Looking at Digital Continuity

Today’s smart and connected products require the interaction of different components and systems.

The good news is digital continuity as per definition is here to overcome this disconnection. It can integrate cross-disciplinary collaboration well; internally by connecting the different engineering departments and even externally extending the workbench with external partners.

What is Digital Continuity?

According to Capgemini’s manufacturing expert Guy Williamson, digital continuity is the “ability for everyone working on a given product or design to view the exact same version of data and models”. He even goes so far as to call it a “critical enabler” for smart and connected products.

A similar but slightly different approach in the definition comes from one of our customers Safran. They claim: “Digital continuity is the ability to have all of the data about a product, system or infrastructure, during the different processes in its life span. Development – Manufacturing – Maintenance.”

What we can take from these two definitions is that digital continuity means not only making product data available to everyone involved but also ensuring the completeness of the product data. And equally important, digital continuity doesn’t stop after product development. It rather continues to run through the following stages of the product lifecycle like a thread.

How to Achieve Digital Continuity Solutions for Product Development

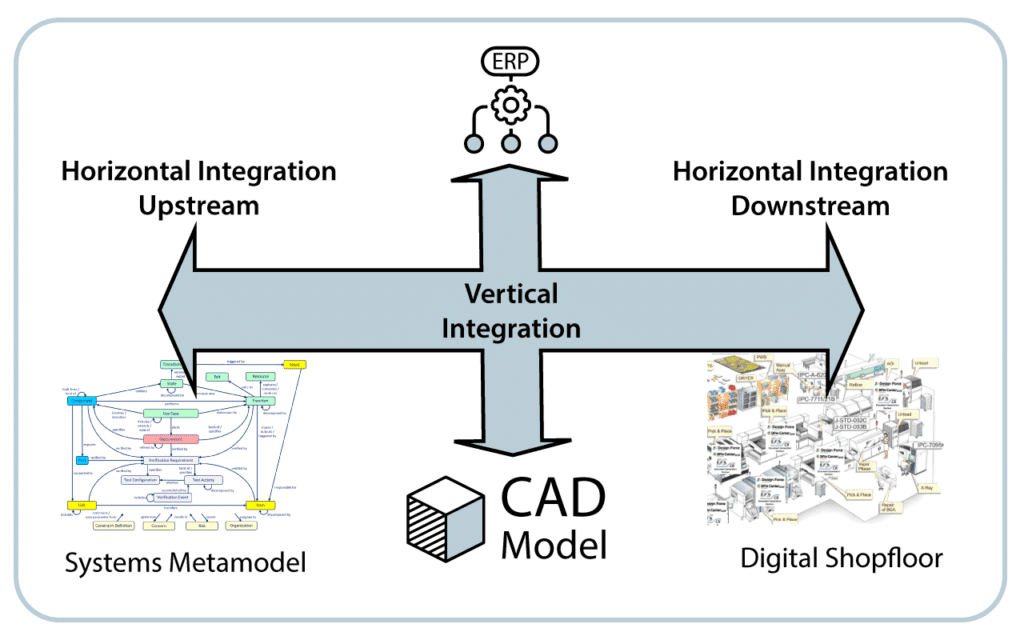

Let’s take a closer look at digital continuity for product development. The first step towards cross-silo networking and the ultimate goal of a digital continuity plan is integration. Organisations need a cross-disciplinary product model and the processes going hand-in-hand to create it. When we look at the product development process, there are two main types of integration: horizontal and vertical.

Vertical integration, for instance, connects a programmable electronic building block with related software and mechanical engineering areas. It also establishes the link to purchasing and stock management, taking into account business operations management (BOM) policies for preferred parts management in order to achieve optimum resource output. Horizontal integration links early requirements management with systems engineering and the downstream release of a qualified revision of the digitized product, right through to shop floor planning. Corporate process mining is a hot topic in that respect.

Process Mining – Tomorrow’s Buzzword?

Process mining is a set of methods from the areas of data science and process management. They expose available data from IT systems like an x-ray with the aim of evaluating business processes and identifying optimization potential.

After such an analysis, one common approach is to harmonize the processes that touch several departments in the end-to-end development process. However, each department or engineering domain often has its own specific language and design environment adding to the colourfulness of the design ecosystem. The call for unification by any means, even under the cover of harmonization, needs to be considered carefully.

This is not at all to say that harmonization is wrong. What I am saying is that there is a limit to what we can harmonize in an economically sensible way while sustaining a company’s ability to create innovative products. There is no one-size-fits-all solution – usually, there are as many different solutions as there are different problems.

The engineers of different departments need cultural (in the sense of engineering discipline-specific) and creative freedom (in the sense of flexibility) for the specific design challenges they face.

Engineering PDM and PLM Integration Strategy

Learn how we at Zuken can help you and your business solve the challenges of digital transformation in our on-demand webinar: ‘Digital Continuity – Engineering PDM and PLM Integration Strategy’. It includes more details on Zuken applications and process integrations from real-life use cases.