This two-part post explores the top features of E3.series 2021. The new features fall into four broad categories:

- Productivity and user experience

- Library creation and administration

- Connector automation and harness design

- Wire visualization and cabinet design

Part 1 of the series outlines improvement in user experience, library creation process, and library administration. You can find the first part of the blog here:

The new release’s fundamental goal is to create an ecosystem to foster multi-disciplinary cooperation and enable a digital engineering workflow. The Smart Cabinet Building initiative and enhancements to library development with Component Cloud for E3.series are vital steps towards realizing a connected engineering workflow. In addition, the E3.series 2021 release is pushing the envelope to drive advancements in design and manufacturing technologies.

Part 2 of What’s New in E3.series 2021 details the improvements in connector handling, harness design, wire visualization, and cabinet design. There is something for all users in the 2021 release of E3.series. Right from systems design to harness manufacturing to cabinet design. At Zuken, customer requests, needs, goals, and aspirations drive the development process.

I’ll pick up where I left off in Part 1 with the third category . . .

3. Connector and harness design in E3.series 2021

E3.series 2021 improves connector handling and harness design with automated quality and error checking options. Cables and harnesses are integral parts of all electrical designs, and connectors are inevitable parts of a harness. Therefore, efficiently managing them drastically improves overall efficiency. In 2021, E3.series builds on its solid foundational elements to supercharge the design process.

Manual connector plugging check

E3.series automatically runs live checks on connector assignments, symbols, and compatibility during the design process. As a result, more errors are caught and eliminated at the source instead of after the design is complete. However, in previous instances, users manually plugging connectors could override some of these checks. For instance, it was possible to force plug incompatible connectors. Now, even manual plugging of connectors is subject to additional design rule checks (DRCs). The new DRCs are active only if enabled in E3.series project settings.

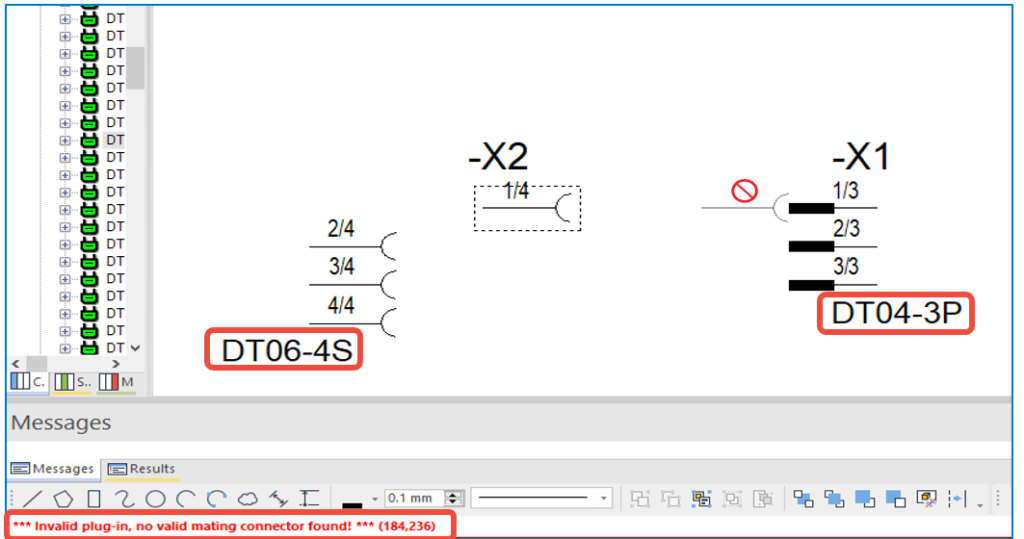

Valid mating connectors

The first DRC prevents connections between invalid mating connectors. The new error check cross-checks the connector information from the parts library. Upon finding an invalid mating connector, the application stops the error and informs the user of corrective action. For instance, a connection between a four-pin connector and a three-pin connector is invalid. Additionally, the same DRC applies for changing parts on existing connections and drawings.

