NOTE: A German language version of this webinar is also available – Register here.

Save up to 60% in time and efficiency

In control cabinet construction, complete proof of the installation of the machine/system and its components is required over the entire life cycle. This usually requires labelling in accordance with DIN EN ISO 81 346.

Are you wondering how this can work in times of increasing product diversity, fast-moving changes and a pronounced shortage of skilled workers? You will find the answer in this webinar.

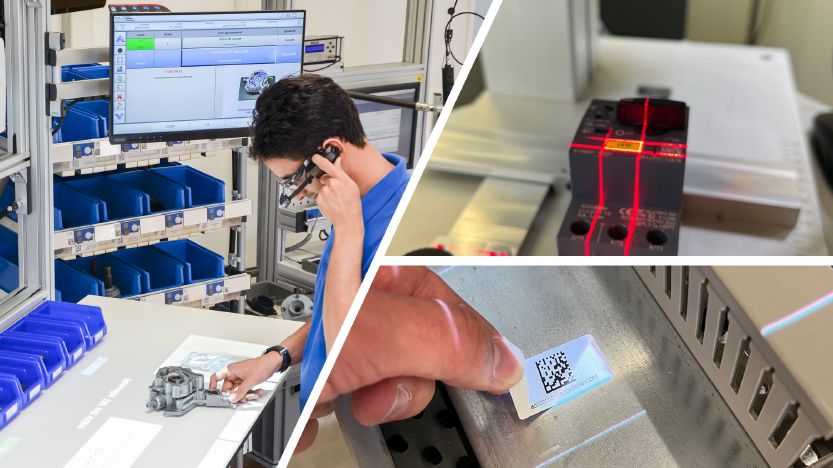

By implementing digitalization and automation, our partner Armbruster and Weidmüller show you how the picking, labelling and assembly steps will help you save up to 60% per process step in time and efficiency.

In addition to the ELAM assistance systems from Armbruster, our partner Weidmüller will present the THM MultiMark LPC (Labeling Processing Center) from Weidmüller, a unique solution for automatic component labelling.

Learn from the Expert

- Timo Tessin – Key Account Manager at Armbruster Engineering

- Malte Zapf – Sales Representative at Armbruster Engineering

- Faysal Dogan – Strategic Product Manager at Weidmüller

Who should attend

- Plant Managers

- Production Managers

- Production Planners

- Sales Managers

- Electrical Hardware Designers.