The excitement of the 2020 release of Harness Builder for E3.series continues with Part 2 of our what’s new blog post. Harness Builder for E3.series is a purpose-built tool for enhancing the harness creation process. Automating the process right from the quote to prints on the formboard has always been the focus. Every step taken over the years gets us closer to the day we can fully automate the design of a harness.

We are closer than ever to a perfect design-to-manufacturing solution for simple and complex harnesses alike. In fact, the Harness Builder 2020 for E3.series release has more than 15 significant enhancements. Also, there are numerous minor improvements as well. Part 1 of this post highlights the design, testing, and manufacturing automation topics. These updates are a direct result of meticulous consultation with our customers, notably, the best industry experts. The real-world challenges presented by customers are a pleasure to resolve, and in doing so, we work our way towards a complete and reliable solution. Read Part 1 of this two-part blog post here.

In this post, we will cover the following 2 categories of updates

- Expanded automated report generation

- Automated harness detailing

Expanded automated report generation

Harness Builder for E3.series generates high-quality reports for various quoting, design, and documentation related tasks. Notably, the reporting capabilities of the solution are the most revered features. Therefore, the expansion of report generation capabilities comes as a surprise for most users – an excellent and exciting surprise – but a surprise nonetheless.

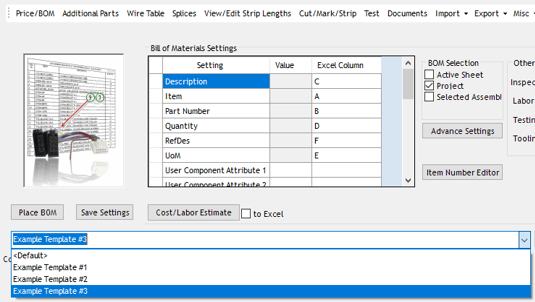

User-defined templates and configuration

The New selection options for user-defined templates enable the creation of multiple types of BOMs and WRLs. So, the report creation process does not need extensive configuration. For instance, now it’s easier to produce reports for purchasing, assembly, and manufacturing. The process is intuitive and straightforward. First, add the templates in Harness Builder for E3.series in the selection option. Second, select the desired template from a simple drop-down menu. Third and the most natural step, click the button to generate the report.

There are many other additions to augment report generation. For instance, the Excel report enhancement improves the quote generation process. The new functional placeholders improve the fidelity of the quote generation process. Lastly, new configuration and column options improve customization and versatility.

In contrast to the additions, interdependency between on-page and Excel BOM has been removed. In other words, we can now generate the on-page report, and the Excel reports independently of one other.

Easily edit and reassign item number

Reassigning and renumbering the items is easier than ever with a dedicated BOM Item Manager. It is a simple and effective tool to make minor manual edits to the order of items in the BOM.

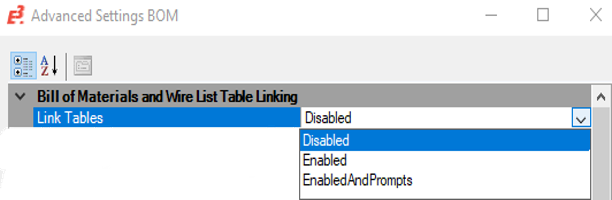

Keep the BOM and WRL in sync

In a harness, the wiring list and the bill of material are invariable interlinked. The latest addition to Harness Builder for E3.series indeed links them together and makes it possible to keep the reports in sync. The reports can trigger one another. Therefore, one updates the other automatically. In addition to automatic updates, the settings allow for updates with prompts.

The main benefit of the feature is to maintain consistency and improve accuracy. That is to say, as and when the wiring updates the BOM must update as well. Thus, we can ensure the wires, end treatments, and any other dependencies are up to date in the project reports.

The video below describes many amazing features and enhancement in reporting available with Harness Builder 2020 for E3.series.

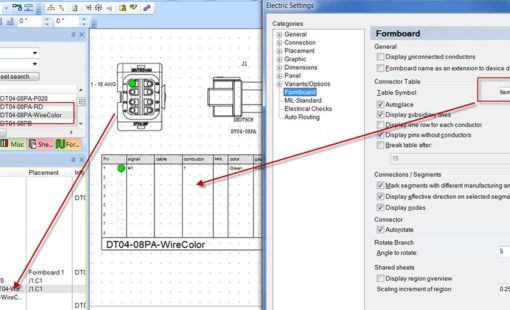

Automated harness detailing

The Harness Builder for E3.series team is always striving to reduce manual work. The goal is to reduce errors and remove the guesswork from the design process. In other words, capture the design intent and improve consistency.

