Dealing with complex requirements has become a common challenge in the discrete manufacturing industry, which is further aggravated by the advance of electro-mechanical content in modern products. The resulting requirements complexity is often referred to as the requirements trap: The more complex the product, the more convoluted the requirements process becomes.

Traditional methods of requirement document-based requirements description fail to provide the agility and clarity needed for successful product development. By adopting a model-based approach to requirements management, organizations can regain velocity, reduce risk, and ensure that products meet their customers’ specifications.

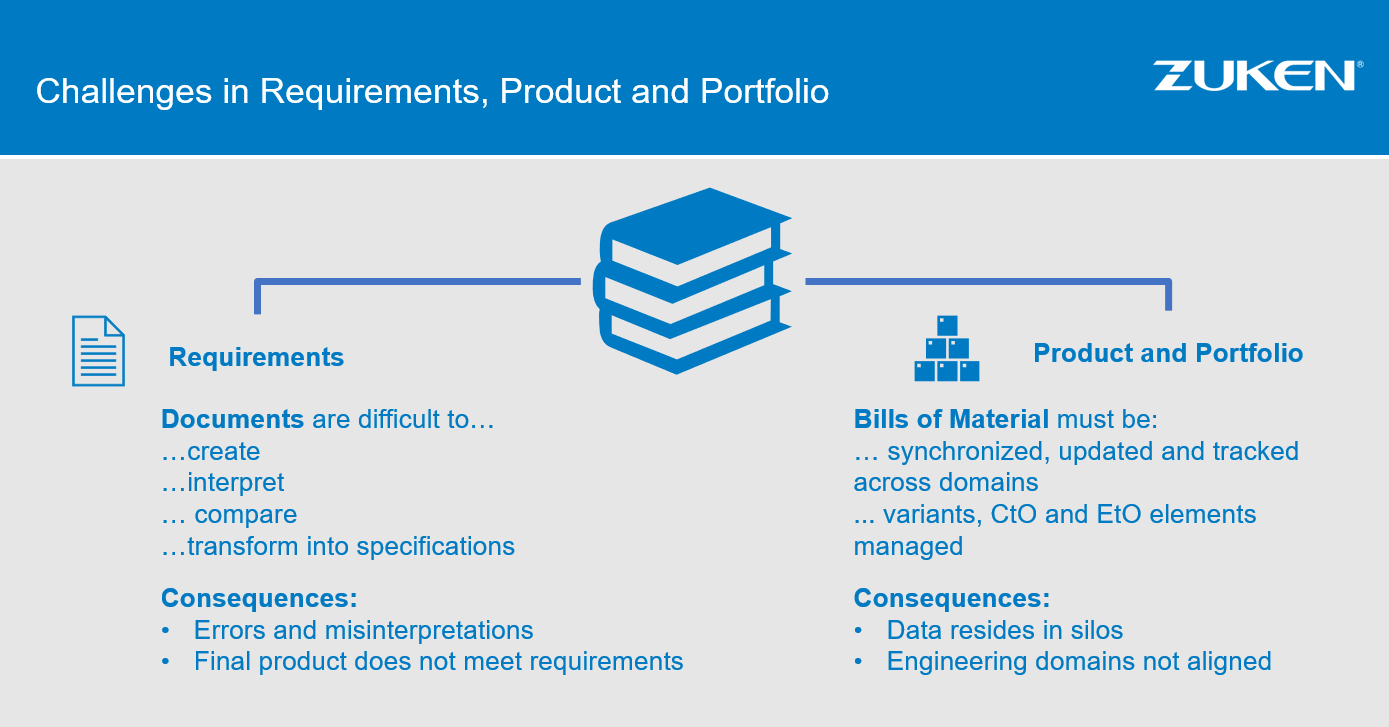

Challenges of Document-based Requirement Evaluation

Requirements documents pose significant challenges due to their length and complexity. They often become convoluted and difficult to understand and interpret correctly. Extracting the crucial product features from such documents becomes a daunting task. Furthermore, translating them into product specifications introduces another layer of complexity that requires careful understanding and interpretation.

Agile methods have gained popularity in software development, but they don’t always translate seamlessly to manufacturing. While efforts have been made to adapt agile principles to discrete manufacturing, certain challenges persist. The traditional requirements approach hinders the flexibility and adaptability that agile methodologies seek to foster.

The Solution: Model-Based Requirements Management

To escape the requirements trap, companies should consider shifting away from documents and embracing model-based requirements management. This approach allows for structured requirements and dynamic connections with engineering. By using models as a central representation of requirements, companies can overcome the limitations of documents and enhance speed and visibility throughout the product development lifecycle.

Implementing a model-based approach offers several advantages for discrete manufacturers. Increased speed enables rapid iterations and shorter development cycles, allowing companies to stay competitive in a fast-paced market. Increased visibility ensures a clear understanding of product requirements and enables effective collaboration between cross-functional teams. By adopting this approach, manufacturers can align their processes and foster a culture of innovation and continuous improvement.

Further Reading

Requirements clarification is just one of the many use cases for Model-Based Systems Engineering (MBSE). Download our Whitepaper How to use MBSE as an approach to solving critical challenges in the discrete manufacturing industry to receive a comprehensive guide to mastering product and process complexity with the help of a practice-oriented MBSE-based solution.