Consistency of all design phases through object orientation

Zuken’s E3.series is a leading single-platform solution to take a design from concept to manufacture. With enhanced busbar handling and cabinet visualization in 3D and 2D, E3.series empowers engineers to design control cabinets, panels, and cabling systems for a wide range of industrial machinery. It encompasses detailed schematics, wiring, and complete manufacturing documentation.

E3.series transforms product development with electrical data management solutions seamlessly connecting to existing PLM and PDM systems. Documentation according to common standards such as IEC 81346 and IEC 61355 enables engineers to create modular projects.

Consistency of all design phases through object orientation

Powerful automated operations and electrical checks

Comprehensive outputs for manufacturing and documentation

Native format library and design data management

More than a CAD Tool

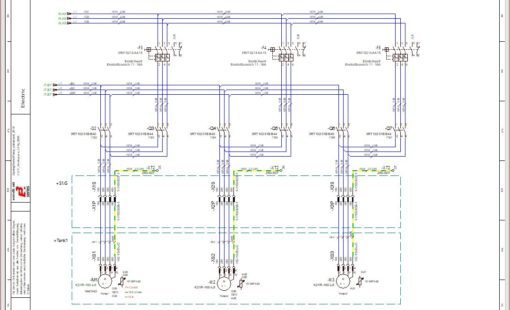

E3.schematic is the core module of the E3.series suite that enables the creation of schematic diagrams for electrical control systems.

E3.cable is used to design and document cable plans and cable harness drawings. E3.cable is an extension of E3.schematic to combine individual wires into multicores or cable bundles, add shielding and twisted pair structures to the multicores, and automatically display them in the schematic.

Complete systems and subsystems such as control units, rack equipment, or even black boxes can be replicated as functional blocks in a hierarchical design.

The E3.ReportGenerator is a tool for creating customized reports from E3.series projects in a few simple steps. These reports can be configured according to various parameters and exported in various formats.

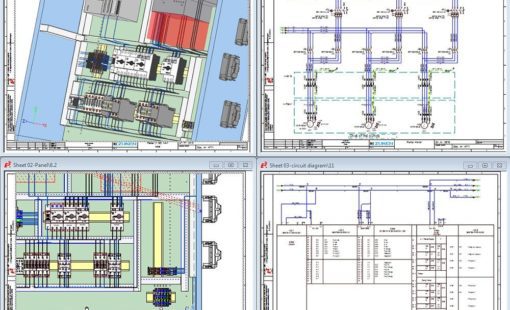

E3.panel enables engineers to layout components within control cabinets in both 2D and 3D. The signal logic is used directly from the E3.schematic circuit diagram.

Wires can be routed automatically through the control cabinet using an auto-routing function.

E3.panel provides an integrated engineering solution for advanced control cabinet engineering. By linking to wire processing machines, wires can be automatically stripped, crimped, and marked.

E3.component cloud compliments the E3.schematic database. Component libraries are provided directly by the manufacturers of the respective electronic components.

Components and symbols can be created within E3.series with all associated parts, terminals, and seals. Also, pre-defined signals can be used to allow error-free drag-and-drop functionality when designing.

E3.Revision Management ensures all changes are tracked and documented automatically. Alternative revisions of your designs are compared against each other and any changes are reported and stored in both graphical and textual formats.

Case Studies

The start-up company INORCOAT relies on Zuken’s E3.series for the development of environmentally friendly nanotechnology coating systems. INORCOAT’s first system was recently put into operation at the Portuguese National Bank for the coating of dies for euro coins.

Hydro-Québec simplified design process for power distribution network substations by implementing Zuken’s E3.series

Kellenberger develops and produces numerically-controlled precision grinding machines and systems for sectors such as automotive, medical devices and industrial machinery. The Swiss-based manufacturer recently introduced Zuken’s E3.series to automate the generation of schematics for customer-specific machine configurations, cutting the time taken by more than 90%.

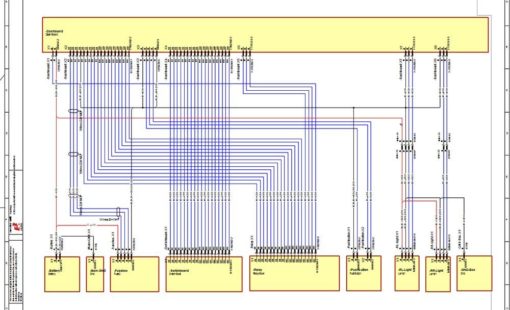

Engineers working on new designs or updating current systems rely on correct, reusable data and information. The intelligent component-based parts library that ensures only real-updated parts are available to help drive the design. Automatic part selections and pre-defined signals would allow simple and quick drag-and-drop functionality would be an advantage.

