Digital recording and documentation of the testing of wiring and electrical equipment

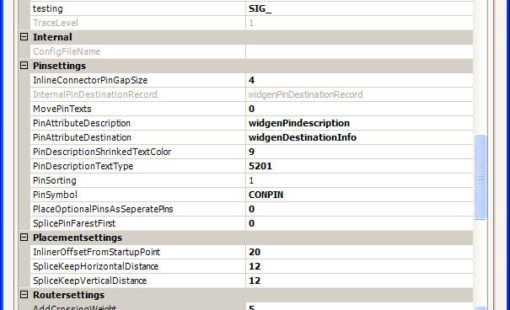

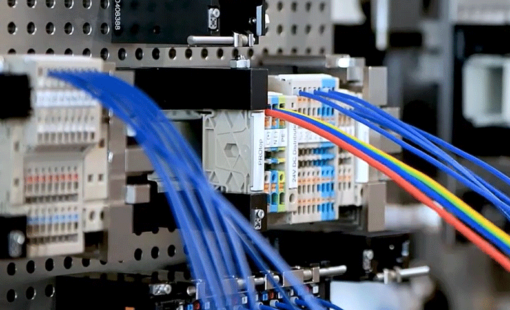

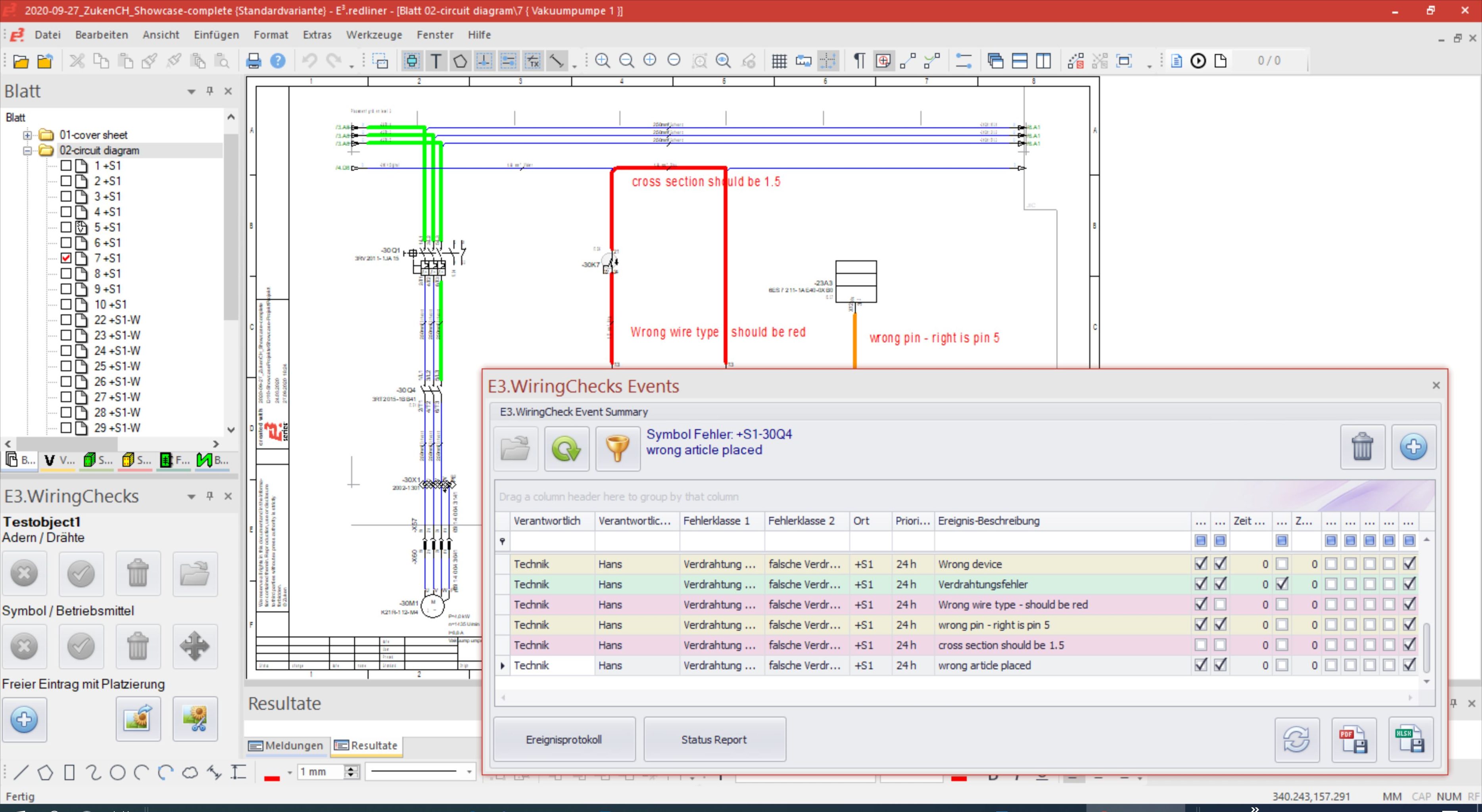

E3.WiringChecks supports the electrical start-up testing of a fully wired machine, vehicle or control cabinet before or during the commissioning phase. Results can be documented as part of the E3 data record. The error descriptions can be accessed by all relevant departments from engineering to production and assigned issues can be accessed and processed. In this way, error correction and follow-up checks can be carried out in a controlled process.

Digital recording and documentation of the testing of wiring and electrical equipment

