The key to digital continuity

In the race to industry 4.0 consistent data is vital for successful digitalization. One of the biggest threats are data silos. Data silos describe the storage of data that remains under the control of one department. Therefore it is typically isolated from the rest of the organization or lives on network folders that have no access control, read-and-write or version control.

However, access to reliable, up-to-date, and consistent data is essential in modern product development that requires close cross-discipline cooperation.

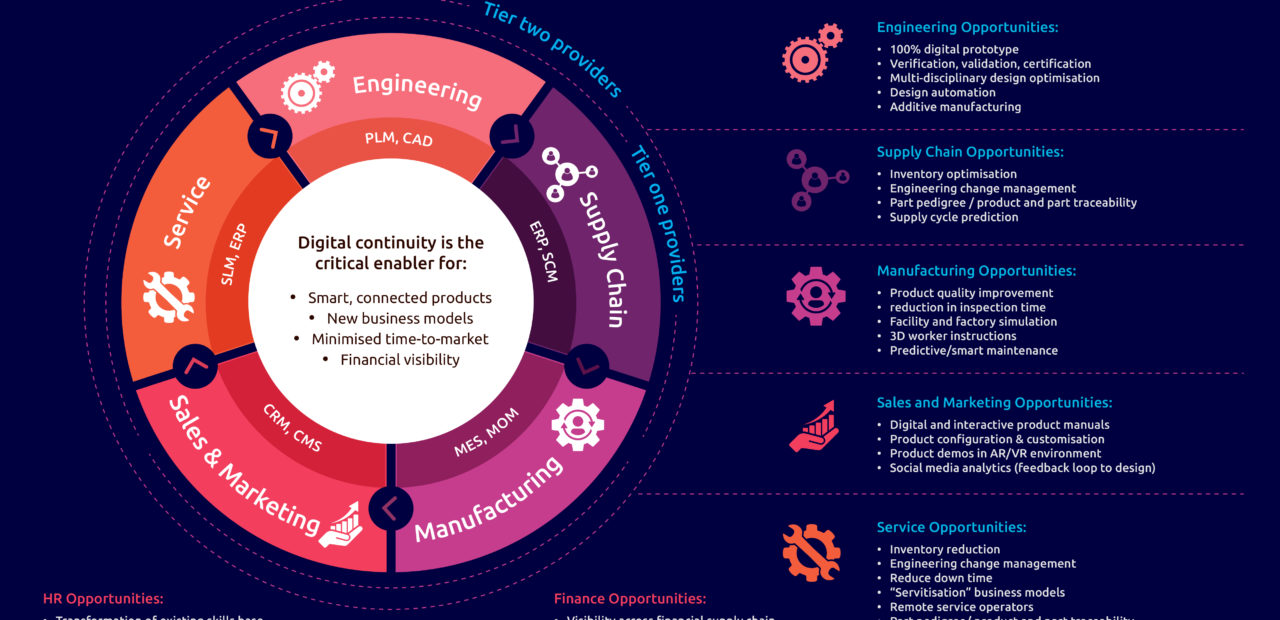

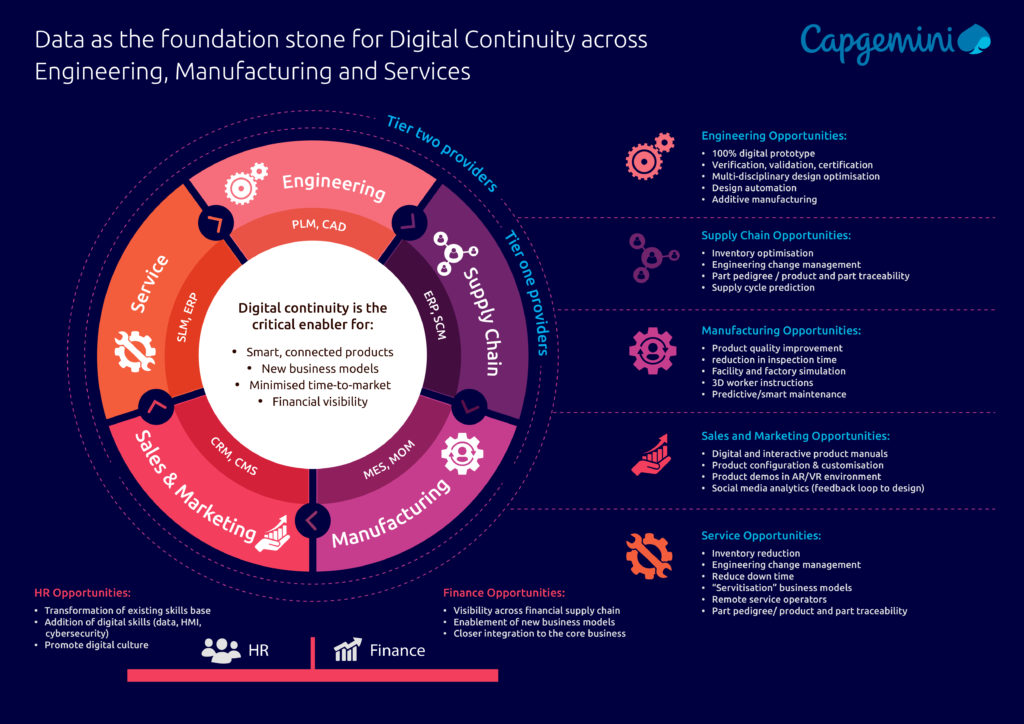

Here, the term digital continuity comes into play. Digital continuity describes the ability of everyone working on a given product or design to view the exact same version of data. It helps prevent data silos and acts as the “critical enabler” for smart, connected products, new business models, and faster time to market. Organizations need to take proactive measures to ensure digital continuity. Otherwise, information can easily become unusable.

Of course, there are many ways of ensuring and establishing digital continuity. In any case, it involves networking of different systems, repositories, and formats. For example the support for Engineering Change Management and Configuration Management for mechanic, electric/electronic, and software design. Or often from monolithic to federated and light-weighted systems based on Model-Based Repository and linked data technology (REST and/or WEB services).

The vision of a connected future

A preferable way to establish digital continuity is cross-system integration. This is provided by the recently announced integration of DS-2 into Dassault’s 3DEXPERIENCE platform (see Press Release). DS-2 is Zuken’s platform for electronic and electrical domain data management systems.

This integration enables joint customers to capitalize on a unified and consistent interdisciplinary product lifecycle management solution that provides breakthrough capabilities. Such as cross-discipline systems engineering and traceability, global systems partitioning, and navigation. All of the above are ultimately helping customers to maximize business improvement through digital continuity from concept to delivery.

Dassault’s 3DEXPERIENCE platform provides intuitive 3D applications for product design, analysis, manufacturing and data management in a digital environment. The 3D design simulation connects the digital world to the real world at an early stage of the product development process.

Through a bidirectional integration, Zuken’s electronic lifecycle management environment DS-2 can be integrated into the 3DEXPERIENCE platform in a way that components can be created and versioned across both system domains.

Seamless transfer between two platforms

