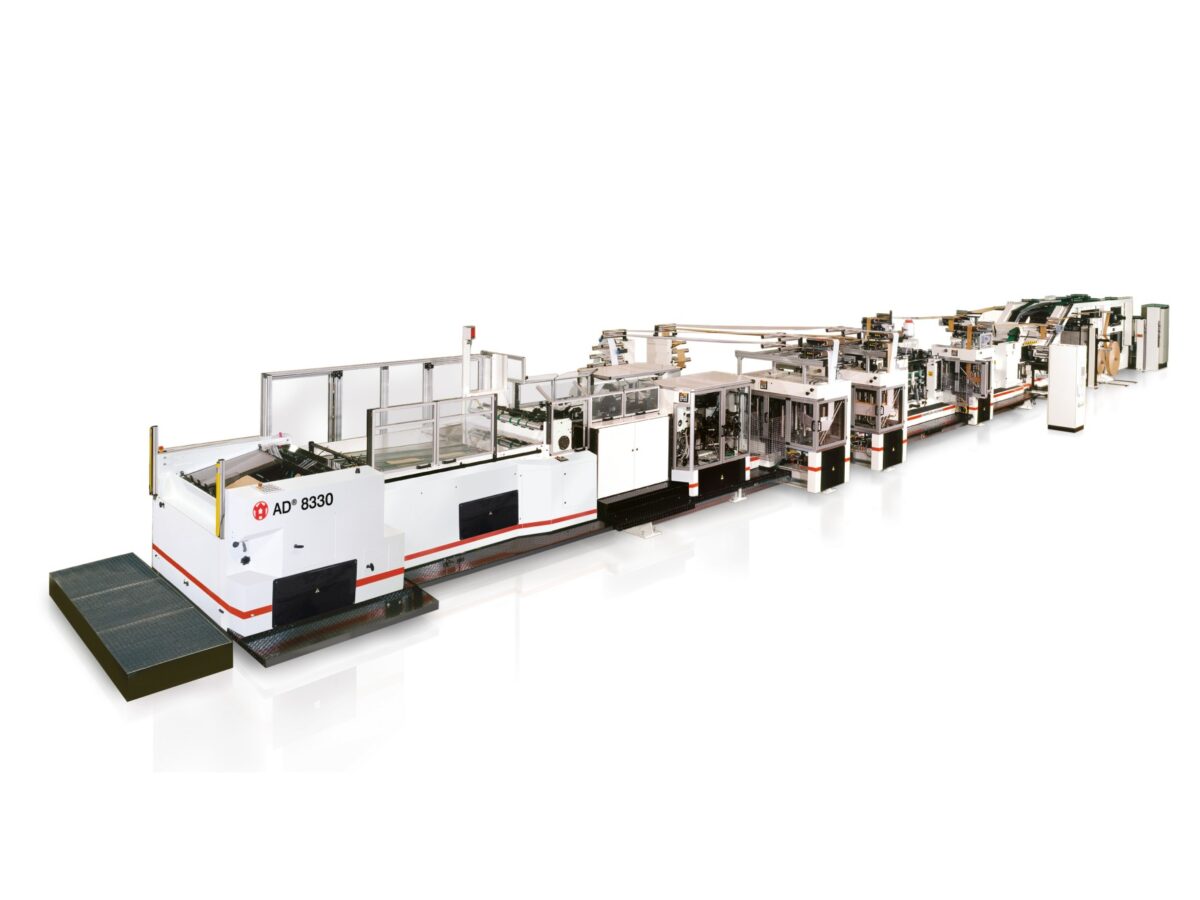

The German machinery company Windmöller & Hölscher, a world market leader for machines and systems for the production and processing of flexible wrappings, based in Lengerich, Westphalia, over the course of more than 30 years had built up an extensive inventory of project data comprising more than 18,000 data records with more than 1 million schematic pages.

As part of a system migration to E3.series from Zuken, this data pool needed to be converted in the most efficient way possible to be made available for continued processing.

18,000 data sets comprising more than 1 million schematic sheets.

