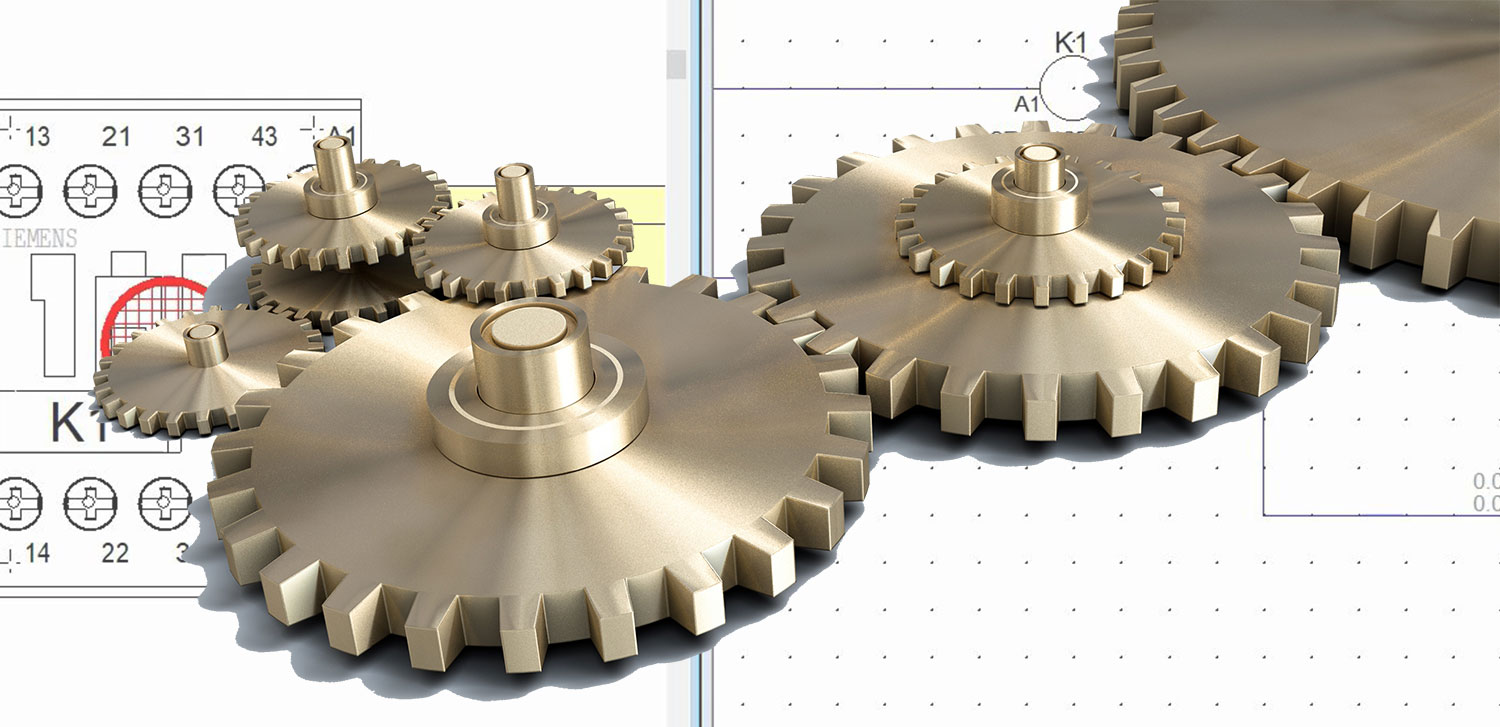

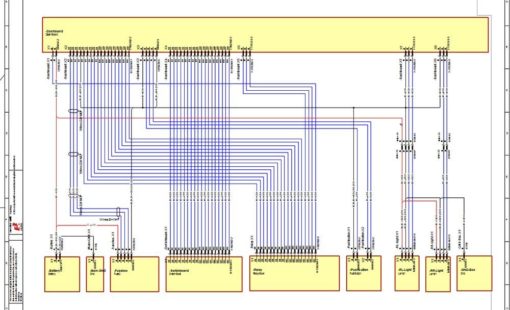

The automation or configurability of designs is a goal every team wants to achieve, but most teams haven’t seen success mainly due to not having the right tool to get the job done. Electrical design tools that were once used by a vast number of companies originally came as extensions of mechanical design tools, or were very often just basic drafting tools. The ability to create exceptional designs without errors and do it in a fraction of the time required by other tools is the major reason why E3.series is so effective in helping design teams.

Options and Variants in E3.series provides an ideal platform to put together a design that can be configured to meet your requirements. The Options and Variants can be applied to Schematic, Harnesses and Panel designs with as much or as little detail as required. The ability to create complex combinations using Boolean logic and other methods gives you the ability to expand the use of options into small and large projects alike.

E3.series automatically updates the drawing and the entire project concurrently – including Bills of Materials, reports and documentation – helping to exponentially increase productivity throughout the design process.

Related Content

- Products

- Products

E3.cable extends the functionality of E3.schematic enabling individual conductors to be combined together in the design to form cables and harnesses.

- Products

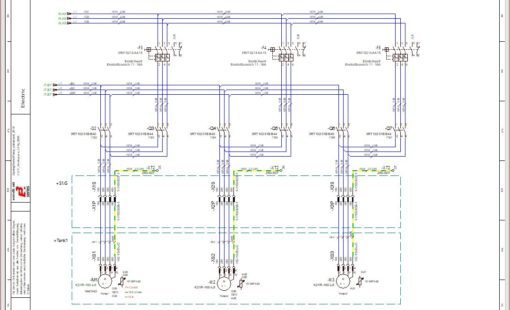

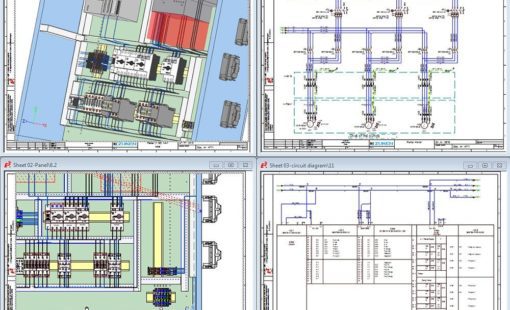

E3.panel allows engineers to layout components inside panel enclosures in both 3D and 2D. Intelligent automatic snapping points allow parts to be easily placed in their correct location.

- Products

E3.series is a true concurrent electrical engineering environment supporting advanced requirements for electrical documentation, cabinet and wire harness design and manufacturing outputs.