Pin gender definition

In E3.series 2021, the database definition of ‘pin gender’ for connector pins is available on all connectors. Previously, the definition only existed for MIL connectors. The introduction of additional pin gender definition opens the door for new DRCs. The new setting in the E3.series project enables the DRC to confirm the pin gender before connecting. As a result, it is not possible to plug two male connectors or two female connectors to establish a valid connection. Notably, the default value for connectors is ‘no entry’, which leaves the door open to manage exceptions.

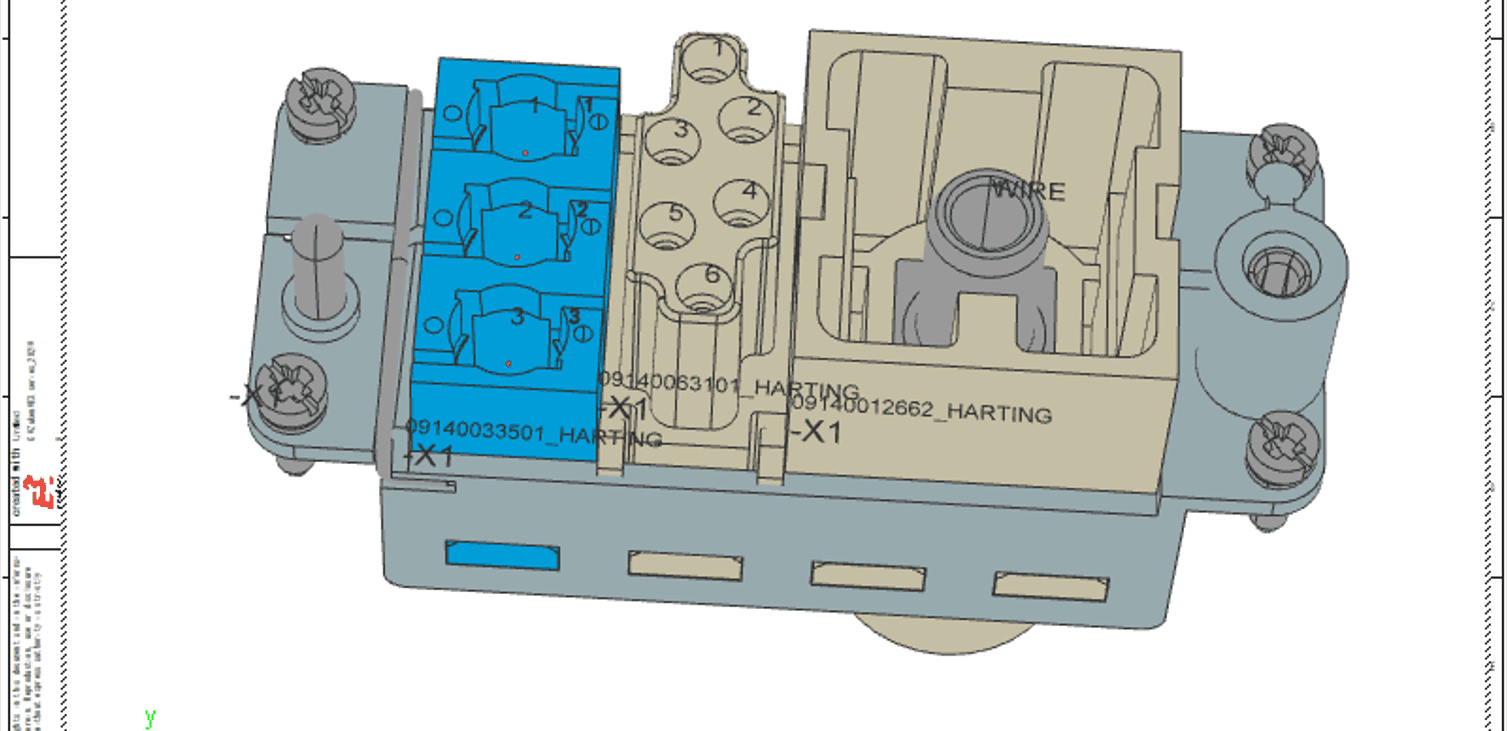

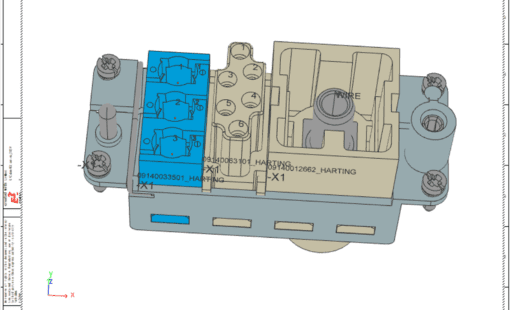

Connector with inserts

E3.series expertly handles complex connectors with multiple configuration options. In E3.series 2021, the possibilities for managing these complex configurations is expanding to accommodate even more variations. It is now possible to define empty slots in the connector housing. As a result, connector variations requiring two slots are easily configurable. Importantly, even though the slot is predefined in the library, a case-by-case manual modification feature is available in the project.

MCAD and ECAD integration with E3.3DTransformer

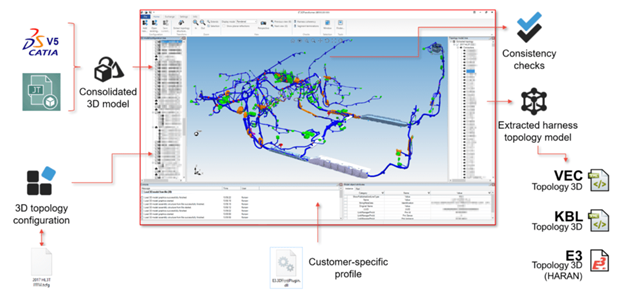

