Consistency of all design phases through object orientation

Zuken E3.series offers powerful options and variant management to create and manage design configurations for a wide range of vehicles. Easily manage 150% representations of designs by quickly activating or deactivating the desired circuits.

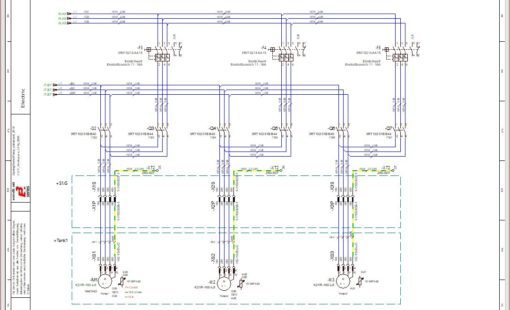

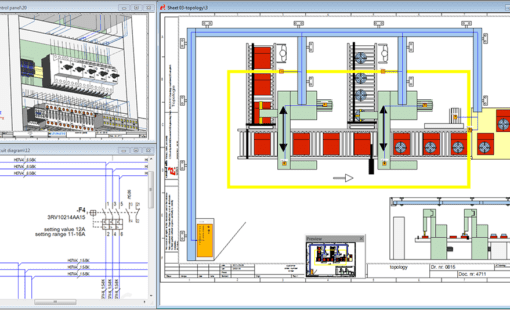

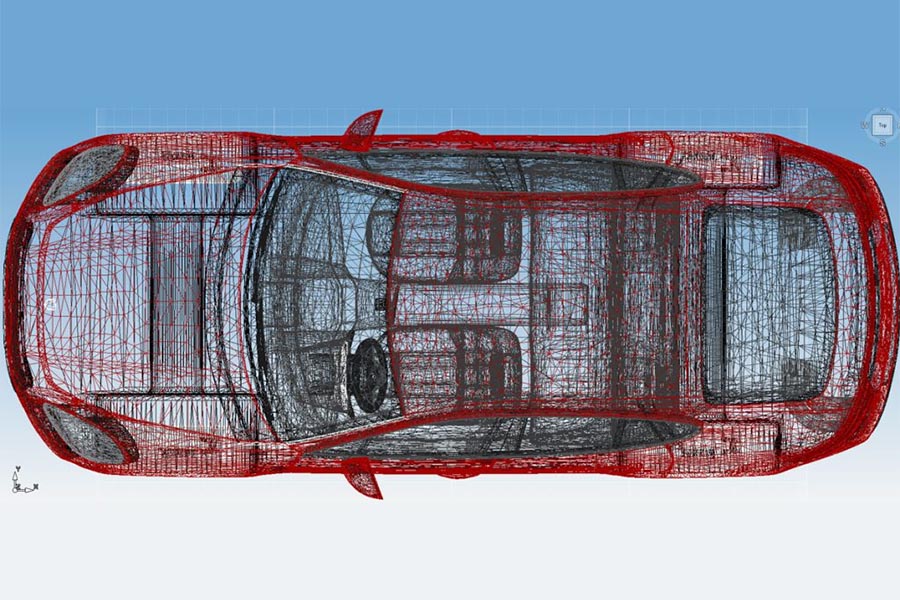

The Collaboration between E3.series and MCAD tools facilitates concurrent engineering. E3.topology takes logical designs into the physical world. Signals, wires and cables between installation areas can be routed automatically. The integrated design rules check engine prevents errors, increases productivity and improves accuracy for manufacturing.

Consistency of all design phases through object orientation

Powerful automated operations and electrical checks

Comprehensive outputs for manufacturing and documentation

Native format library and design data management

E3.series Features & Solutions

More than a CAD Tool

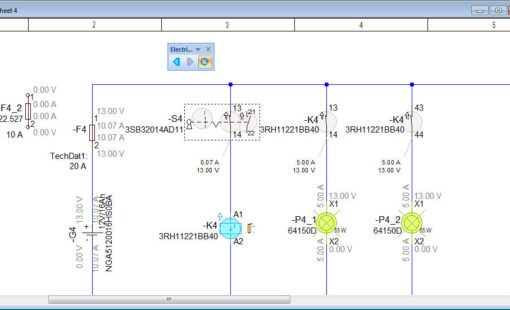

E3.schematic is the core module of the E3.series suite that enables the creation of schematic diagrams for electrical control systems.

E3.topolgy is a tool that allows sheets to represent the chassis of a vehicle, installation spaces such as the dashboard or control panels are easily added to the sheets. The connections between these installation spaces represent harness routes or cable trays.

Alternate views of logical devices are held in the same project and placed into the relevant installation spaces.

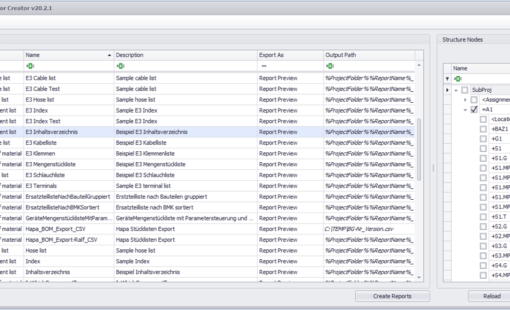

E3.ReportGenerator is a tool for creating customized reports from E3.series projects in simple steps. These reports can be configured according to various parameters and exported in different formats.

