- Case Study

Mecalac designs and manufactures heavy plant vehicles for use in construction. Their vehicles – backhoe loaders, site dumpers and compaction rollers – are each offered in several variants. They all need to work in harsh environments.

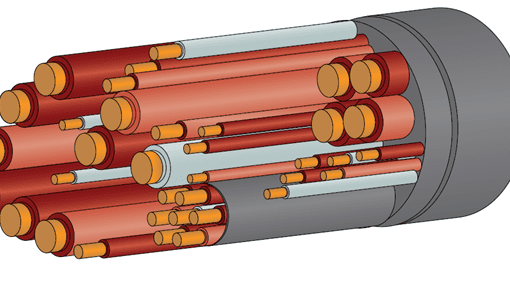

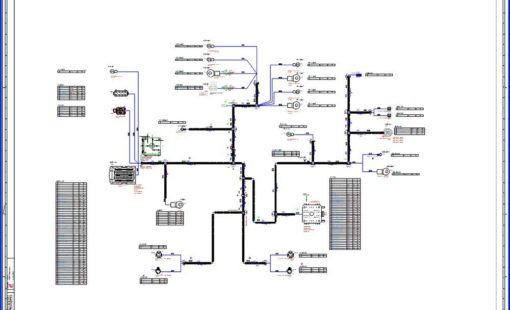

A wire harness design requires both a 3D physical representation and a logical representation of connections, device and component characteristics. With comprehensive information exchange capabilities between E3.series and all major MCAD systems, and powerful wire harness design and manufacturing outputs, Zuken provides a comprehensive approach to wire harness engineering.

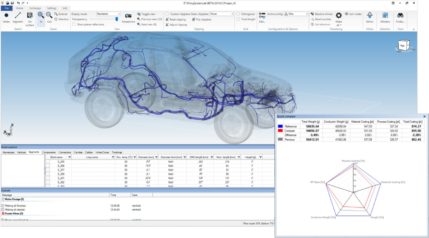

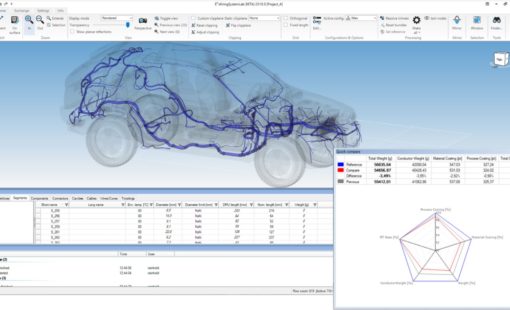

Optimization of complex wire harness designs based on inputs from heterogeneous sources. Specialized functionality tailored specifically to topology exploration provides the ability to create and evaluate different architectural concepts.

Coherent multi-sheet print outputs and support of industry standard formats such as PLMXML, KBL and VEC. Comprehensive manufacturing outputs including connection tables, clips, heat-shrink and convolute information.

Bidirectional integration with cable planning, enabling automatic synchronization of changes in both manufacturing documentation and wiring diagrams ensures a seamless and error free design flow in a consistent environment.

Zuken Inc., and Electro Magnetic Applications, Inc. (EMA) have entered into a partnership to improve the accuracy of cable harness simulation models for complex electrical subsystems in aircraft and vehicles

Feumotech’s fire trucks are custom made and highly specialized. This usually equals immense development efforts. By using Zuken’s E3.series electrical engineering software, the Swiss manufacturer was able to significantly reduce the development effort per vehicle. At the same time, they were able to increase the quality of their electrical design documentation.

The season to be jolly is just around the corner. We are getting ready to open up our favorite gifts and sip hot cocoa around the fireplace. E3.series users had a lot of reasons to be jolly with the 2019 update bringing in a ton of features and updates. The updates in E3.series 2019 cover the breadth of the solution and there is something for almost every aspect of the design suite. The best sentiments to describe the overall release are ‘intuitive’ and ‘efficient’.

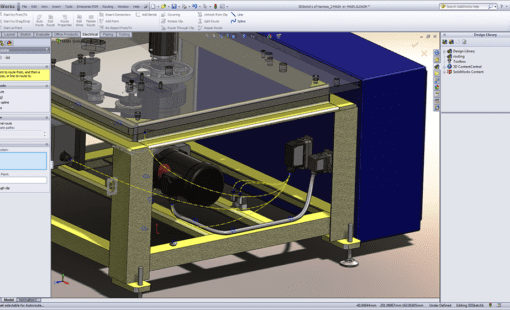

This webinar follows looks at the physical part of the wire harness design process: Routing of the harness in the physical (3D) design space

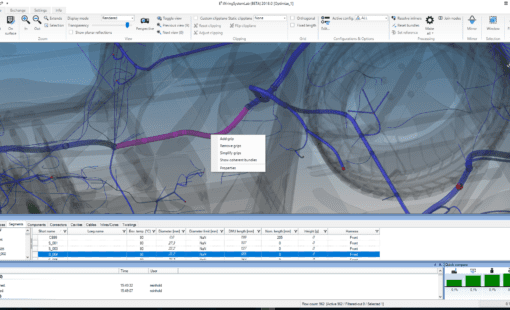

E3.WiringSystemLab enables the optimization of wire harnesses with an unprecedented degree of speed and accuracy. With these capabilities, it generates substantial benefits across a wide spectrum of applications in the automotive and transportation industry.

E3.3DRouting Bridge - Streamline ECAD-MCAD collaboration by synchronizing connectivity data between E3.series and leading MCAD platforms in real-time.