In the fast-paced world of discrete manufacturing, accelerating processes is a key to success. However, fast processes alone do not automatically ensure quality results. As the famous quote goes, “Garbage in, garbage out”. When you automate a garbage process, all you get is a fast garbage process.

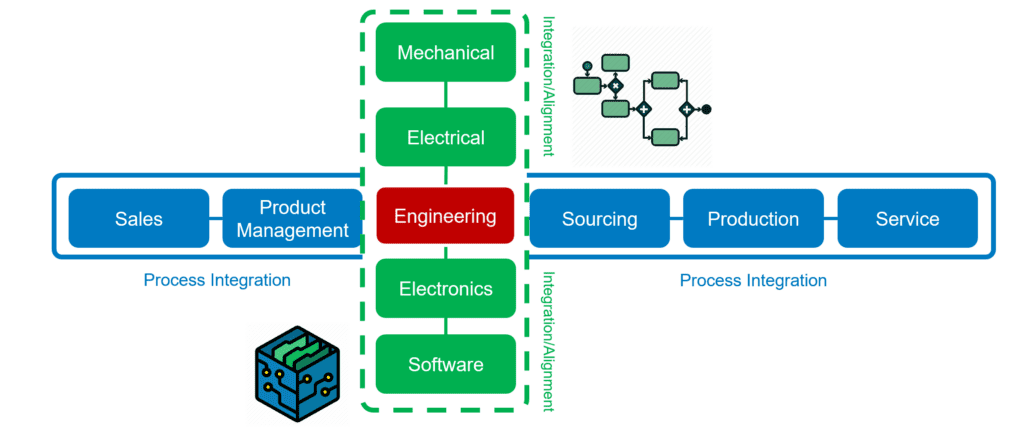

Product development is a collection of multiple processes: There are decision-making processes starting from requirements qualification down to functional specification and detailed engineering in the domains of electrical, mechanical, and software engineering. There are processes along the value chain from requirements specification to suppliers all the way through sourcing, delivery, quality assurance, and production.

Every single one of these processes involves a complex network of inputs, communications, and decisions between multiple stakeholders which needs to be controlled and managed. Optimizing these processes and the way they interact is therefore a good idea – and using the methods and tools of model-based systems engineering (MBSE) can help achieve better outcomes.

The Importance of Choosing the Right Strategy for Process Optimization

Product development processes can be optimized in various ways, depending on the desired goals. These goals may include speed and efficiency, maximizing output, ensuring product quality, complying with standards and regulations, or optimizing costs. However, choosing the right optimization strategy is not always straightforward. For example, prioritizing speed and throughput might lead to compromised product quality. For this reason, it is essential to evaluate the potential negative side effects that may arise from the chosen strategy. How can this be done?

Visualizing and Understanding Complexity

The processes involved in product development are inherently complex and interdependent. Different engineering methods exist within various domains such as mechanical engineering, electronics, and software. Additionally, different departments along the value chain, including sales, product management, application engineering, sourcing, production, and service, have their own workflows and optimization strategies.

Processes and information flows can be visualized in models. In the same way as the model of a product helps to visualize its functions and dependencies, the model of a process helps to understand bottlenecks by simulating it.

The Benefits of a Modelling Approach

A model-based approach to product development offers the promise of transparency and visibility. Models provide a comprehensive understanding of all dependencies and enable decision-making that considers both the product and its associated processes. By leveraging models, teams can gain insights into the intricate relationships between various elements, identify bottlenecks, and discover optimization potential.

-

Identifying Bottlenecks

Modeling processes help to pinpoint areas where inefficiencies and bottlenecks exist. With this knowledge, teams can focus on optimizing those specific areas, leading to improved overall performance. -

Discovering Opportunities for Optimization

Models reveal optimization opportunities that may otherwise go unnoticed. By visualizing the entire process flow, it becomes easier to spot areas where changes can have a significant impact on speed, quality, or cost-effectiveness. -

Improving Cross-Department Collaboration

A model-based approach encourages collaboration and knowledge-sharing across departments. By creating a shared understanding of processes and their interdependencies, teams can work together to develop efficient solutions and improve overall outcomes.

Embracing Process Optimization with MBSE

In product development, optimizing processes is a crucial step toward achieving success. Relying solely on speed without considering the quality and efficiency of the underlying processes can lead to undesirable outcomes. By adopting a model-based approach, organizations gain the necessary visibility to identify bottlenecks, uncover optimization potential, and make informed decisions that balance speed, quality, and cost-effectiveness. Remember, making bad processes faster will not give you good processes. Instead, focus on optimization as the foundation for integration and automation in product development.

Further Reading

Process optimization is just one of the many use cases for Model-Based Systems Engineering (MBSE). Download our Whitepaper How to use MBSE as an approach to solving critical challenges in the discrete manufacturing industry to receive a comprehensive guide to mastering product and process complexity with the help of a practice-oriented MBSE-based solution.