Variation management background

It is common for electronic product lines to share a printed circuit board assembled with different components depending on the features implemented for a specific product. For instance, a designer can use the same computer motherboard to build laptops that have more powerful or less powerful processors, different memory sizes, etc. Different targeted market regions often require different parts. For instance, power requirements and video formats vary by country. The component list for product variants is largely the same but needs to reflect the part differences for all the various products that use it.

Variation Management provides the means for the user to define the part numbers and mounting status of parts based on the product variation: delivery destination and model. Furthermore, Variant Management applications allow the user to easily switch views and export parts lists based on the destination.

Define variations and destinations

These are the steps to define the variations and destinations using DS-CR Component List Master (CLM).

1. Define each of the variations by name and the available options

2. Create destinations and assign the combination of variation options for them

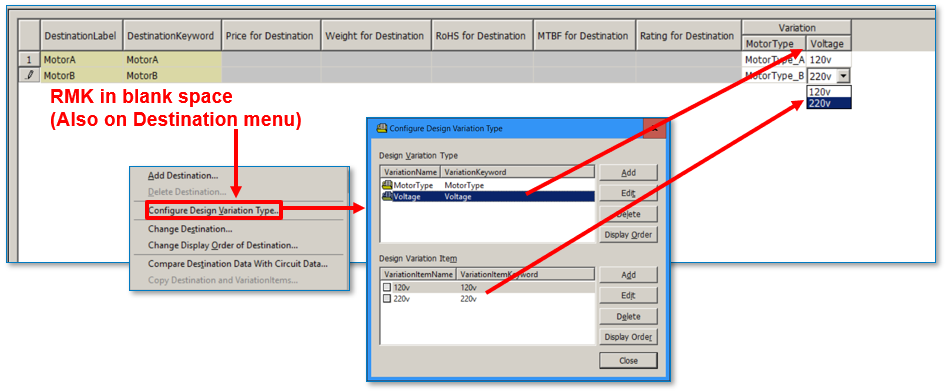

The screenshot below shows how to define variations and destinations for a product with a motor driver circuit motors with different power ratings.

When a destination is added, its name is added to the list, and then the user selects the suitable variation values for it.

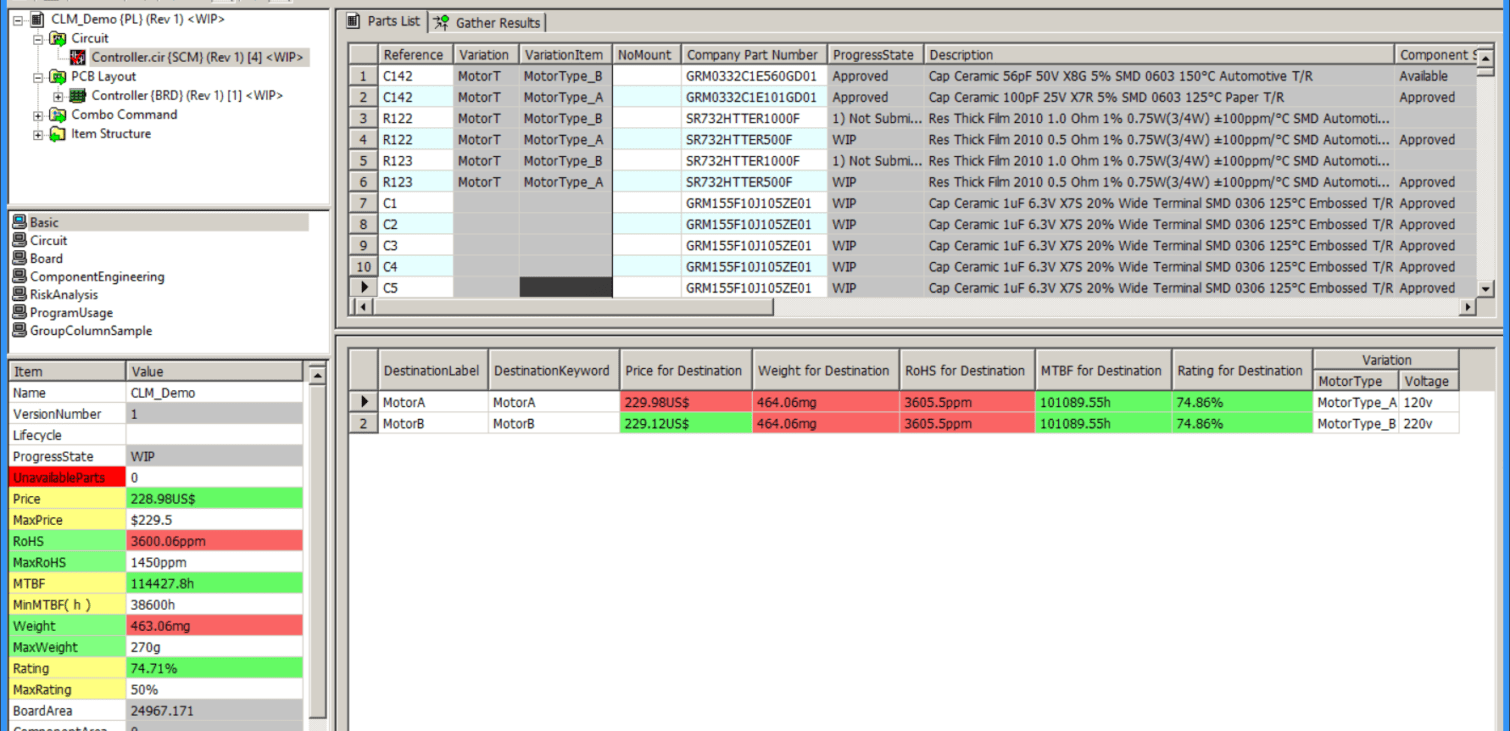

Assign variants to the component list

Parts that vary by model or destination are assigned a variation. Each variant has a unique row on the components list that contains its part number. A No Mount setting is used in case the part is not used for that variant.

This video shows how to add assembly variations to a component list in the DS-CR Component List Master application.

One Comment