Let’s take a closer look at the component management process. Once a new component is created in Zuken’s DS-2 from the 3DEXPERIENCE platform, all component meta data and related files from the 3DEXPERIENCE platform are transferred into Zuken DS-2. Along with it the authorization to use a component in a project context from 3DEXPERIENCE into DS-2.

Of course, this works both ways. Graphical representations of library elements such as footprints and symbols can be transferred from DS-2 into 3DEXPERIENCE in a neutral format.

For a smooth design management process, Zuken representations – native and derived – transfer seamlessly into the 3DEXPERIENCE platform for visualization, fabrication and traceability purposes. This includes the transfer of Bill-of-Material (BOM) and variant information of BOM. ECAD and MCAD data can be exchanged in different formats, such as in IDF or EDMD.

Consistency throughout the change management process

Projects and Products at a development stage are constantly evolving. Therefore, the integration places a strong emphasis on the change management process. Any modification that initiates a change in 3DEXPERIENCE will also be carried out in DS-2. The change in object status in DS-2 will be controlled from 3DEXPERIENCE. This ensures that everyone working together on a project or design to view the exact same version of data.

At Zuken and Dassault Systèmes we understand that collaboration between mechanical and electronics or electrical engineering requires integrated tools and processes.

CATIA application users and CR-8000 users can now work collaboratively on design and verification on the 3DEXPERIENCE through the dynamic integration between electronic or electrical design tools and mechanical design tools. They can rely on continuous exchange of data and configurations.

The integration creates a unified verification environment for “System Level Design,” including both electronic or electrical design and mechanical design processes. The integration of DS-2 into the Dassault Systèmes 3DEXPERIENCE platform will be marketed and maintained directly by Zuken. It will enable organizations to significantly advance their systems engineering and cross-discipline collaboration practices with consistent data.

Find out more about how you can improve your engineering and business processes at www.zuken.com/en/multi-disciplinary-collaboration/ or watch our on-demand webinar on how to get your complexity under control – with Data Management.

Related Content

- Products

Data management for PCB (DS-CR) and electrical/fluid engineering (DS-E3). DS-2 is a mature, cross-disciplinary engineering data management platform developed in partnership with more than 3,000 leading companies worldwide.

- Products

CR-8000 is a System-Level PCB & IC Package Design software including 3D Multi-board, Analysis and MCAD Integration