Digitally assisted wiring and documentation for machines, vehicles, and control cabinets

Munich, Germany, and Westford, MA, Oct. 20, 2020 – Zuken announces three new applications for the digital assistance and documentation of the wiring process for machines, vehicles, and control cabinets. The new E3.series applications E3.AssemblingCockpit, E3.WiringCockpit and E3.WiringChecks provide operators on the shop floor with all information required for assembling, wiring, and commissioning in a paperless form via portable terminals.

The new applications extend the existing E3.series manufacturing interfaces for cabinet machining and wire processing, offering a digital alternative to today’s paper-based assembly and start-up documentation practices. They have been developed in close cooperation with leading customers in the mechanical and automotive engineering sector, where they are already in productive use.

Many companies in the machinery and transportation sector still rely on paper documents for the wiring assembly and documentation.

With E3.AssemblingCockpit, E3.WiringCockpit and E3.WiringChecks, all documents required during the wiring and commissioning of a new machine or vehicle can be generated directly from an E3 project and visualized on a portable device. With this assistance, even less qualified workers can confidently follow through the single steps. The solution records and documents every single wiring step; any adjustments and corrections that need to be made during production can be documented and reported to the engineering department in a digital format, thereby satisfying the needs for consistent change management.

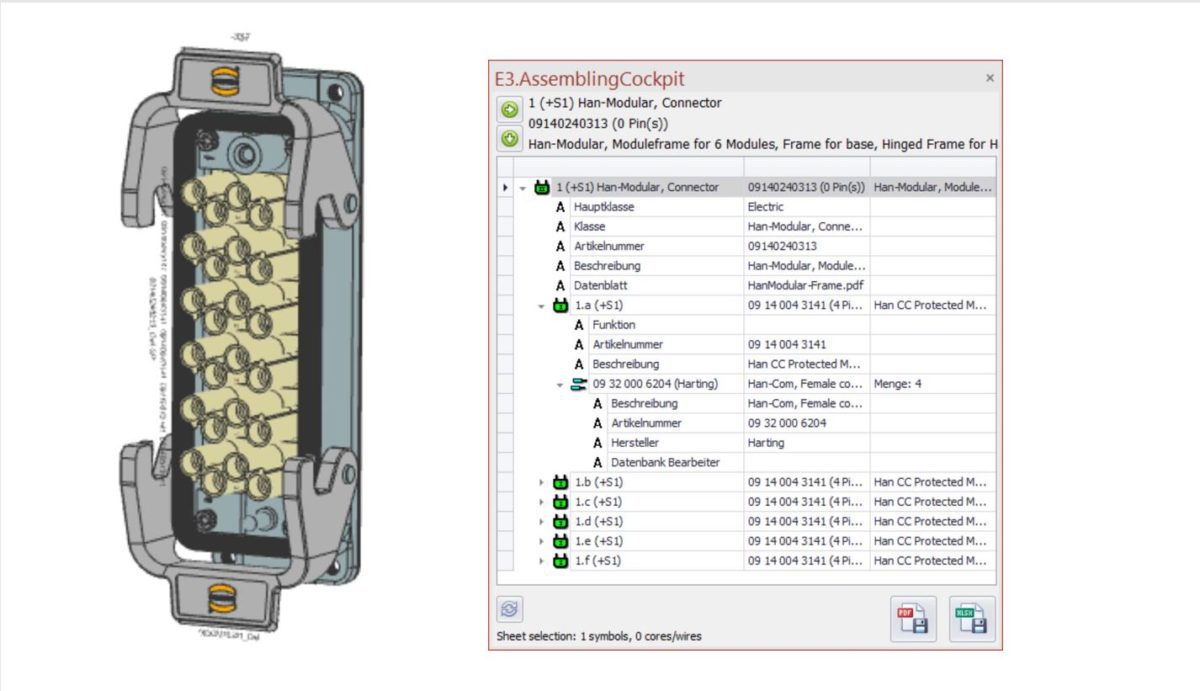

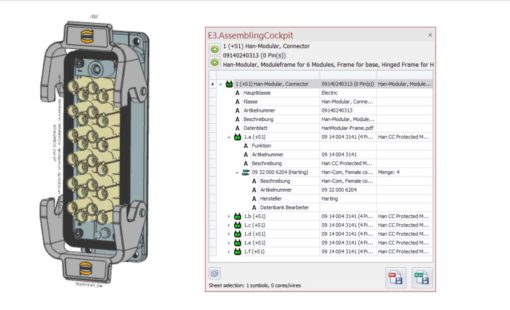

Digitally assisted assembly of modular components

E3.AssemblingCockpit assists shop floor staff during assembly of modular connectors and other component assemblies, which need to be assembled from a comprehensive component kit. The application lists all required components, such as connector housing, frames and plug inserts as well as mounting parts and accessories, so that the worker can focus with confidence on the correct assembly