Signals are routed following user-defined criteria after placement of components, by wiring, or by signal information. Connection patterns are maintained and updated whenever a component position is modified would be a must.

Learn more

Cabinet design engineers design the layout of components inside panel enclosures. Designers can create designs in both 3D and 2D with intelligent automatic snapping points that allow parts to be placed easily in their correct location.

The ability to prevent clashes and keep-out and height restrictions would lead to a massive improvement.

The ability to navigate between the panel and schematic and changes to either are displayed immediately. This functionality ensures that all views of the design are correct and up to date.

Learn more

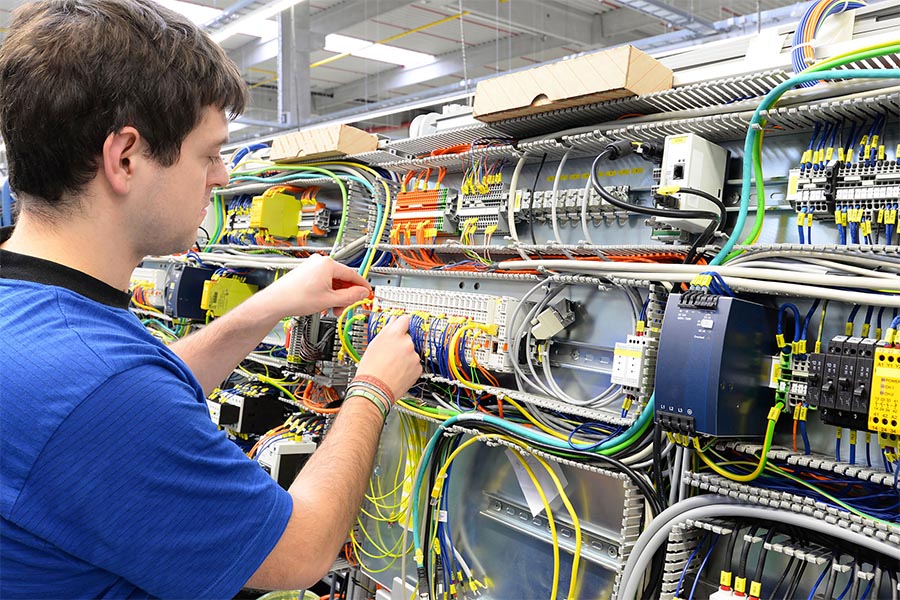

Wiring is a common challenge of traditional cabinet design. Designers of wiring must consider wiring duct space, current chains, wire size, and logical connectivity when calculating routes.

E3.series checks duct fill capacity for wires and reroutes as required to ensure wiring standards are maintained would be of great benefit.

It uses an advanced algorithm with configurable options to ensure consistent wiring to match the requirements of a diverse range of cabinet applications. The 1:1 scale designs provide accurate wire lengths and wire termination details to feed cutting-edge automated manufacturing processes.

Learn more

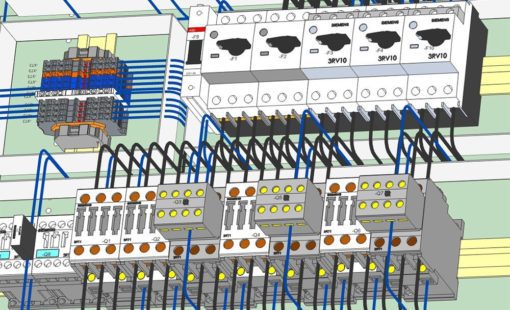

Production assembly requires accurate wire lengths and termination information to enable manufacturing automation. Digital data from E3.series can drive highly automated wire-cutting and processing machines. The result can lead to a reduction in process times.

Connecting devices for labeling, marking and other printing options for wires can be automated and therefore reduce the possibility of errors in manufacture.

A requirement to produce clear assembly instructions and automation options with configurable reporting would help extract engineering data to utilize the latest automation technologies.

