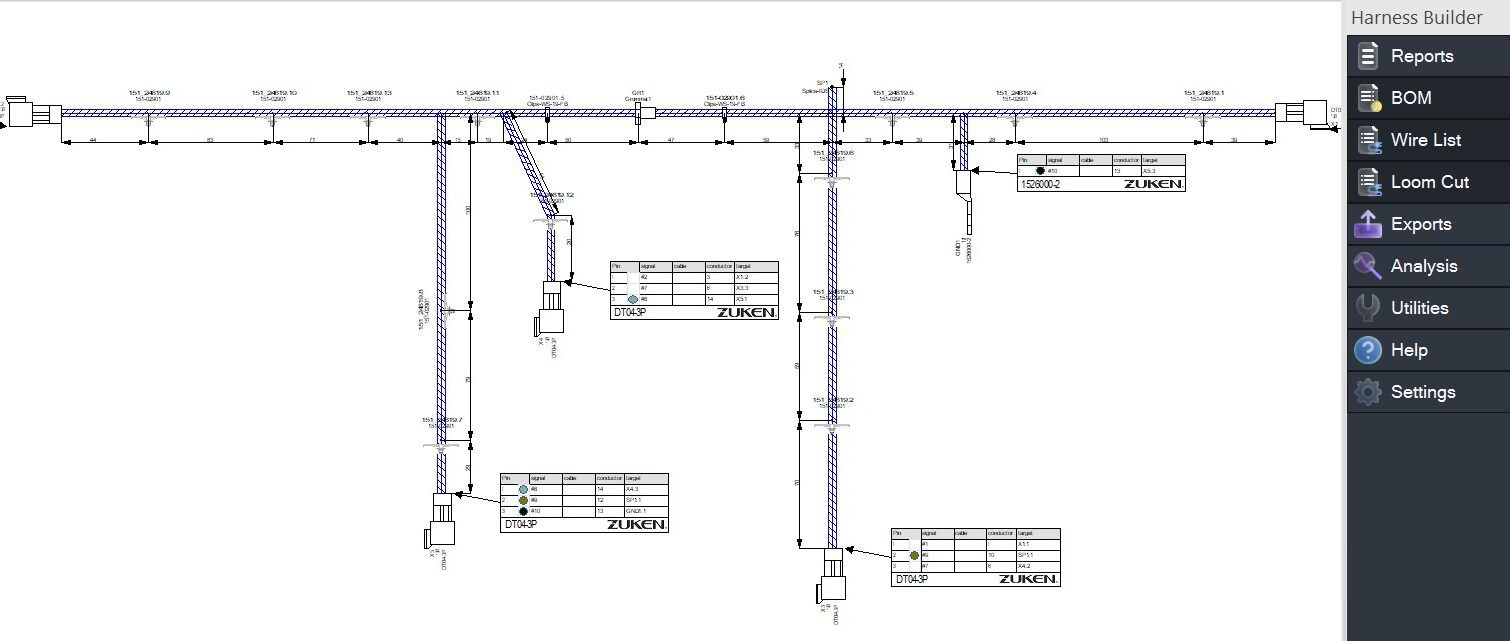

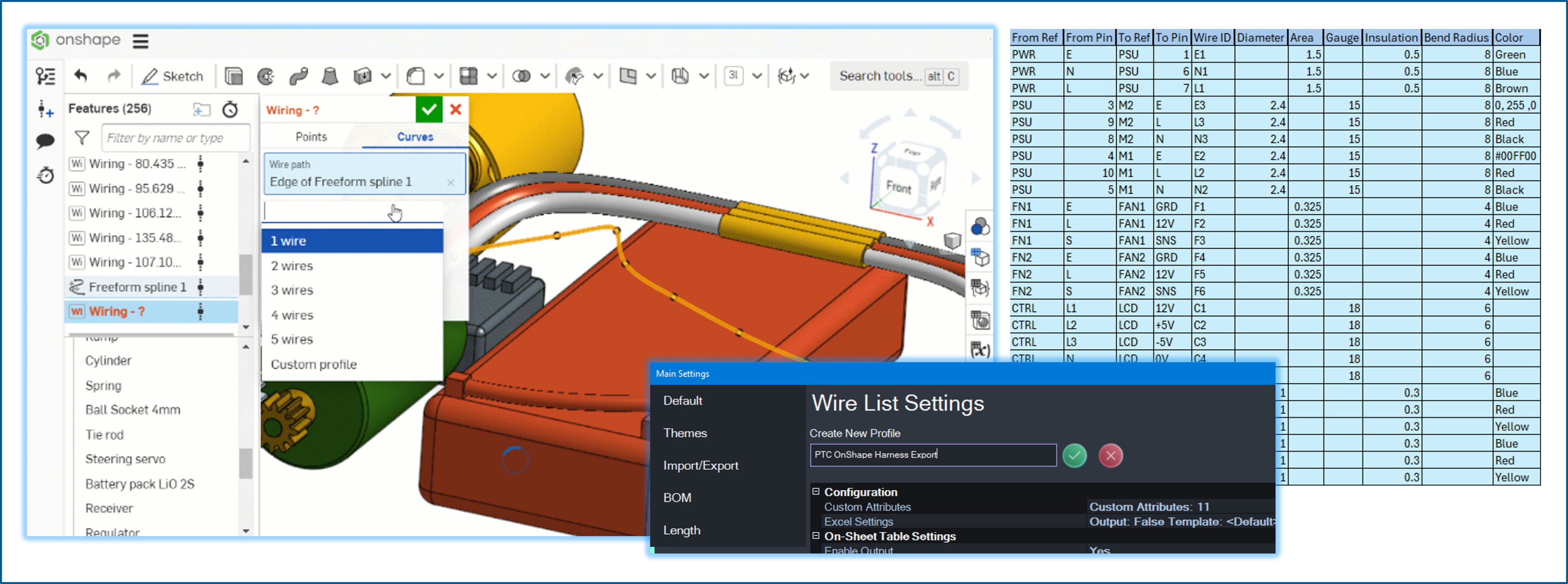

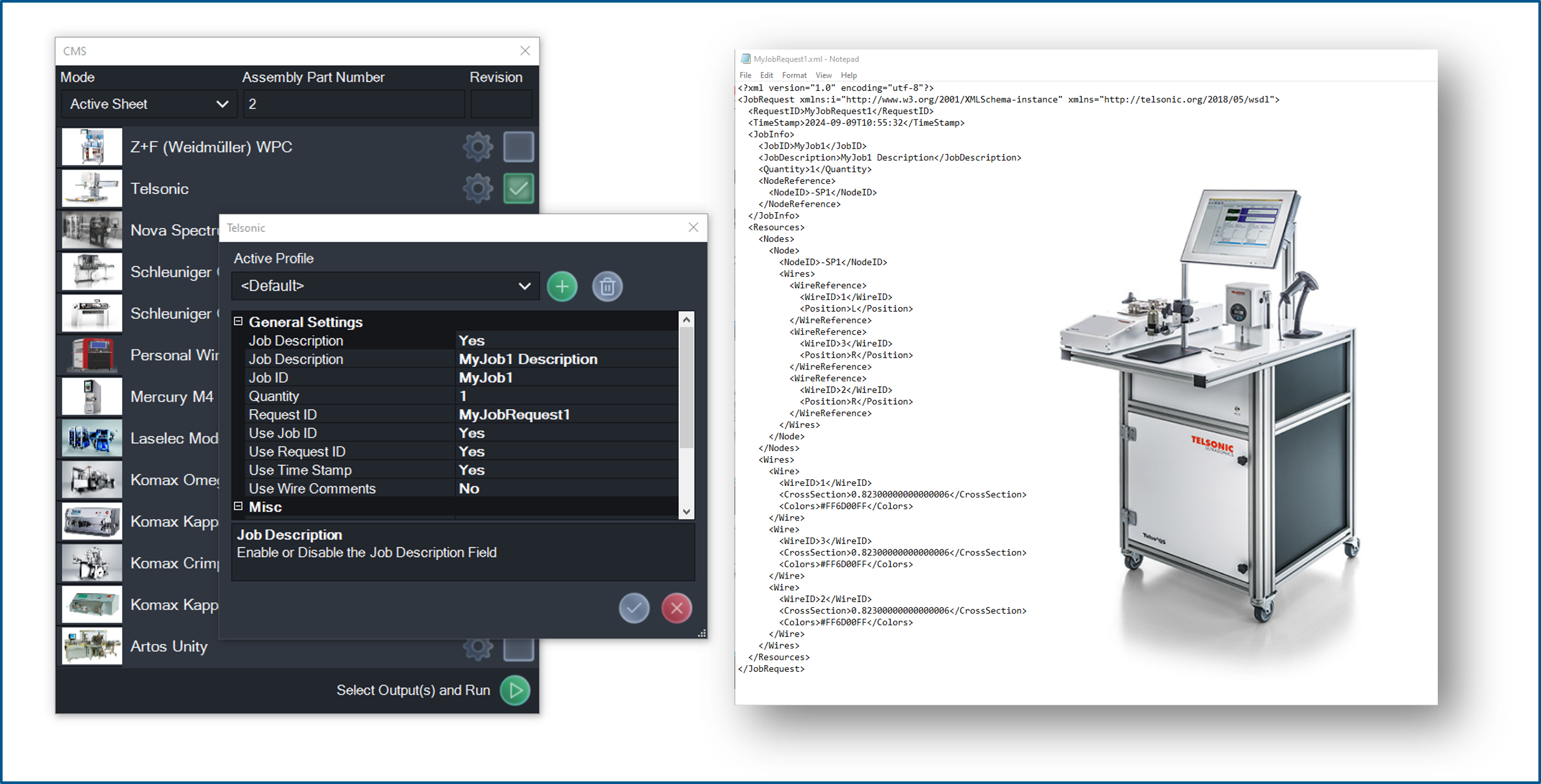

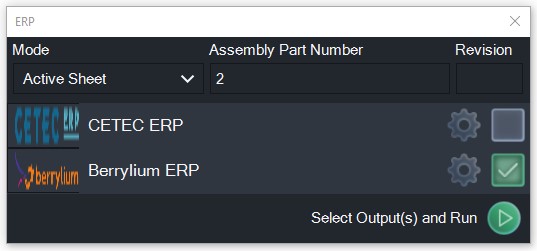

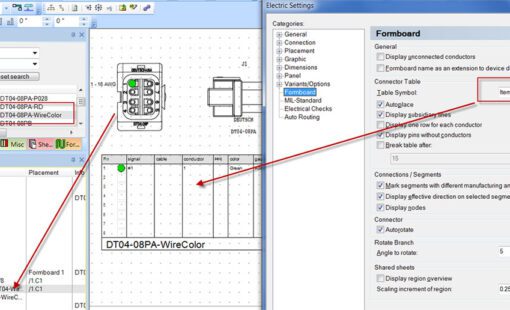

The 2025 release of Zuken’s Harness Builder for E3.series delivers an array of new features aimed at advancing design precision, reducing errors, and streamlining the manufacturing process. This version introduces enhanced integration with cutting-edge manufacturing equipment, improved design automation, and powerful export capabilities to tackle the increasing complexity of modern electrical systems.