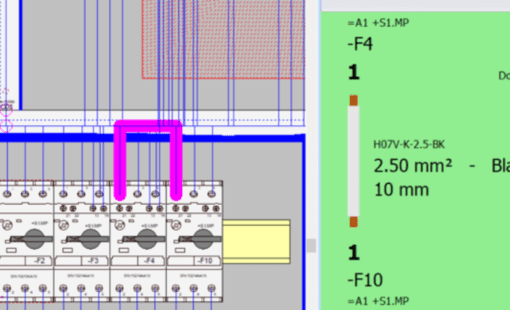

Capture and description of errors and documentation within the circuit diagram

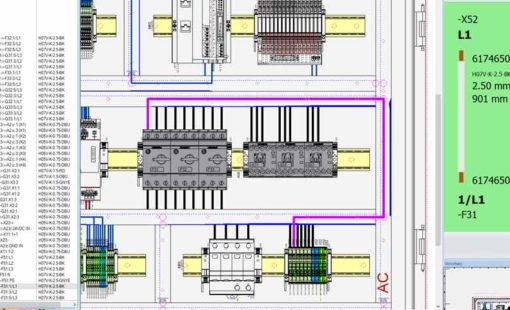

Documentation of the testing results as part of an E3.series project

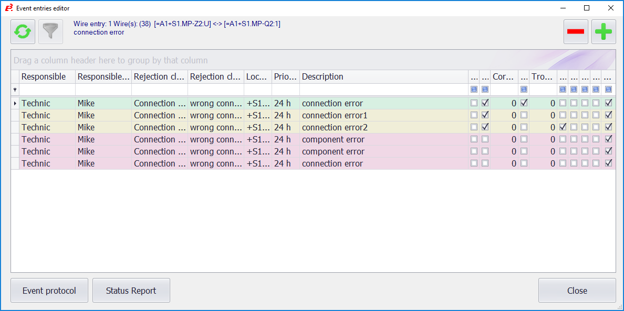

Electrical start-up testing of wires and devices is digitally recorded and marked as checked or fault error. In the event of an error, an incident can be recorded, described, and placed at the appropriate position in the schematic. The error descriptions can be accessed by all relevant departments, from engineering to production, and the events assigned to them can be called up and processed. In this way, it is ensured at all times that error correction and subsequent checks can be processed in a targeted manner.