Info E3.AssemblingCockpitDigitally guided wiring

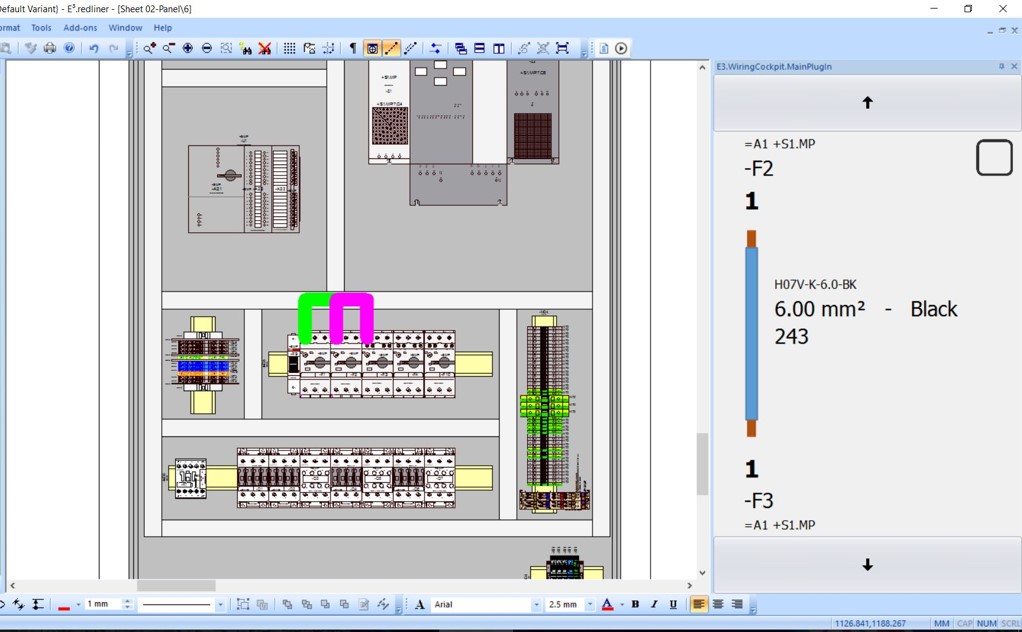

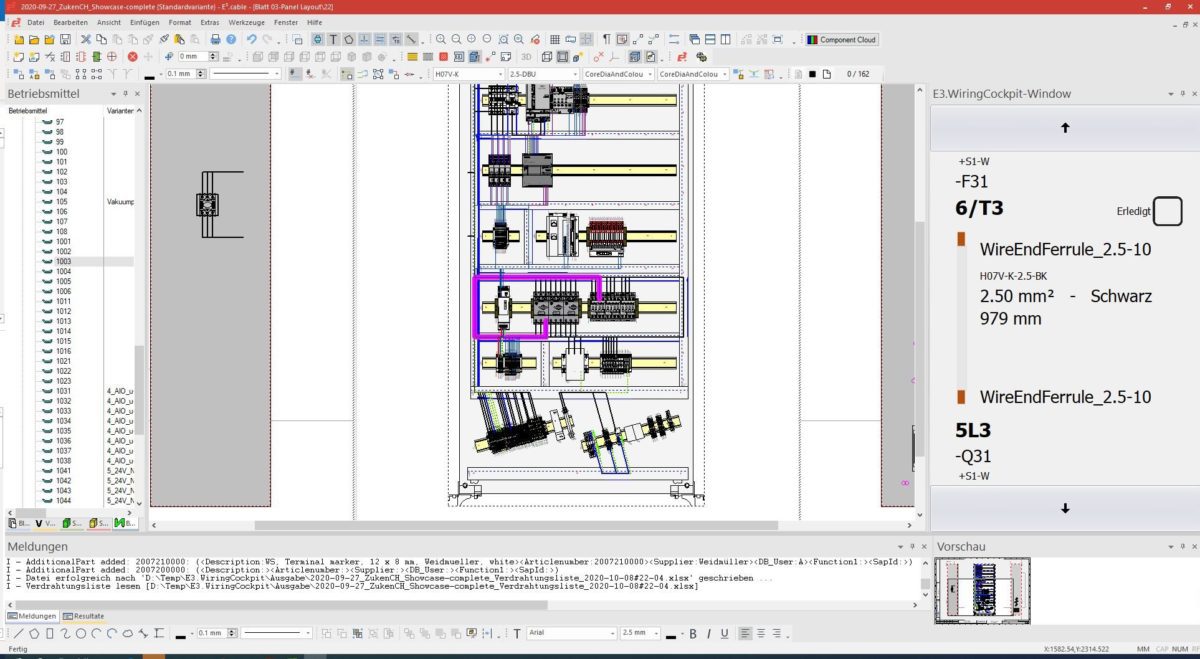

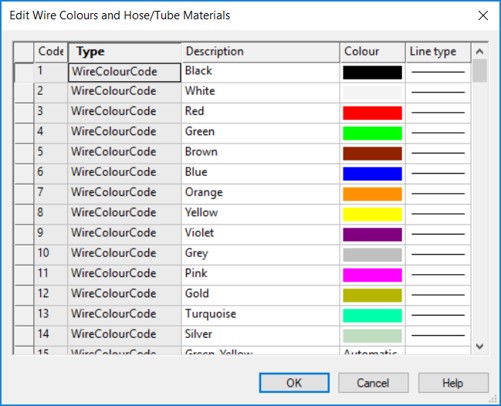

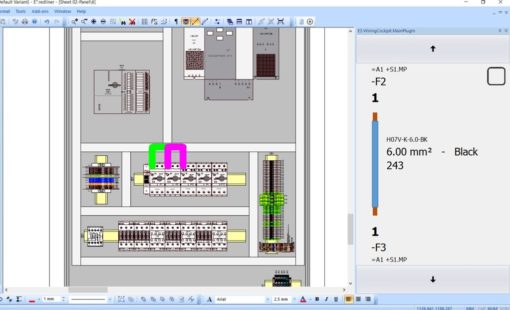

E3.WiringCockpit enables the definition of an optimized wiring sequence, through which the operator can be guided step by step. For every connection in the wiring sequence, the wire paths are highlighted in the 3D control cabinet design, and all information needed to establish a correct connection is displayed in a dedicated window. After completion and confirmation of a connection, the next wire will be displayed. The progress of the single wiring steps is fully documented so that work can be interrupted and continued at any given time at exactly the point of interruption.