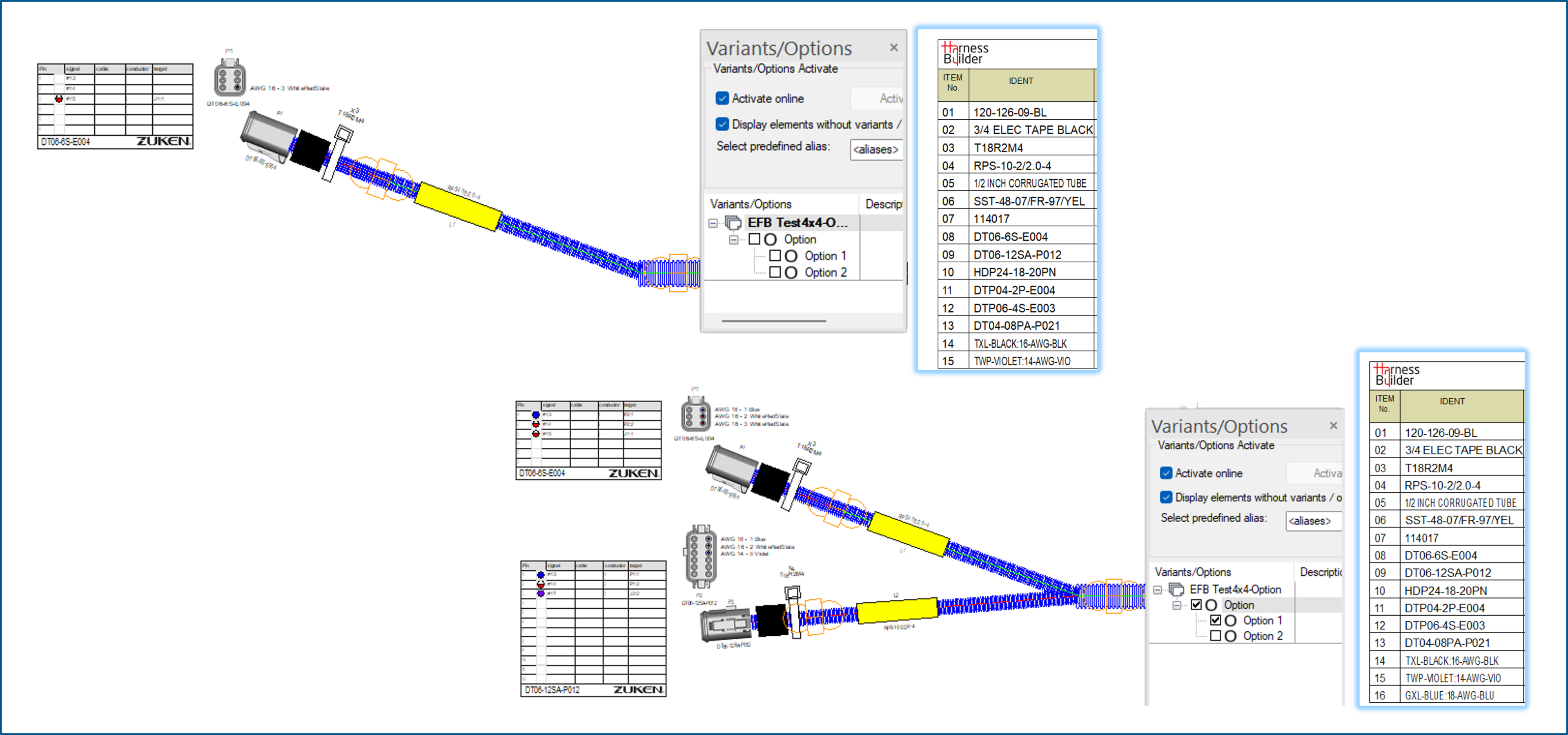

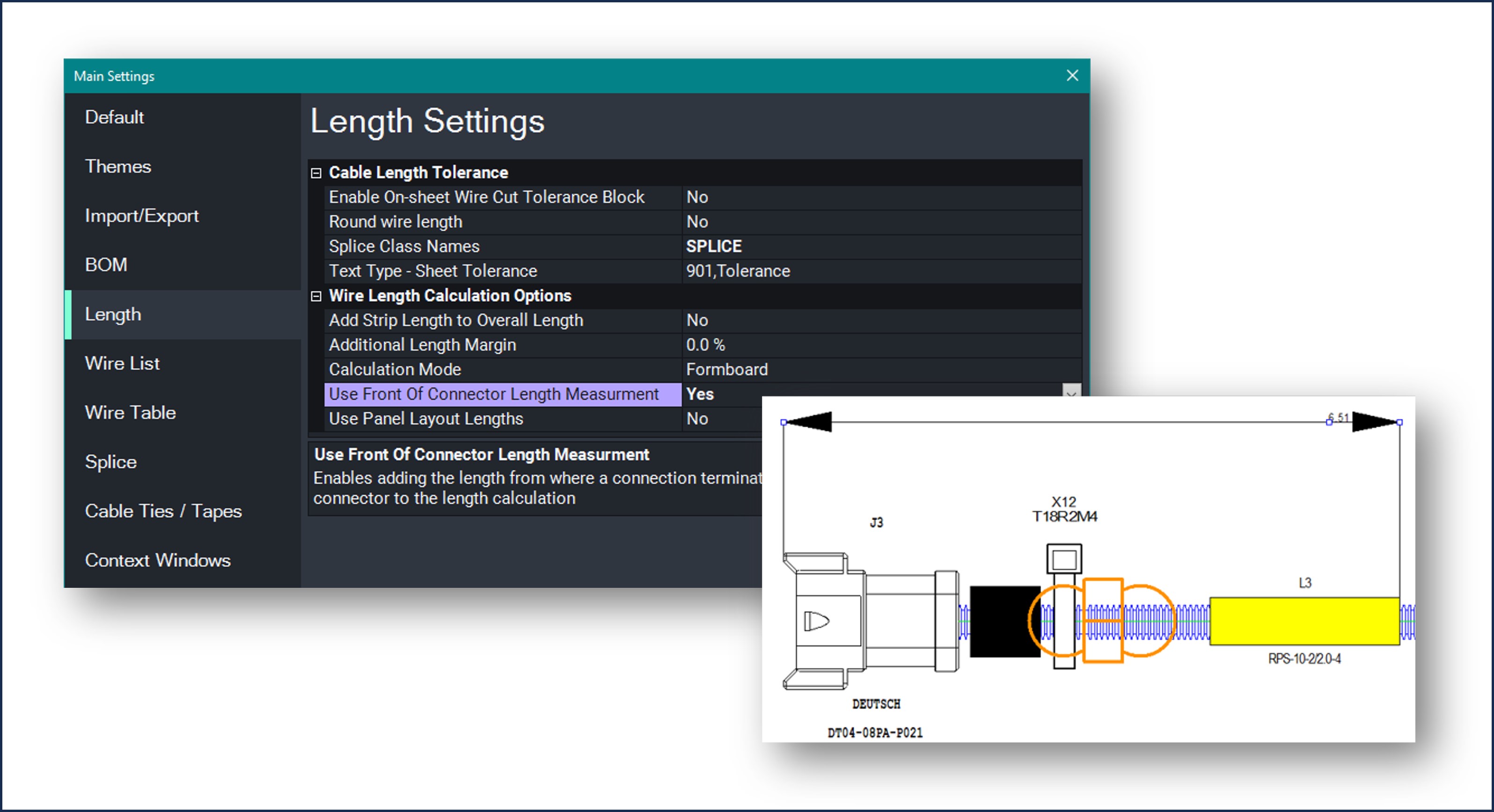

Our customers now have more flexibility and control with the new manufacturing equipment, MCAD, and ERP integrations. Additionally, the updates to handling options and variant configurations, dash numbers, and the new front of the connector length calculation factor, provide more accurate reports for quoting and manufacturing. The addition of new automation and enhancements to the formboard copilot will improve the user experience in designing harness drawings.