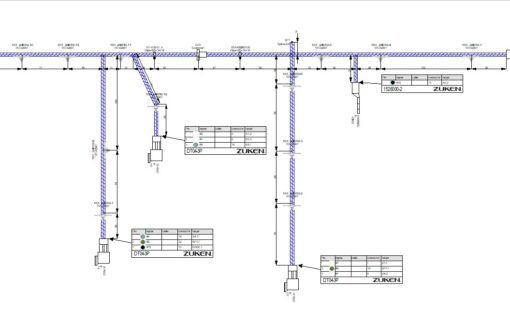

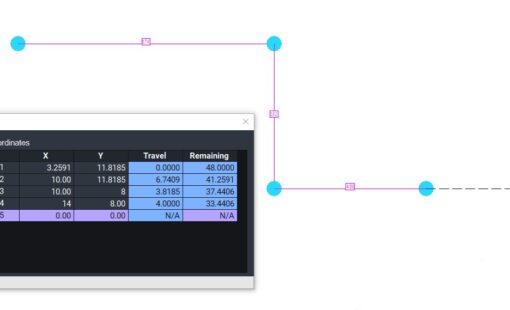

The harness design process is complex and requires attention to detail. Firstly, it is crucial to pay close attention to the logical connectivity and other technical details. Secondly, documentation must include details of connector pin, connectivity, and wire information. Thirdly, within spec maintenance of harness length, bend radius, bundle diameter, and splice thickness is imperative.

Furthermore, the designer must track cable protection, taping, and labeling requirements. The accurate matching of harness bundle diameter with the size of the harness accessories is imperative. The automatic segment bundle diameter check improves the overall quality of the design. So, it is safe to say, the automatic placement options in the Harness Builder 2020 for E3.series release are revolutionary.