The mechanical design and packaging have a significant impact on a harness. The aspiration of collaborating with mechanical design to create an accurate functional harness with the least effort is common across teams. E3.series supports various MCAD tools and strives to create a streamlined process to transition the mechanical model as a reference for the harness design. However, the process differs with every MCAD solution provider. Consequently, Zuken creates a seamless solution to work with native MCAD files in an electrical design-friendly environment to drive harness detail extraction.

The E3.3DTransformer is a new add-on tool to take 3D files from MCAD systems to drive the harness design process in E3.series. The current integration with MCAD for the harness design in E3.series uses the E3.3DRoutingBridge. The routing bridge process works well for harness designs when a topological XML list or flattened structure is readily available. Typically, extracting 3D geometry and topology from these mechanical platforms for harness manufacturing details is painstaking. The existing workflow uses 3rd party tools to flatten the 3D geometry from the mechanical design. Additionally, a harness flattening process can lose essential information like location or types of grommets and fixings.

E3.3DTransformer easily and quickly extracts harness information from MCAD systems to use in E3.formboard. The updated application support major platforms including CATIA V5, JT files created by Siemens PLM BX, XML and files exported from SolidWorks. E3.3DTransformer, with its rules-based engine, quickly extracts topology, fixings, and other information from native 3D mechanical files saving time and reducing errors.

