- Blog

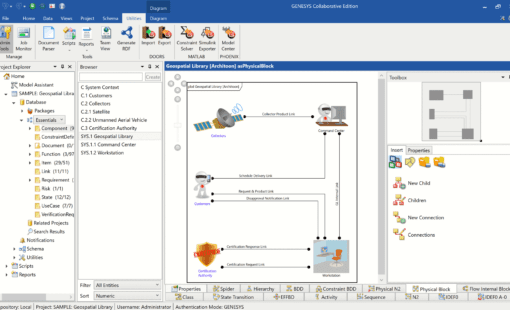

In this week’s blog post we’re sharing an exciting sneak peek of the 2021 R2 release of GENESYS, the latest version of our model-based systems engineering development platform, including a new language option and an extended API.

- Blog

Today, people are increasingly looking to the prospect of flying cars as a means of solving social problems such as traffic congestion in urban areas and transporting people and goods to mountainous areas or remote islands. While major automobile and aircraft manufacturers around the world are entering the market one after another, one university-derived start-up company is trying to challenge this increasingly competitive market.

- Blog

Alex Grove, Account Manager at Zuken, talks about his personal MBSE journey, what his customers experience when embarking on such a journey, and the upcoming Annual Systems Engineering Conference.

- Blog

Today's smart and connected products require the interaction of different components and systems. Their elements are developed in different engineering disciplines and departments. These disciplines speak different engineering languages and require unique views of the same product. The storage of these different versions in the respective departments leads to disconnected silos in terms of processes and data - but digital continuity is here to help!

- Blog

The whole world is buzzing about the digital transformation. Without a doubt, a megatrend - right? Many emerging phenomena are proclaimed to be megatrends by different sources. At times with good reason, at other times inflated by the subjective view of individual industries. So what distinguishes a megatrend from just a regular trend?

- Blog

A modular product approach is an established way of improving the calculating and realizing the value of investment goods. Yet modular product initiatives often fail to live up to expectations because of poor coordination between engineering disciplines. To deliver on the promise of a modular product architecture strategy, companies need to create a number of prerequisites in organization, process, and infrastructure.

- Blog

Electronics and mechanics are two of the most important areas of modern engineering. ECAD and MCAD are the generic names for software solutions that support the virtual design of electronic and mechanical systems in products. The integration of ECAD and MCAD design information and design processes is essential for the development of advanced electro-mechanical products

- Blog

Digital Transformation should go beyond a simple mapping of analog documents and processes into the digital domain. This blog post explores new ways and opportunities to enhance today’s methods and processes for increased efficiency and accelerated innovation.

- Blog

Many manufacturers are harnessing systems engineering approaches to mitigate the complexity of developing increasingly sophisticated products. Systems simulation is a key component of such efforts.

- Blog

As engineers face increasing complexity across electronics and electrical systems, they need a single set of related data to offer insights into the product’s various processes and functions. Simply stated, they need a digital thread for electrical systems.

- Blog

As engineers face increasing complexity across electronics and electrical systems, they need a single set of related data to offer insights into the product’s various processes and functions. Simply stated, they need a digital thread for electrical systems.

- Blog

The complexity of electrical and electronic (E/E) systems is accelerating across multiple industries and sectors. Manufacturers are adapting their design and development approaches to meet the changing requirements of advancing electrification.

- Blog

COVID has not only been disruptive to our daily lives but now we’re seeing the effects on our work lives as well. Companies are facing new challenges, from remote tool access to the purchase and distribution of new online tools.

- Blog

Thanks to advancing technology, products are becoming more feature-rich and in turn, more complex. They must incorporate sophisticated electronic and electrical systems to provide the interconnectivity and user experience modern consumers demand. As a result, many organizations increasingly rely on systems engineering.

- Blog

Products are increasing in complexity at an astonishing rate. Smartphones are just one example: today’s devices combine the functionality of yesterday’s phones, cameras, calculators, and pagers and place desktop applications and internet browsers in the palms of our hands. Advancing electrification, mass miniaturization, and IoT-driven digitization are making a vast range of devices smarter and smaller. To cope with these changes, manufacturers must transform the way they develop complex systems. This post compares and contrasts the traditional and modern approaches to developing and verifying products.

- Blog

There’s no doubt about it: products are getting smarter. And that translates to increasing complexity for manufacturers. Traditional mechanical products suddenly require cabling and wiring, internet connectivity, and embedded software to function.