Machinery

Electrical Wire Harness Design Software

Zuken’s powerful and versatile wire harness design software is designed for various industries, including transportation, defense, aerospace, machinery, and consumer electronics. The intelligent and purpose-built library structures help capture critical manufacturing data to improve the design-to-manufacturing workflow. The digital formboard automatically determines wire lengths and a packing algorithm calculates the outer diameter of harness segments.

Interactive automation functions, placement, sizing, dimensioning, and routing of harness components and branches are simplified. Industry partnerships create a collaborative ecosystem to drive automated testing, manufacturing, and assembly. Comprehensive reporting capabilities help extract data from the design to produce wire lists, bills of materials, quotations, labels, and design packages for connected business systems.

Industries

Automotive

Aerospace

Special Vehicles

Create Wire Harness Designs from Connectivity Data

Design teams often receive connection data, wiring details, and block configurations internally or from suppliers and OEMs. Manually entering or recreating the data is one of the most common sources of error. In E3.series, you can import connection data or PCB pinouts stored in Excel or CSV files to speed up the design process.

E3.series gives users the flexibility to define and map the column configuration without adding complexity to the import process. By linking PCB blocks in the project to external files, engineers can interactively update design data, eliminate rework, and accelerate the design process.

Cable & Wiring Harness Builder

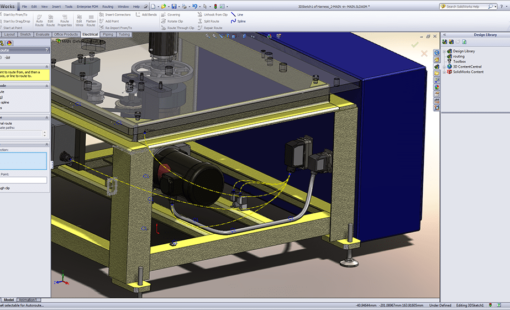

Starting Designs from MCAD

Improving collaboration between MCAD and ECAD teams without redefining their respective roles benefits all teams involved. Although electrical engineers own the logical connectivity and wire sizing, mechanical constraints and route lengths are highly dependent on the physical characteristics of the routing path. Using native files from leading MCAD tools and industry-standard formats brings unparalleled flexibility to the collaboration process.

Harness flattening capabilities simplify the transition from a 3D harness export to a 2D formboard drawing. Connectivity between logical and physical architecture improves data reliability with automatic updates throughout the project.

3D Routing Bridge Form Board

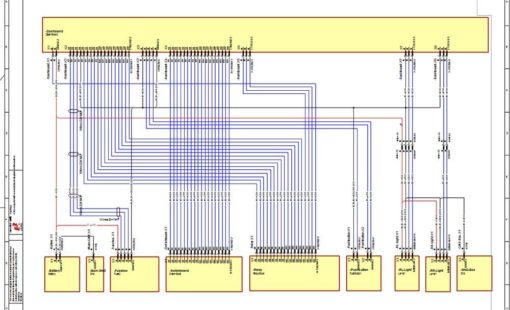

Electrical Systems Topology

E3.topology takes logical designs into the physical world. Topology sheets created at any scale, can be added to the overall E3.series project. Sheets can represent chassis or plant layouts, including installation spaces such as the dashboard or equipment, and then be added to the project.

The connections between these spaces represent wiring harness routes or cable runs. Alternate views of logical devices are also included in the same project and displayed in their respective spaces.

Topology Cable & Wiring

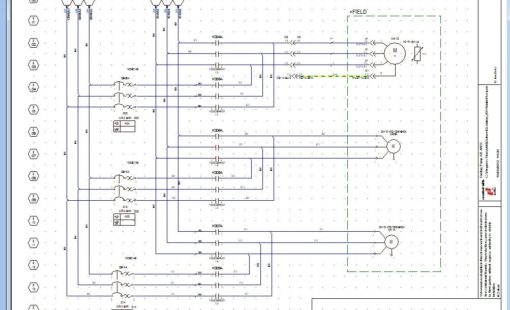

Functional Analysis and Circuit Checks

The intelligent component library, custom kernel, and numerous design rule checks are optimized for electrical design. The prevention of short circuits and incorrect part usage ensures that the correct design data is always available for manufacturing.