4. Wire visualization and cabinet design in E3.series 2021

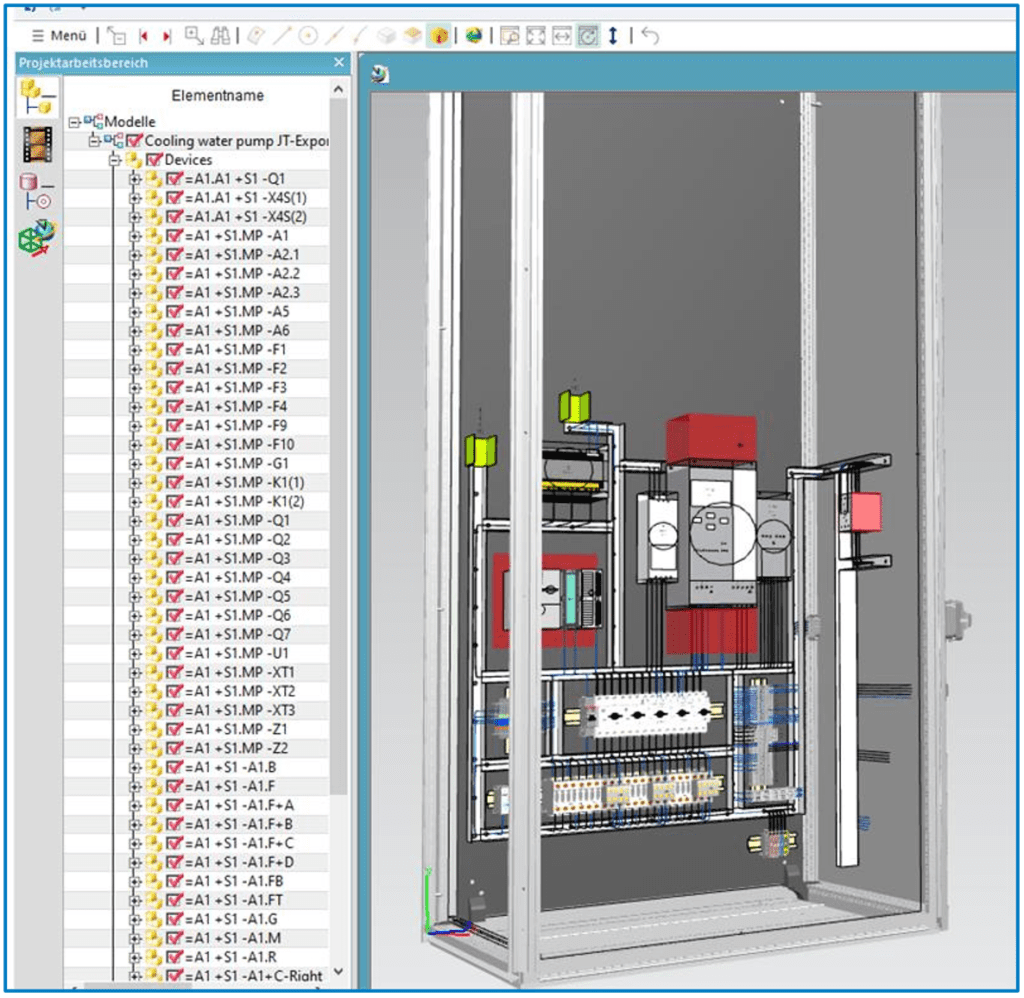

The need for electrical cabinets, or panels, is growing faster than ever, driven mainly by the overall electrification trend in almost all industries. Cabinets are typical in many industry verticals like power distribution, safety systems, industrial controls systems, automation, machinery, and many more. As a result, there is considerable variation in size, complexity, and even design practices.

The E3.panel application empowers users to create detailed cabinet designs. The designs include schematic-driven cabinet layouts with the option to route wires automatically. The feature that sets E3.series apart is the ability to design in a 2D environment and affect the result in 3D. Significantly, E3.panel is available simultaneously in a 2D and 3D design space.

In E3.series 2021, updates are available for 2D design, 3D visualization, and 2D-3D visualization of the wire routing in the cabinet.

2D views

In addition to creating multiple 2D reference views of a mounting surface, managing views is easier than ever. The management and creation of 2D views have new options in sheet properties to control projected views individually. The controls for location and scaling of the 2D views on a drawing sheet are now available in the sheet properties.

Automatic 3D pivoting

The designer defines the orientation of devices in the cabinet at the time of placement. Previously, moving a device from one side of a 3D cabinet to the other required a manual pivot to ensure proper orientation. In E3.series 2021, the device moved from one view to the other, automatically oriented in the default orientation in that view. For instance, moving a device from the left wall of the cabinet to the right wall automatically orients the device to fit accurately.

Intelligent device placement in panel

Dragging and dropping multiple items on mounting surfaces is one of the favorite panel design features in E3.series. Numerous models are placed automatically and mated to the mounting surfaces. Auto-correction and collision avoidance are active during the active placement routine.