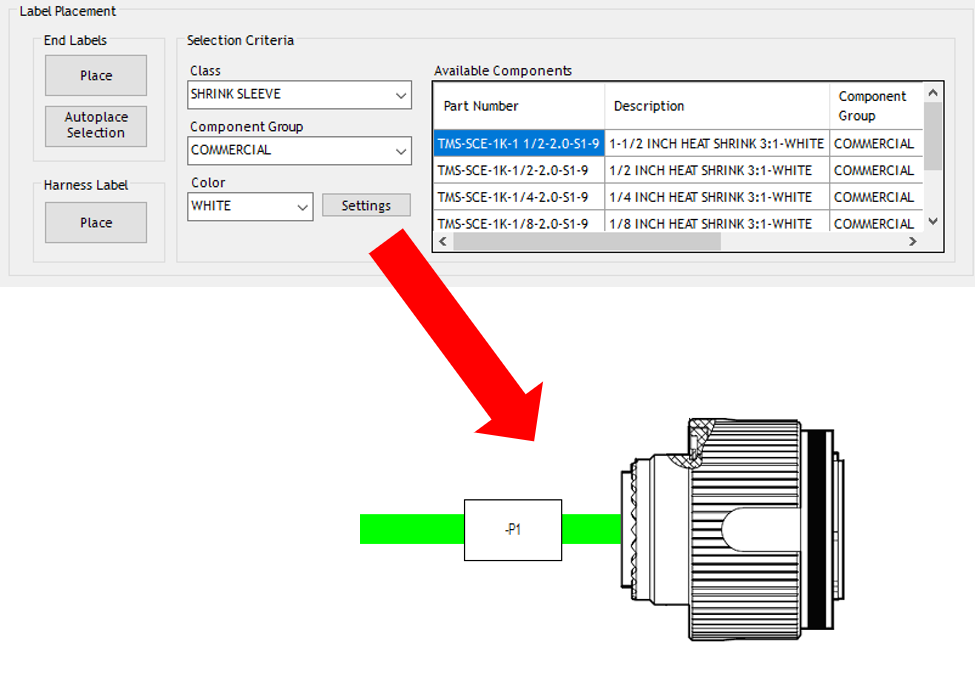

Label placement

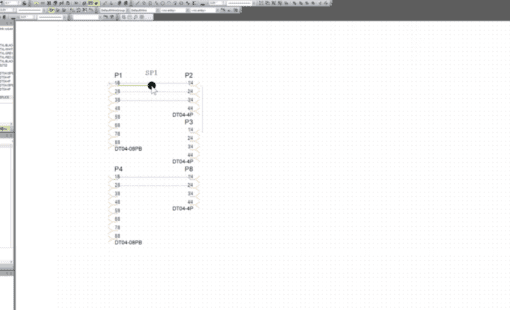

The automatic label placement option in Harness Builder 2020 for E3.series is a versatile tool. It not only saves time but also effectively standardizes harness designs across projects. In addition to harnesses, standard devices and connectors are the primary drivers of the labeling requirements. The multi-level selection criteria make the label definition flexible and effective across projects.

The label placement solution is versatile and provides complete auto place options as well as an individual placement option. The labels are configurable as independent parts or as additional parts of the devices. Moreover, it is also capable of assigning heat shrinks to device and connector terminations.

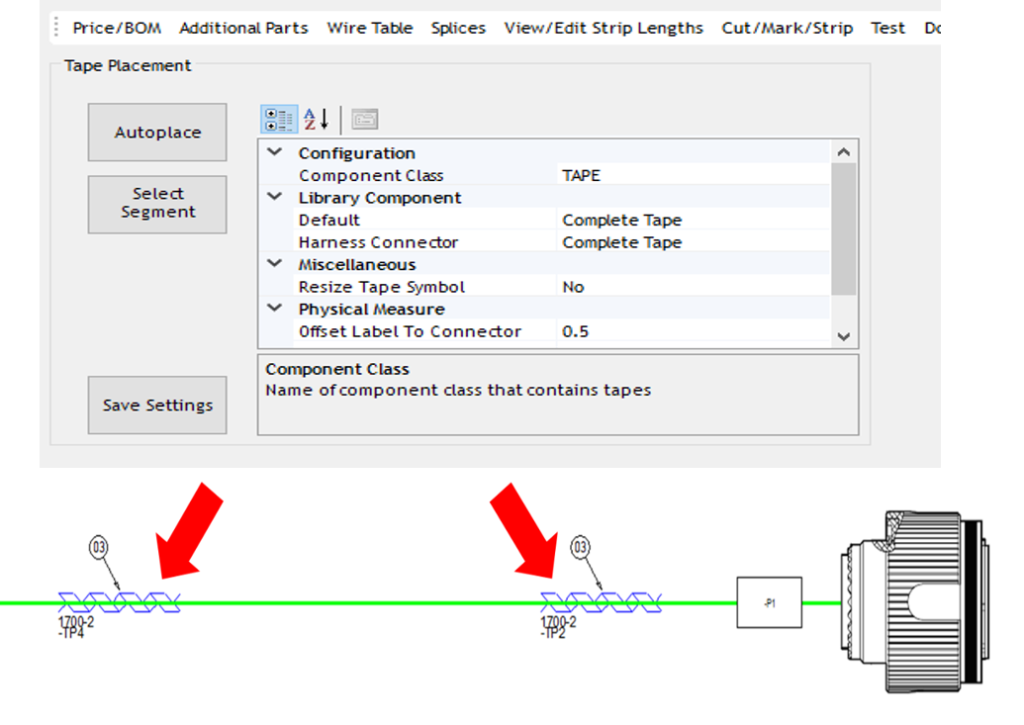

Tape placement

The placement of tapes, similar to labels, is typically a manual process. The latest update to Harness Builder for E3.series automates the tape placement process. There are two placement options: automatic and manual. The automatic option selects and places the tape, based on the configuration. Most importantly, the selection process intelligently calculates the diameter and selects the most appropriate tape.

Moreover, the tape placement is configurable with offset, centering, and various selection standards to match process requirements. The manual option adds precise control while still calculating the segment diameter. Therefore, tape placement in both modes is effortless and effective.

The video below showcases the unmatched time savings possibilities using auto-select and autoplace options for harness detailing with Harness Builder for E3.series.

- Products

Harness Builder for E3.series enables wire harness manufacturers to create accurate quotations and comprehensive manufacturing documents, and to drive wire preparation, assembly and testing machines.

- Products

E3.series is a true concurrent electrical engineering environment supporting advanced requirements for electrical documentation, cabinet and wire harness design and manufacturing outputs.