Haulotte Achieves Engineering Efficiency by Integrating ARAS with Zuken

Haulotte, a renowned global player in the field of aerial work platforms and material handling equipment, has selected Zuken’s E3.series for a significant integration with the ARAS PLM system. This choice has enabled Haulotte to optimize its work methodology and project more confidently and efficiently toward future developments.

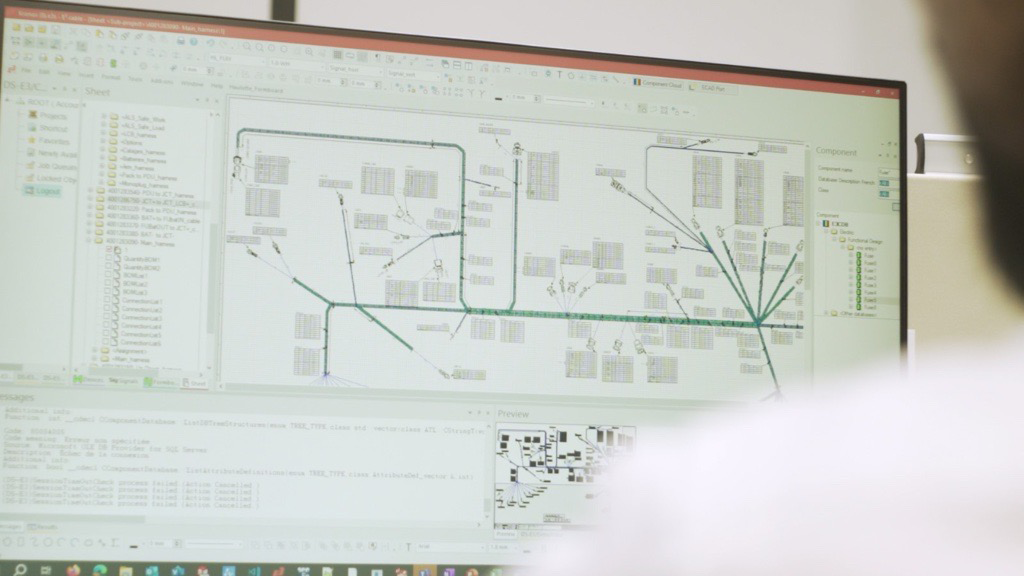

After using a different design software for years, Haulotte’s Engineering Department decided to switch to a more powerful system capable of connecting electrical schemas and wire wire harness designs as well as integrating seamlessly with the company’s PLM systems. One year after its introduction, Haulotte engineers share their experience with the E3.series & DS-E3 solutions for designing and constructing – sometimes very complex – lifting systems.

Today, Haulotte Group employs 2,000 people worldwide, with 5 factories and 21 subsidiaries. The group designs, manufactures, and markets a wide range of aerial work platforms. Experiencing strong growth, the 2022 turnover exceeded 600 million euros.

As a strategic partner, Zuken supports Haulotte in the development of products that incorporate a significant portion of innovation and technology.

Launch of the Zuken Project

In 2018, Haulotte initiated a significant step in its technological advancement by implementing the ARAS PLM system. To further enhance its responsiveness to market demands and technological efficiency, Haulotte integrated Zuken’s DS-E3 for data management. This strategic move ensured a seamless integration between DS-E3 and ARAS, boosting Haulotte’s operational capability.

The successful deployment and testing phase marked Haulotte’s transition into full operational status with the new system, meeting the expectations of both customers and internal users.

The Engineering Department, consisting of 70 professionals across four global locations, plays a pivotal role in this transformation. Their primary task involves developing innovative aerial work platforms by identifying optimal technical solutions, including the design of control components and electrical harnesses.

Embracing this project, Haulotte faced significant challenges, but through a collaborative effort with Zuken’s experts, they streamlined their work methodology. This partnership led to a bespoke solution, effectively incorporating Haulotte’s unique requirements.

Before this, Haulotte’s approach involved using two separate, manual-intensive software tools for electrical diagrams and harnesses. The shift to E3.series facilitated an automated, consistent link between these aspects, enhancing documentation quality across technical and related departments, like production and series life.

Results

The clear benefits that Haulotte engineers found in using the E3.series and DS-E3 solutions can be summarized in three main points:

- More efficient design work, minimizing low-value-added operations and spending more time on engineering diagrams.

- A significant reduction in the risk of errors and inconsistencies.

- Direct integration with the ARAS PLM system through a unique and intelligent database that perfectly meets the needs of the engineering department.

We can confidently say that the challenges we faced have been overcome, and today we highly recommend Zuken.

Discuss your design issues with our experts

Related Content

- Software Evaluation

E3.series Test-Drive provides a web-based training course that guides you through the creation of a real life design example with E3.series using E3.cable and E3.panel

- Webinar

Who doesn’t recognise this? Many versions, many intermediate results, many copies, who has the latest version? Where is it stored? Who is currently working on it? Which settings, structure and database is the right one? We want to answer all these questions in this presentation.