The ability to define 3D data with detailed mounting parameters, clearance requirements, and space allocation assists design teams in creating accurate cabinet layouts.

Learn more

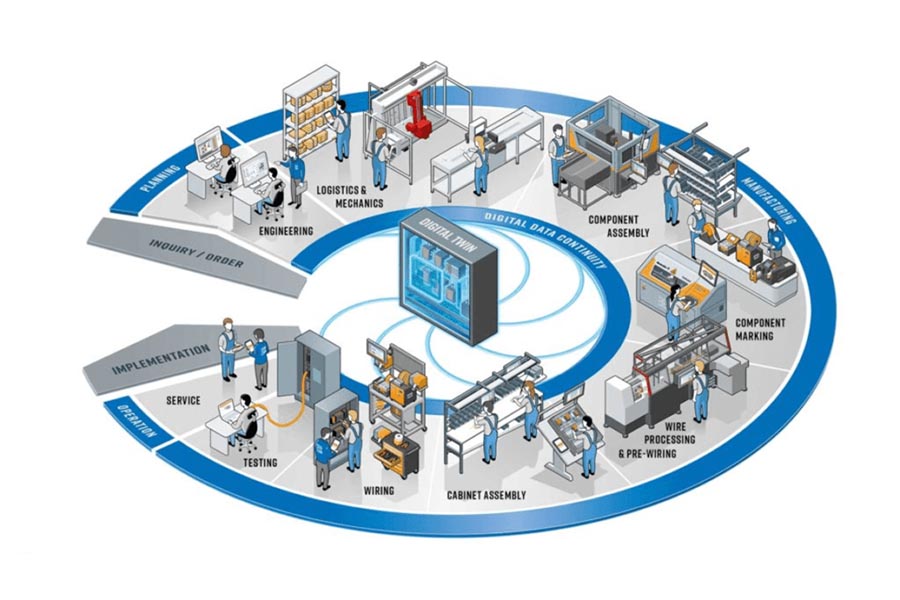

Digitalization offers many options for the optimization of production processes. However, overall productivity will only increase if consideration of individual value-added processes is addressed.

E3.series and our Smart Cabinet Building partners can provide a comprehensive turn-key solution for todays and future challenges in control cabinet manufacture. Networking technology leaders in different areas of electrical cabinet building and pooling their expertise and know-how across all process stages.

Learn more

Engineers require exact mounting and cut-out information to allow production to drive automated drilling and milling machines. Accurate 3D data from STEP models and detailed mounting descriptions would help users create high-quality cabinet layouts. Design rule checks would help validate the cabinet design’s form, fit, and function.

With intelligent design data being available to drive downstream manufacturing and assembly automation, connect to leading intelligent cabinet manufacturing machines.

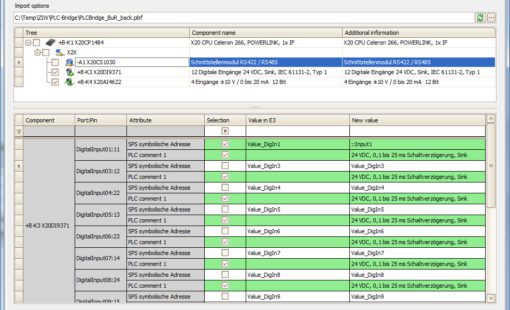

With the ability to connect production machines via a PLC configuration solution, manufacturers can streamline their digital workflow.

Learn more

The requirement of automated B.O.Ms and wire lists to help with precise parts data is a must. A library, a single source project with logical and physical connectivity, and accurate wire lengths create an intelligent design process automating wire, wire termination, and peripheral device selections.

Reporting options facilitate multiple reporting formats and configurations to enable, for instance, easy to switch between representing cabinet assemblies as individual parts or combined assembly numbers can be an advantage.

Multiple configurable reporting options empower engineering teams to produce a complete production and assembly package.

Learn more

Related Products

E3.cable extends the functionality of E3.schematic enabling individual conductors to be combined together in the design to form cables and harnesses.

E3.panel allows engineers to layout components inside panel enclosures in both 3D and 2D. Intelligent automatic snapping points allow parts to be easily placed in their correct location.

E3.panel+ enables automatic wire routing within the panel enclosure. Connectivity data from the schematic is automatically available in the panel design, and a shortest route algorithm routes the wires through cable ducts.