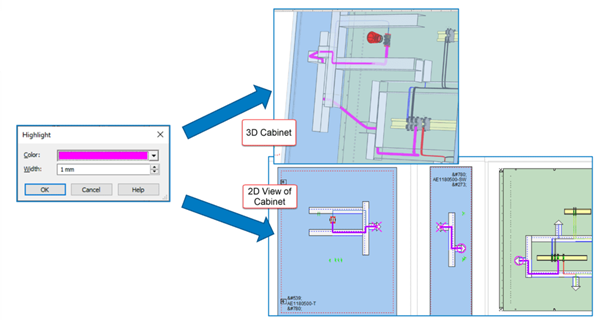

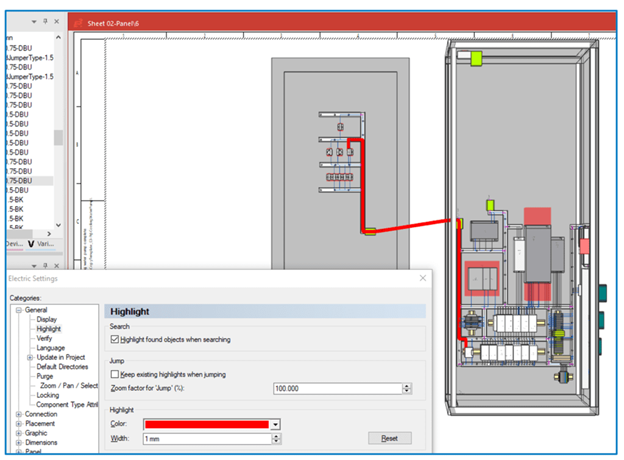

3D wire highlight

E3.series 2021 introduces new and exciting visualization options for a wire in 3D. Now, the wires in 3D are highlighted using the same settings as other highlight options in E3.series. As a result, wires are clearly visible even in cabinets with many overlapping wires routed through the same channel. Most importantly, the wire route is visible in 3D even when wires pass through distributed wiring ducts.

New highlight panel path

The new command ‘Highlight panel path’ improves the wire visualization process by highlighting the wire in all views where the wire is displayed. The command highlights the wire in 2D, and 3D views. Notably, if closed, the sheets are opened automatically to highlight the path. In addition, the wire highlight color and width selection option simplify the highlight process. The wire highlighting persists even when highlighting subsequent wires. As a result, selecting different wire colors on each highlight improves the wire path visibility. The wire highlight colors are visible in the device tree. The right-click context menu provides the option to reset the panel path highlights.

Duct fill ratio

The visualization of the wire is a direct result of the robust routing function in E3.series. Cable ducts play a crucial role in managing valid routes in a cabinet design. In E3.series 2021, the duct fill ratio is adjustable at multiple levels. The adjustments are available at the project level and on individual ducts. In addition, a separate warning limit option provides timely notifications. For instance, set ducts in strategic areas to a lower fill limit for future expansion. In contrast, a higher limitation for ducts in high-density areas with standard wiring improves operation efficiency.

Export 3D data in JT format

Communicating 3D data to and from mechanical design tools is vital for a digital engineering workflow. In E3.series 2021, 3D cabinet information is exported in JT format in addition to the STEP format. JT is a standard format supported by most major MCAD applications. Unlike the STEP models from E3.series, the JT export contains details about all devices, mounting plates, ducts, wires, and more. The JT format export is only available in the 64bit version of E3.series 2021.

More information

ZIW Europe digital 2021 was a smashing success. Though the live broadcast is over, you can still view some of the sessions on-demand on our website.

The E3.series 2021 release contains many features and enhancements to help users improve their design process. A comprehensive list of new features is available within the application. Find more about the top features on our website.

- Press Release

E3.series 2021 from Zuken delivers enhancements for connector handling, 3D control cabinet design and ECAD/MCAD collaboration.

- Software Evaluation

E3.series Test-Drive provides a web-based training course that guides you through the creation of a real life design example with E3.series using E3.cable and E3.panel