Engineers no longer need to create world-beating products independently. Today, projects require teams of engineers working across discipline lines. For projects with tight deadlines and constrained budgets, engineering data management has become as important as engineering itself. Best practices for engineering data management (EDM) dictate that the data management be real-time and easy to use, with controllable accessibility by all team members and managers.

Engineering Data Management Challenges

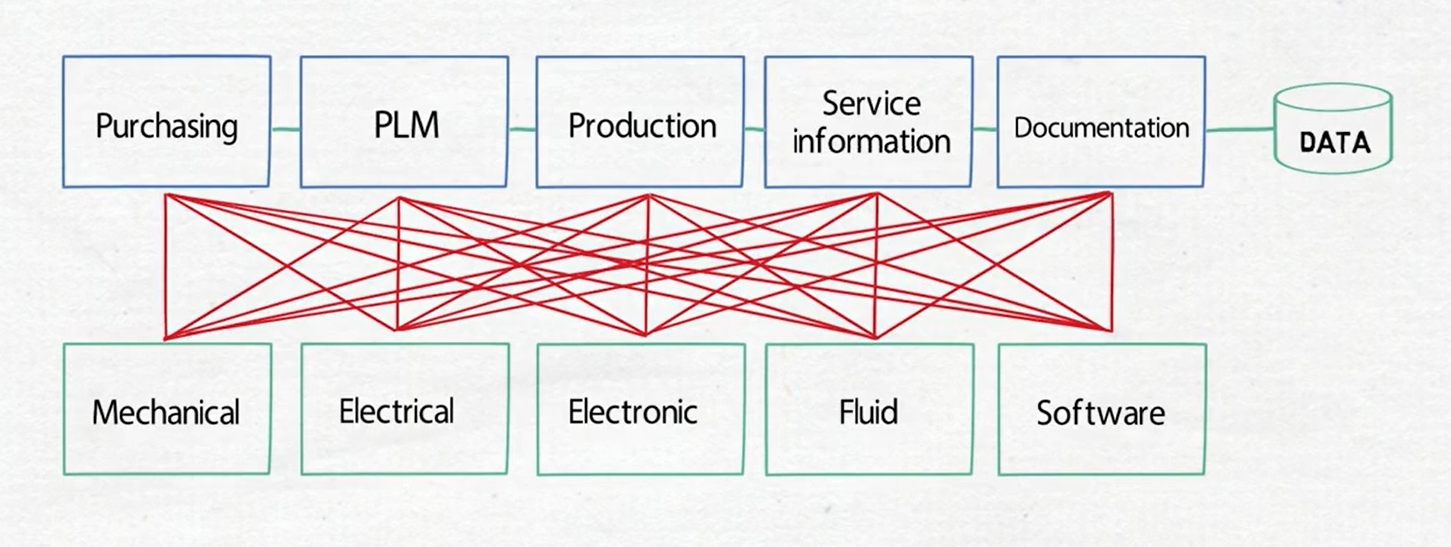

While the concept of cross-functional communication and data management is not new, many companies still struggle to find tools that can keep team members from working in discrete silos. Project information is needed by various departments throughout the development timeline, however, data is often misplaced, out of date, or incomplete.

The situation is aggravated by the fact that existing data management environments are not equipped to provide native electrical and electronic data management capabilities, as they are typically based on the requirements of mechanical engineering.

Failure to leverage effective strategies for design data management will almost always add cost and time. Resulting miscommunications could cause redundant development, with decisions being revisited at non-optimum points in the design cycle. To address this, Zuken provides a library and data management technology that has been designed to provide both reading and interpreting capabilities of ECAD data for comprehensive change and configuration management tasks, and the ability to integrate into existing PLM environments such as PTC Windchill, Dassault 3D Experience or Siemens Teamcenter via SOAP-based plug & play connectors.

In this way our solution is designed to answer the needs of both electronic and mechanical engineering teams to enable a true electro-mechanical data model, ideal for optimizing data management for engineering projects software.

What is Engineering Data Management

Engineering data management is a holistic approach to acquiring, validating, storing, protecting, and processing project relevant data. This way, accessibility, reliability, and timeliness can be ensured for data use during and after project completion. Effective design data management operates much like software code vaults, storing all pertinent data for a project.

Best practices for engineering data management start with a comprehensive strategy. This should include a vision for how a data package will be used during development, after development, and the duration it will be needed post development. Additionally, the strategy should specify the type of data, access control, and usage discipline.

Furthermore, data management systems must equally accommodate remote and on-site workers, as well as those from partner companies. The design data management strategies must adhere to these restrictions without impeding developer progress with outstanding overhead.

Design Data Management Strategies: Single Vendor vs. Multi-tool

Selecting a single vendor or a heterogeneous, multi-tool approach is an important decision for design data management strategy. Several well-known PLM platform providers advocate for a single vendor approach to PLM and data management. However, this advocacy benefits the providers more than the customer. Realistically, most design organizations will find themselves using suites of tools from multiple suppliers that they will find extremely difficult to “shoehorn” into a single vendor environment.

A holistic strategy that will accommodate a wide variety of tools from multiple vendors ensures that the depth of the data is consistent for all users and disciplines. This will prevent the situation of data outliers that can only be accessed through spreadsheets or a vendor proprietary interface, separated from the majority of data stored in a singular repository.

Four Key Aspects of Engineering Data Management

The primary objective of having a robust engineering data management system is to improve the final product delivery. Engineering data management starts at the strategic level with data governance decisions, including access and management policies. Data stewardship follows with the oversight and implementation of a data management policy. Structuring the data systems enters the tactical realm. Finally, architecting the analytics and quality assurance rounds out the strategic prefix to the engineering data management program.

Cross Functional Alignment and Agreement to Adhere

Prior to the project start, team members from all functional groups must be trained in the data management system. Each will be given access based on “need to know” parameters of their function. For example, a design engineer will be able to add a part to the component management database. On the other hand, a purchasing agent will only be able to edit a component with pricing and availability.

Regulatory Impact on Data Management

In addition to operational needs, regulations covering security protocols and data integrity are becoming a more notable factor in engineering data management. With teams often dispersed across multiple facilities in different countries, security and integrity become increasingly challenging. Many industries, including automotive, medical devices, aerospace, and defense, are subject to regulation and compliance standards for data control and management. Regulations cover control of data access and security, as well as sometimes decades-long lifetime data store maintenance.

A comprehensive data management system must allow for a secure role-based access across multiple facilities or even across the globe. The best systems can effectively offer both geo-fencing and access-level controls so that data is only accessible in areas where it is allowed, by whom it is allowed. The systems must maintain the integrity of data for the support or regulatory life of the product.

Optimizing Data Management for Engineering Projects

Mechanical and electrical engineering data management create additional challenges due to the likelihood of such projects having different mechanical and electrical data formats from wide variety of vendors. Without proper adherence to best practices for engineering data management discipline, BOM integrity can be easily lost. BOM management must be multi-level and capable of maintaining a record of changes in addition to access control. After the design, the BOM tool must integrate with purchasing to ensure an accurate transition of data from development to manufacturing.

Zuken’s Design Data Change and Configuration Management Platform

With DS-2 technology, we provide a unique engineering data management platform tailored to the specific needs of electronic engineers, that allows for controlled access to remote, in-house, and hybrid teams. The platform was developed with more than 3,000 partner companies world-wide. Through its integrations into the PLM and ERP world , it allows electrical, software, mechanical, and electronics design teams to share data and coordinate design data and workflow information access.