Unique objects such as power sources, fuses, switches, complex devices, and loads in the E3.series library facilitate functional checks. Power supplies allow the user to simulate the circuit, while fuses monitor the inline current. A real-time view of the system allows engineers to analyze the system and create a right-first-time design focus.

Circuit Simulation Electrical Schematic

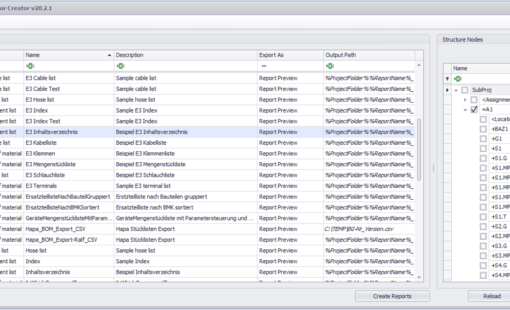

Automating Quotes and Reports

Upstream and downstream processes can be supported by the automated generation of estimates, quotes, bills of materials, wire lists, and many other reports. Customizable reports can be used for estimating purposes or for bills of materials.

Intelligent reporting tools help users create customizable report templates with export options for multiple file formats. Pre-configured connectors enable the direct export of reports to leading PLM and PDM solutions. The free, open API access gives users unfettered access to further customize connectivity and reporting.

Report Generator Harness Builder

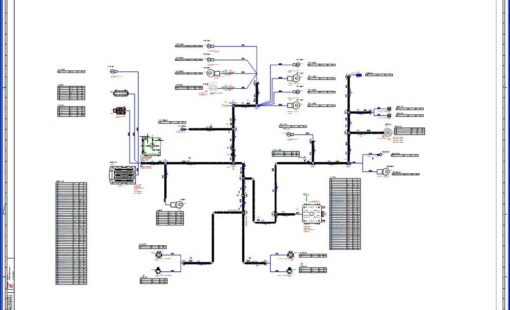

Automating the wire harness design process

E3.series harness design tools transform a predominantly manual formboard layout and detailing process into an intelligent automated process. The wire harness design uses the same data from the schematic to drive the formboard creation. The formboard drawings allow designers to create 1:1 scale manufacturing or scaled documentation drawings without sacrificing manufacturing data or length calculations.

E3.series excels at accurately calculating the outer diameter of sections or bundles of a wire harness. Designers can now report the diameters of various segments in a wire harness using an always up-to-date display text. The automated tools use segment diameters to add harness protection, labels, tapes, and other accessories, dramatically improving consistency and reducing design overhead. Automatic formboard tables display up-to-date connector and harness assembly information to eliminate data entry errors.

Form Board Harness Builder

Connecting with Testing Machines

Easily drive automated wire harness testers directly from the design details. Export options for Cirris, DIT-MCO, Dynalabs, CamiResearch, Nexeya, CKT Technologies, and more provide an easy path to improved quality and time savings. Teams save time and effort by fully leveraging the data captured in the design to simplify the test creation process.

Zuken’s ever-expanding partnerships and connections allow harness designers to connect to leading testers to meet various industry requirements. Export and connectivity options provide solutions ranging from simple CSV exports to native data files for the devices.

Harness Builder

Driving Manufacturing Automation

The intelligent logical and physical harness data is the driving force behind the multitude of manufacturing automation options in E3.series tools. Wire information in the library and the wire lengths from the project provide accurate data for wire cutting and processing machines.

The device and wire tags, labels and other annotations are available in configurable output formats to connect to leading labeling, marking and printing options. Dynamically configurable data drives machines of all sizes from leading manufacturers such as Schleuniger, Komax and Argus. Connect to intelligent, augmented, intelligent assembly aids such as ProjectionWorks and Laselec to make the leap to the digital transformation of the manufacturing process.

Harness Builder

- Products

E3.schematic offre aux ingénieurs électriciens une solution conviviale pour la conception et la documentation des systèmes de commande électriques, notamment des schémas, des plans de bornes et des PLC.

- Products

E3.cable, logiciel de conception de câbles électriques, est utilisé pour la conception et la documentation de plans de câbles et de dispositions de faisceaux

- Products

Exportation des listes de câbles pour les machines de traitement des câbles Komax

- Products

- Products

- Products

The E3.ReportGenerator is a free tool for creating customised reports from E3.series projects in a few simple steps. These reports can be configured according to various parameters and exported in various formats. The tool requires no licence and can be launched directly from within E3.series.