Over the course of their operation, the machines for flexible packaging from Windmöller & Hölscher are regularly maintained and upgraded. “Consequently, it became necessary in the course of a system migration to the electrical engineering environment E3.series from Zuken to not only keep the circuit diagrams (electrical and pneumatic) accessible as a graphical representation such as PDF but also have them available for further processing in an object-oriented manner using Zuken E3.series,” explains Ralf Budke, IT Coordinator, IT Business Processes Windmöller & Hölscher.

A specific aspect of the task was that during its 30 years of use, the legacy system had been extended by a large number of adaptations/extensions/releases. This had become necessary to accommodate the requirements of machines that had become more and more complex over time. After the system change to E3.series, these extensions, which included the processing of cable lists, connection lists, component lists, and assembly diagrams for control cabinets, needed to be made available for further use in the design, production and assembly processes.

Fully automated data conversion enabled by a migration platform

The task was entrusted to Zuken, the company that had also supplied the E3.series design tools. For this purpose, Zuken has access to a team of experts who, in addition to extensive experience, have developed a powerful and highly flexible migration software, which has been refined over the years in the implementation of a multitude of projects.

An innovative and powerful database technology characterises the migration software used for the project with an export interface that is directly integrated into the target system. It is capable of reading and transferring a wide range of different E-CAD formats to Zuken E-CAD software, not only for E3.series but also for eCADSTAR and CR-8000 PCB design software.

The software is individually configurable so that specific features and extensions in the source system can be taken into account as rules and mappings, so that after defining the necessary settings, the actual transfer of the data into the target system, including accompanying quality control, can be carried out automatically in batch mode. After the conversion, the customer can read the data into the target system and continue processing it without any loss of quality or further adaptation.

A thorough preparation of the project lays the foundation for a successful automation

The initial analysis of the data pools and the setup of the configuration files proved to be a particular challenge in the migration of Windmöller & Hölscher’s extensive data pool, which had built up over the years:

At the beginning of the project, the total inventory of 18,000 projects of different years was analysed in detail and classified into packages: Packages 1 and 2 comprised approx. 6,000 older projects with a low to medium degree of complexity, Package 3 comprised a total of 12,000 projects involving extensive databases that required a higher effort for migration and quality control.

A specific requirement resulted from the migration of the multilingual language database from the source system. In the migrated E3.series projects, it is therefore now possible to select the desired customer language as required.

The E-CAD source system provided a large amount of important project data, such as cable lists, connection lists, component lists and terminal lists, in the form of CSV files. This legacy system data was read in and subsequently interpreted in the migration environment.

Another important element in the preparation for the actual data migration, was the extension of the import API interface in E3.series. The objective was the ability to directly import and convert the migration database into an E3.series object-related project.

The large number of projects, the long operating history of the source system and the new capabilities offered by the target system E3.series created a great deal of dynamism and required a high degree of flexibility from the project team of Windmöller&Hölscher and Zuken, which was supported effectively by Zuken’s agile software development.

Automated transfer in a batch process with integrated quality control

The actual implementation took place in a 24-hour batch operation with up to 10 processes running in parallel. The accompanying, largely automated quality control included checks of assemblies, connection data, cable data and component lists. The quality control evaluation was made available in the form of a results list that could be imported into the E3.series data management system DS-E3 along with the respective E3 projects.

The import of the projects themselves was also carried out in an efficient batch process, in the same way as the previous conversion. The imported projects into the E3.series engineering data management system in DS-E3 are now directly available as single-user or multi-user projects for further processing by the different departments at Windmöller & Hölscher.

“The teamwork with Zuken during the analysis, preparation and conversion of our legacy data was very efficient and reliable,” summarises Ralf Budke. “After we delivered our data, Zuken’s migration team immediately set to work with great motivation, so that all agreed deadlines were reliably met. Thanks to the migration, we are now able to continue to use our extensive database in a seamless manner – which is essential in particular in the service sector with its focus on the aftersales business, as it enables efficient troubleshooting, maintenance and expansions of existing client installations.”

- Seiten

- Products

E3.series ermöglicht einen effizienten und präzisen Gestaltungs- und Fertigungsprozess für die Elektroplanung und Fluidplanung, die Kabelplanung sowie den Kabelbaum- und Schaltschrankaufbau.