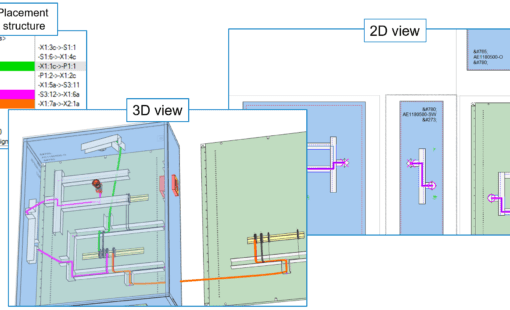

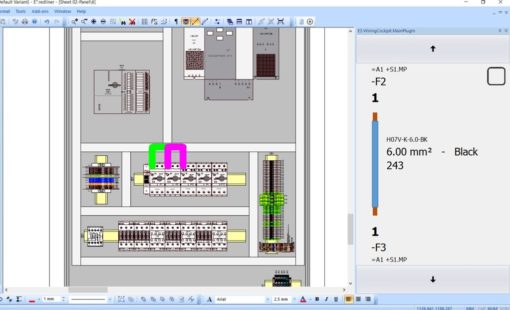

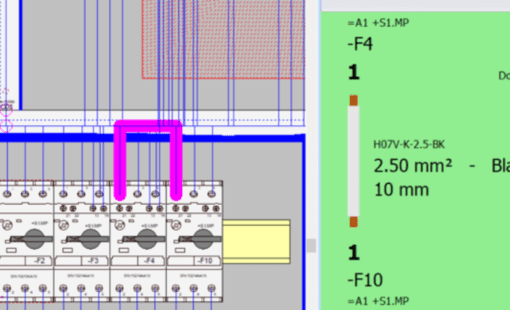

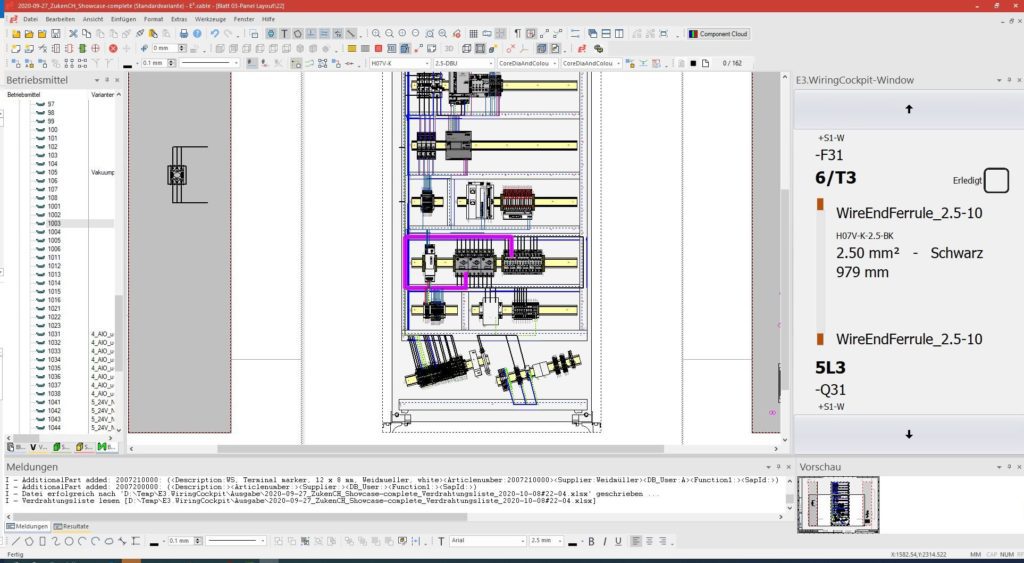

Highlights the wiring paths

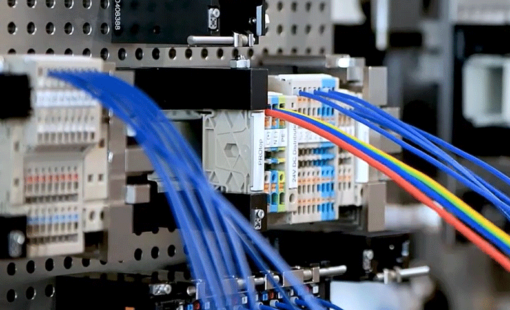

E3.WiringCockpit improves communication between design and installation technicians. It displays wire-by-wire work instructions in a simple user interface. This results in quantifiable benefits of faster cycle times and improved build accuracy.