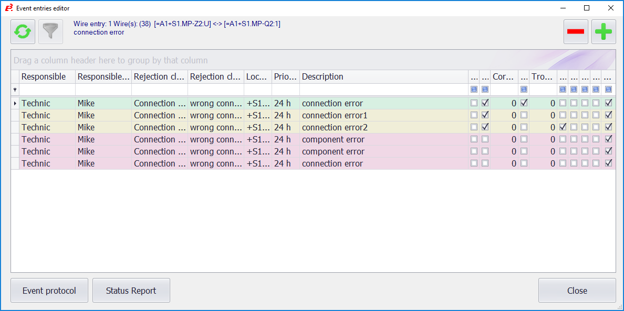

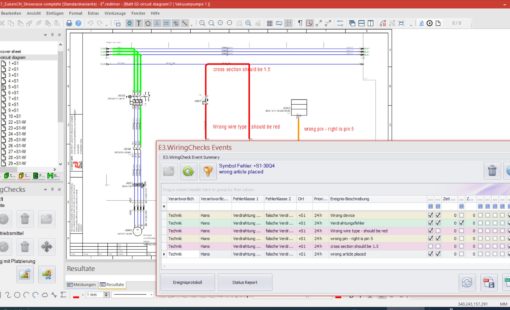

Info E3.WiringCockpitDigitally assisted commissioning test

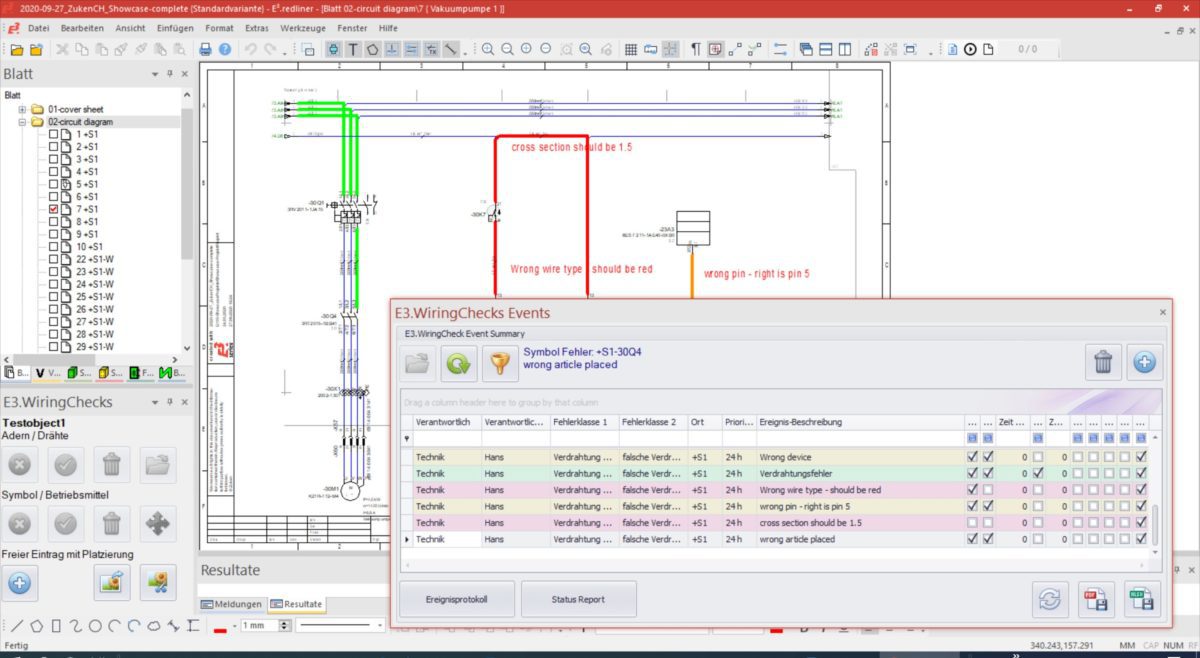

E3.WiringChecks supports the verification of the completed wiring installation of a machine, vehicle or control cabinet before or during the start-up. The results are documented as part of an E3 project; evry completed checked wire and device check is digitally recorded and marked as checked or error. In the event of an error, an event can be created and placed in the schematic digram. Error descriptions can be exported and forwarded to the engineering department for correction and resolution.

Info E3.WiringChecksRelated Products and Solutions

- Products

E3.AssemblingCockpit helps workers in the assembly department to select and assemble the individual parts for modular connector assemblies and other components that have to be assembled from comprehensive parts kits.

- Products

E3.WiringChecks assists the testing of fully wired machines, vehicles and control cabinets before and during the start-up phase.

- Products

E3.WiringCockpit enables the display of wiring paths and connection information on mobile devices.

- Solutions

Weidmüller, Komax, Zuken, nVent Hoffman / Steinhauer and Armbruster Engineering launch the SMART CABINET BUILDING initiative