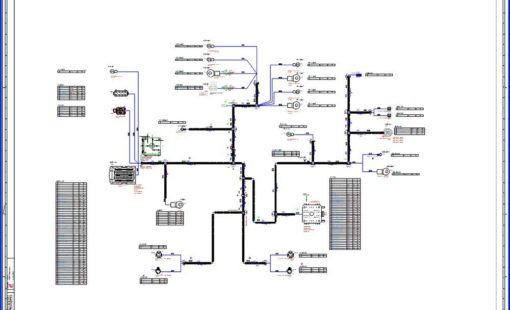

E3.formboard is a complete solution for creating cable harness drawings for manufacturing automotive vehicles. Different sheet sizes are available for use in manufacturing. Automatic functionality makes the placement, arrangement, and dimensioning of the harness and its segments easier.

E3.formboard is integrated with E3.cable. The logical interconnection data defined in E3.cable is used directly in E3.formboard, and any changes made in either module are automatically updated.

The Component Cloud for E3.series complements its database. The libraries are provided directly by the manufacturers of the respective electronic components.

Components and symbols can be created with all additional parts, for example, terminals and seals. Also, defining signals to all error-free ‘drag and drop functionality.

E3.Revision Management ensures all changes are tracked and documented. Alternative revisions of designs are compared and checked against each other, and any changes are reported and stored in both graphical and textual formats.

Automotive Case Studies

Engineers working on new designs or updating current systems rely on correct, reusable data and information. An Intelligent component-based parts library that ensures only up-to-date parts are available helps drive the design with automatic part selections and simple ‘drag-and-drop’ functionality.

Objects such as power sources, fuses, switches, complex devices, and loads require simulation to facilitate functional testing. Switches and contacts within the design are controlled by the voltage and current passing through the circuit, simulating real-life operation. As current passes through to the load, the voltage of objects such as lamps or motors can be checked and success or failure information is fed back to the user.

Learn More

E3.series enables the creation of a digital twin by seamlessly synchronizing data between ECAD, MCAD and other enterprise IT systems. The versatile workflow in E3.series helps design teams work independently or collaboratively to meet project requirements.

Electrical engineers can collaborate with mechanical design through a bidirectional interface between MCAD and ECAD. Flattening options simplify the use of a 3D harness model to create formboard drawings for manufacturing.

Learn More

Topology optimization is used for achieving predetermined performance goals and obtaining the best layout for vehicle wiring harnesses. In the early phases of design, the level of detail is low while the design freedom is high. By introducing a tool to support the early vehicle harness design, the potential of finding a more efficient layout increases.

A topology-specific tool will improve the design process by exploring different approaches in the early design stage to determine the best solution. Tools can be used to predefine routing criteria for signals and power sources to assist in correct wire routings.

Learn More

Wire harness designers require 1:1 wire harness layout drawings that include connection tables, clips, heat shrink, and convoluted tubes. The ability to automatically determine wire lengths and calculate the outside diameter of the harness segments and branches speeds up design processes. Automatic connector view selection, and correct terminal selection, including associated items like seals, back shells, and blanking plugs, are necessary to reduce time and costs and allow a right-first-time approach.

The automatic generation of reports, such as bills of materials, helps reduce the workload of mundane tasks, automates the process, and empowers designers to get on with designing.

Learn more

Intelligent design data and accurate capture of design intent are the foundation for unlocking the benefits of digitally augmented assembly processes. Automated reporting and documentation options simplify the product assembly and service.

The always up-to-date design data ensures consistency and quality across the assembly process. Automatic terminal configuration, labeling information, cut-out, layout and keep-out area marking, and other vital characteristics of the design software eliminate many manual error-prone processes.

Learn more

Automatic generation of estimates, quotes, bills of materials, wire lists, and many more reports to drive upstream and downstream processes is the best practice today. Reports can be used for costing purposes or by manufacturing teams for bills of materials.

Intelligent report generation tools help users create customizable reporting templates. Reports exported directly to leading PLM and PDM solutions create a seamless data transfer between departments.

Learn more

E3.series helps to accelerate the time-consuming creation of work instructions for the wire harness building process by using engineering data to create, release and manage work instruction packages. The creation process utilizes the in-depth manufacturing data captured in E3.series projects during the design phase.

Pre-built customizable work instruction templates ensure consistency across projects. Auto-actions trigger repeatable custom automation routines to assemble relevant assembly instructions. The combination of accurate design data and configurable reports improves quality control and increases productivity.

Learn more

Related Products

The E3.ReportGenerator is a free tool for creating customised reports from E3.series projects in a few simple steps. These reports can be configured according to various parameters and exported in various formats. The tool requires no licence and can be launched directly from within E3.series.

E3.eCheck is an extension to E3.series that enables users to functionally analyze their electrical schematic circuits and check designs for fuse and wire sizing errors.