Highlights the wiring paths

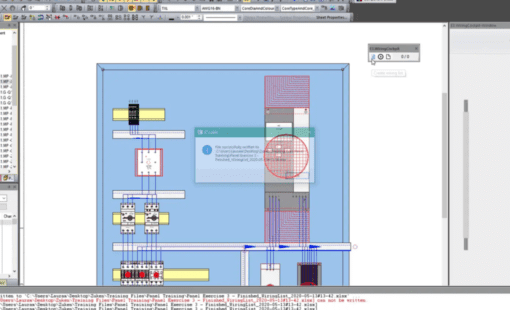

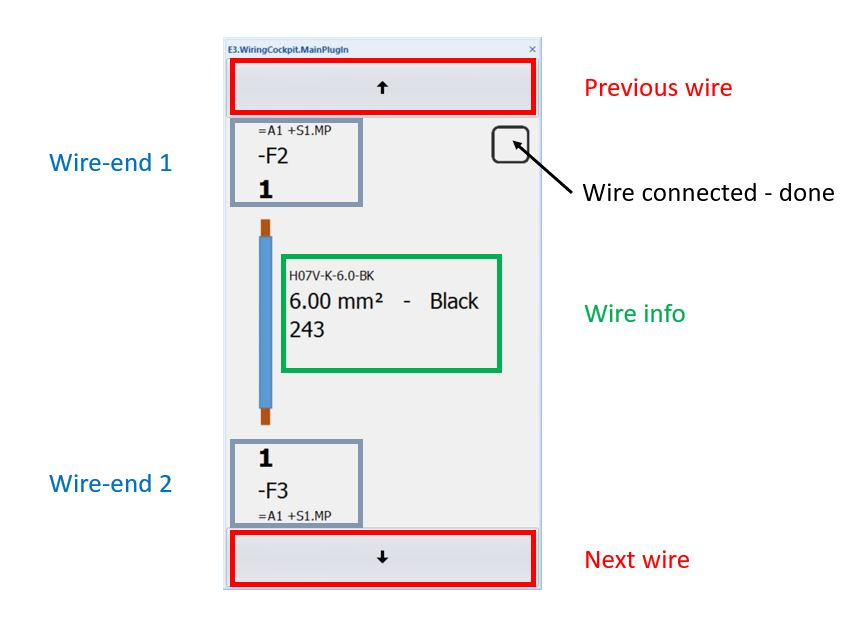

Confirm and proceed to next

Logging of the wiring progress

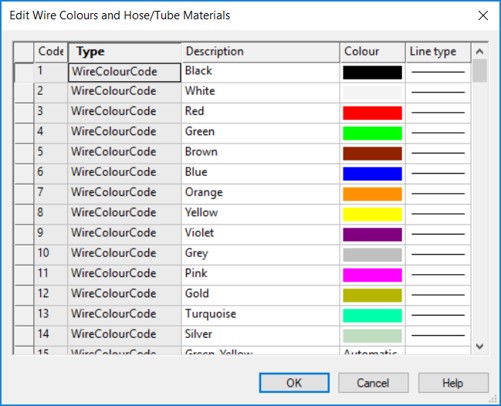

E3.WiringCockpit highlights the wiring paths in the digital control cabinet wiring layout and displays all additional information relevant for the user. After the user has confirmed the completion of a connection, the next wire is displayed.

The wiring sequence can be determined and optimized using an Excel export. The optimized wiring sequence helps the operator to wire the cabinet in a very efficient way.

After the user confirms the processing, the next wire from the wiring list is displayed. The progress of the wiring is logged so that work can be continued at the exact same point in the event of an interruption.

