The increasing complexity of products and processes demands a rethink of traditional development methods. Zuken recognizes the need for a methodological framework that spans across development domains and beyond mere technical integration. MBSE, with its standardized model-based approach, offers a structured method to tackle these challenges effectively. By integrating MBSE with proven E-CAD and data management technologies, Zuken provides forward-looking solutions for modern product development.

Understanding GENESYS for MBSE

MBSE offers a systematic approach to manage the complexities of product and process development. It’s gaining traction across various industries, such as automotive and mechanical engineering, for managing requirements complexity and optimizing product architectures. MBSE, based on the SysML standard, helps ensure a coherent, integrated development process from concept to validation.

Zuken’s extensive experience in E-CAD and function-oriented development sets its MBSE solution apart. Unlike the geometric and component-oriented methods typical in mechanical engineering, Zuken’s MBSE approach seamlessly integrates requirements, functions, and product structures. This function-oriented data management, combined with MBSE, provides a unique and effective solution for managing complex product developments.

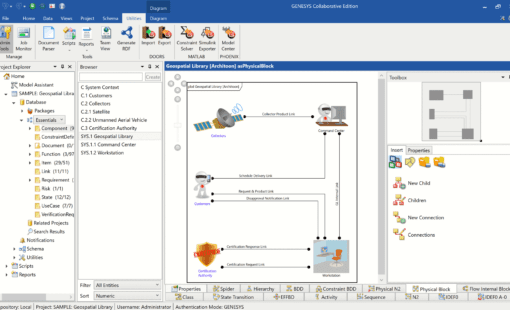

While GENESYS excels at requirements management, it offers much more. Traditional document-based requirements management often leads to difficulties in comparing and transferring requirements into products. GENESYS translates these requirements into a dynamic system model, linking them to the product structure throughout development. This method not only simplifies requirements management but also enhances product architecture.

Transferring requirements into a system model may seem like an extra step, but it streamlines the process. Understanding, structuring, and relating requirements to product development are necessary tasks. By integrating these steps into a system model, GENESYS makes the effort more transparent and manageable without increasing workload.

Absolutely. While MBSE originated in aerospace, its principles apply to any industry dealing with complex systems, such as manufacturing and plant engineering. MBSE helps visualize, understand, and simulate products during the development phase, making it a valuable tool across various sectors. Zuken’s approach combines MBSE with proven data management mechanisms, ensuring visibility and process safety in diverse applications.

Integration is a key strength of GENESYS. It offers built-in integration with popular tools like MS Office (Word, Excel, PowerPoint), MS Project, DOORS, MATLAB, Simulink, and more. Additionally, GENESYS supports custom integrations through its open API, facilitating seamless data exchange across different platforms. Zuken also provides tailored integration solutions to meet specific business needs, ensuring seamless alignment of product owners and visualization of dependencies.

Initially, transferring requirements into a system model might seem to add complexity. However, MBSE simplifies the development process by providing a clear, structured framework for managing requirements and product development. This approach reduces inconsistencies and breaks in workflows, making the overall process more efficient.

No significant restructuring is necessary. GENESYS is designed to enhance and harmonize collaboration among stakeholders by providing a unified view of the product from different perspectives. It also helps visualize, simulate, and improve processes without requiring a complete overhaul of existing systems.

Not necessarily. GENESYS is user-friendly and supports data entry through familiar tools like Excel, making it accessible to employees without requiring extensive SysML knowledge. This pragmatic approach ensures that technical sales and product management teams can continue using their preferred tools while benefiting from MBSE.

GENESYS is designed to operate on various Windows environments to ensure broad compatibility and ease of integration within most IT infrastructures. The specific system requirements include:

- Operating Systems: Windows 10, Windows 8, and Windows 7; Windows Server 2019, Windows Server 2016, and Windows Server 2012.

- RAM: A minimum of 8 GB RAM is required, with recommendations for more in server operating systems to handle the more intensive operations typical of server use.

- Additional software integrations and the use of APIs may require more advanced hardware depending on the complexity and scale of the projects being managed.

These requirements ensure that GENESYS can perform optimally in various enterprise environments, supporting the sophisticated modeling and simulation tasks essential for effective MBSE.

GENESYS is versatile and beneficial for industries such as aerospace, automotive, electronics, and plant engineering. Its ability to manage complex, interdisciplinary projects makes it ideal for sectors that require integrated, coherent development processes.

GENESYS is designed to drive digital transformation by enabling efficient, error-reduced, and integrated system design processes. It supports the creation of digital twins and integrates with existing digital and physical infrastructures, enhancing product design and development.

Yes, GENESYS facilitates adherence to industry standards and compliance requirements, particularly in regulated sectors like automotive and aerospace. Its structured approach ensures that all elements of a system meet specified requirements and function as intended.

GENESYS provides a real-time, lock-free editing environment that fosters collaboration among engineering teams. By offering a single source of truth, it ensures all stakeholders have access to the latest information, accelerating design processes and reducing errors.

Related Resources

Latest Blog Posts

- Blog

In this week’s blog post we’re sharing an exciting sneak peek of the 2021 R2 release of GENESYS, the latest version of our model-based systems engineering development platform, including a new language option and an extended API.

- Blog

Alex Grove, Account Manager at Zuken, talks about his personal MBSE journey, what his customers experience when embarking on such a journey, and the upcoming Annual Systems Engineering Conference.

- Blog

Digital Transformation should go beyond a simple mapping of analog documents and processes into the digital domain. This blog post explores new ways and opportunities to enhance today’s methods and processes for increased efficiency and accelerated innovation.

- Blog

Many manufacturers are harnessing systems engineering approaches to mitigate the complexity of developing increasingly sophisticated products. Systems simulation is a key component of such efforts.