The error descriptions can be accessed by all relevant departments, from engineering to production, and the events assigned to them can be called up and processed. In this way, it is ensured at all times that error correction and subsequent check can be processed in a targeted manner.

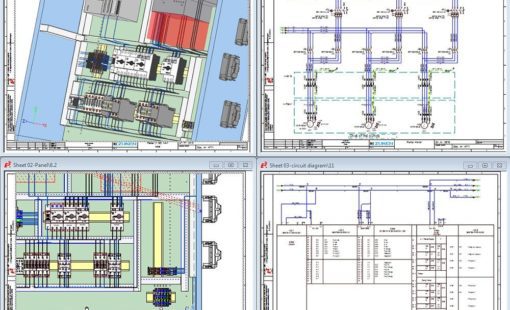

Digital Manufacturing with E3.series

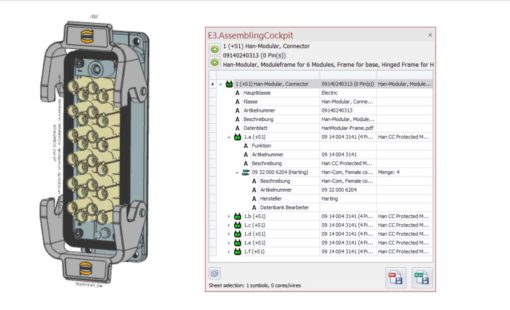

E3.AssemblingCockpit helps workers in the assembly department to select and assemble the individual parts for modular connector assemblies and other components that have to be assembled from comprehensive parts kits.

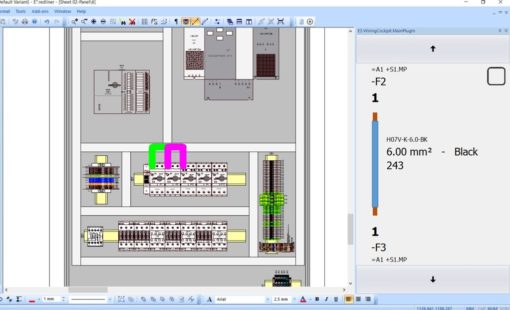

E3.WiringCockpit enables the display of wiring paths and connection information on mobile devices.

E3.WiringDiagramGenerator automatically generates schematics or wiring diagrams for development, service, and after-sales.

E3.panel allows engineers to layout components inside panel enclosures in both 3D and 2D. Intelligent automatic snapping points allow parts to be easily placed in their correct location.

Weidmüller, Komax, Zuken, nVent Hoffman / Steinhauer and Armbruster Engineering launch the SMART CABINET BUILDING initiative

This webinar will provide details and demonstrations of the various tools available to help support the manufacturing automation of cabinet / panel designs.

In this webinar we will demonstrate the possibilities of E3.WiringChecks based on a concrete and consistent application example.

E3.AssemblingCockpit, E3.WiringCockpit and E3.WiringChecks provide operators on the shop floor with all information required for assembling, wiring, and start-up checks in a paperless form via portable terminals.

Paperless engineering improves accuracy, traceability, and schedule. Communication gaps riddle engineering companies, and E3.series tools E3.WiringChecks and E3.WiringCockpit is here to facilitate communication between design, checking, commissioning, technicians, and all parties involved after the initial design.

An immature design or manufacturing process leads to excess complexity. Smart manufacturing options driven by intelligent design solutions provide a repeatable and efficient path to simplify manufacturing processes.

Communication between disciplines is increasingly critical as complex designs require more and more collaboration. Communication gaps often riddle engineering companies. E3.WiringChecks and E3.WiringCockpit is here to facilitate communication between design, checking, commissioning, technicians, and all parties involved after the initial design.

A drawing on paper remains evidently two dimensional with little to no room for improvement. A PDF is a step up with the ability to pack a few layers of data but without the ability to have detailed instructions to drive manufacturing excellence.