Related Products and Solutions

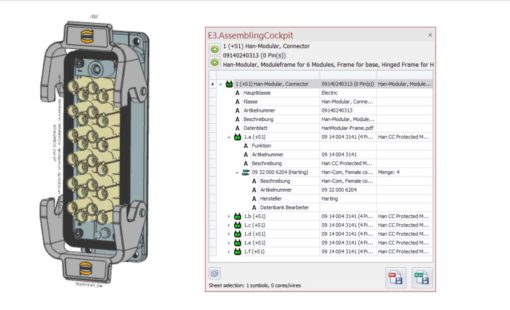

E3.AssemblingCockpit helps workers in the assembly department to select and assemble the individual parts for modular connector assemblies and other components that have to be assembled from comprehensive parts kits.

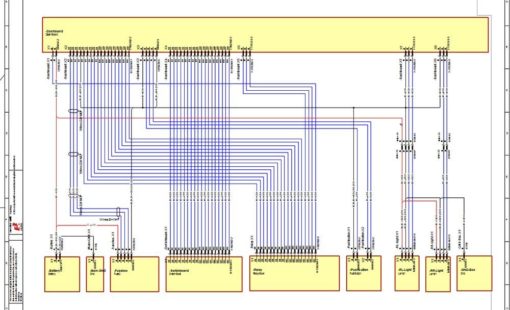

E3.cable extends the functionality of E3.schematic enabling individual conductors to be combined together in the design to form cables and harnesses.

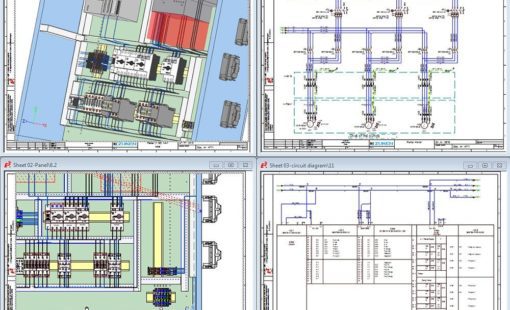

E3.panel allows engineers to layout components inside panel enclosures in both 3D and 2D. Intelligent automatic snapping points allow parts to be easily placed in their correct location.

Weidmüller, Komax, Zuken, nVent Hoffman / Steinhauer and Armbruster Engineering launch the SMART CABINET BUILDING initiative

Related Resources

In this Smart Cabinet Building webinar, we will present you a selection of new functions of the E3.series 2022 release. This session concerns enhancements in E3.panel, as well as the tools for manufacturing automation, in particular E3.CutOut, E3.ExportToKomax and E3.WiringCockpit.

This webinar will provide details and demonstrations of the various tools available to help support the manufacturing automation of cabinet / panel designs.

E3.AssemblingCockpit, E3.WiringCockpit and E3.WiringChecks provide operators on the shop floor with all information required for assembling, wiring, and start-up checks in a paperless form via portable terminals.

Paperless engineering improves accuracy, traceability, and schedule. Communication gaps riddle engineering companies, and E3.series tools E3.WiringChecks and E3.WiringCockpit is here to facilitate communication between design, checking, commissioning, technicians, and all parties involved after the initial design.

Recent E3.WiringCockpit Blog Posts

Companies are to expect an acute shortage of qualified workers in the coming years. We will show levers for optimizing workflows and tools in production so that you can adapt your processes to meet the challenges of the lack of specialists in control cabinet building.

Due to the pandemic, the annual SPS automation trade fair will not take place physically. However, there will be an online-alternative: the SPS Connect, starting on the same day.

An immature design or manufacturing process leads to excess complexity. Smart manufacturing options driven by intelligent design solutions provide a repeatable and efficient path to simplify manufacturing processes.

E3.WiringCockpit is a great Cabinet Production tool to use alongside with E3.series. Making it easier to connect between engineering and manufacturing...

Communication between disciplines is increasingly critical as complex designs require more and more collaboration. Communication gaps often riddle engineering companies. E3.WiringChecks and E3.WiringCockpit is here to facilitate communication between design, checking, commissioning, technicians, and all parties involved after the initial design.