“It was a deliberate decision to rely on a best-in-class solution that combines two specialized toolsets.”

– Dr. Goy Hinrich Korn, CIO, KRONE

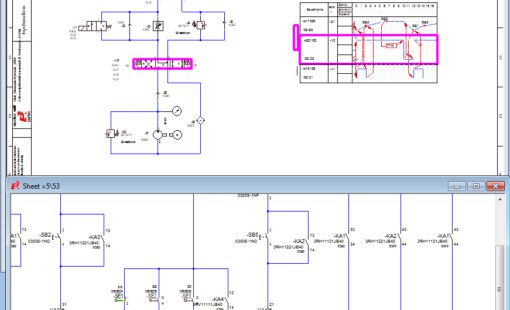

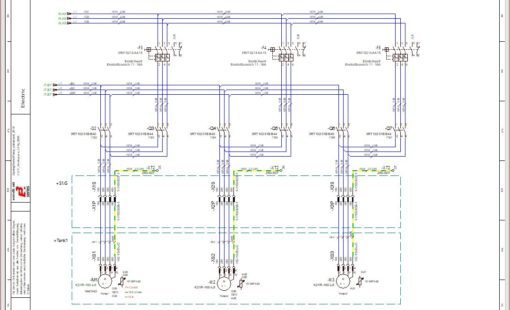

“Today, we have all mechanical, hydraulic and electrical assemblies available in one information source. This puts us in a position to build a number of robust downstream processes on them.”

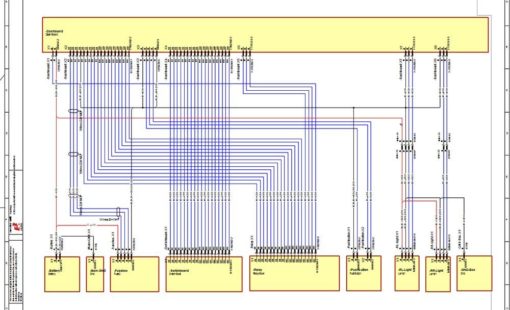

“The interface between E³.series and CATIA® brought our cable harness design much closer to the physical design world.”

– Stefan Thygs, System Administrator, Electrical Engineering, KRONE

“Today, we are in a position to produce detailed cable harness drawings and bill of materials that the supplier can directly use for harness manufacturing.”

– Michael Blume, Head of Technical Applications, IT Department, KRONE