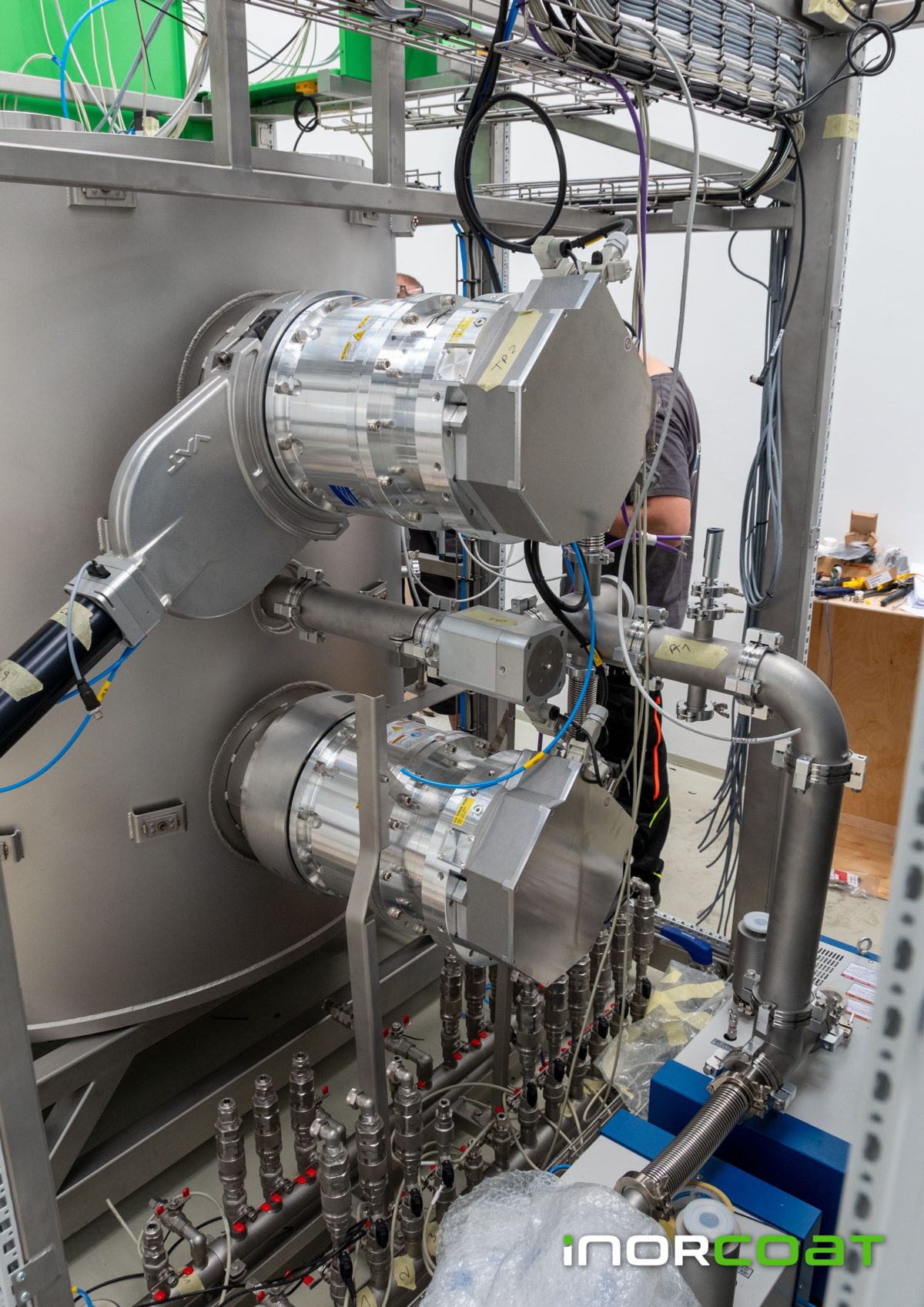

Galvanic chrome plating is commonly used in industrial applications to increase the resistance to wear. However, it has a serious disadvantage: it is highly harmful to the environment and will have to be replaced by alternative processes. These are in fact available with plasma coating technology – also known as PVD (physical vapour deposition) in technical jargon – but they are currently too expensive and inefficient for many industrial applications.

It was this shortcoming that Romain Waidelich set out to remedy with his start-up company INORCOAT. His vision is “to simplify the complex plasma coating or PVD process and make it more understandable and accessible to the customer.”