Model figure highlights the location of the design gap.

Closing the gap with architecture optimization and verification

With the acquisition of Vitech, Zuken now has all the pieces to put together a model-based design chain for E/E subsystems – and close the design process gap. Vitech provides the model-based design tools, Zuken has critical architecture optimization and verification tools for electronic and electrical subsystems. Once the architecture for the Electronic Control Units (ECUs) and wire harnesses have been optimized and verified against the model, the design moves seamlessly into detailed design.

Why is the architecture verification so important? The system model is decomposed into an architecture comprised of subsystems (e.g., power train, infotainment, braking, etc.). Each subsystem is allocated or assigned a number of requirements, functions, and behaviors. This is what is commonly known as the design envelope. As an example, the power train architecture may call for 3 ECUs with a max weight of 6 lbs.

Using Zuken’s CR-8000 System Planner, the design team can construct an ECU to the level of detail needed for verification. At the same time, the team can reference the required functions and determine if they can accommodate the weight requirement. If the team cannot meet the requirement, the design team meets with systems engineering and may decide to eliminate one ECU to hit the weight target. This design change would then require each ECU to perform more functions.

Architecture optimization for wire harnesses is equally important in the design process. Imagine today’s automobiles with 100 ECUs and numerous wire harnesses. If multiple design teams missed the model requirements, the resulting vehicle may not look anything like what was defined in the model. If the architecture isn’t right, detailed design can’t fix it. Zuken’s E3.WiringSystemsLab provides this level of optimization for wire harnesses. Check out this webinar to learn more.

Digital engineering is becoming a reality

This is truly an exciting and disruptive time for the product development community. Digital transformation is happening at the corporate level and digital engineering is changing the way complex products are developed. We are excited for Vitech to join the Zuken family with their systems engineering expertise as we build the next generation model-based design chain.

Learn more about our digital engineering solutions

Also see: