- Case Study

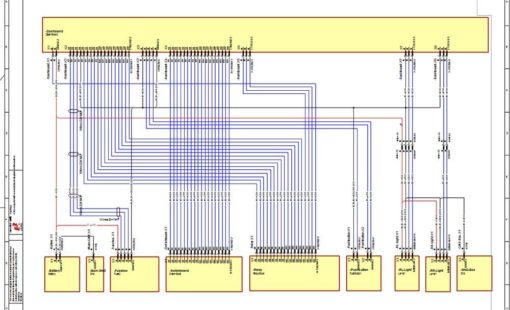

Direct use of schematics and wiring data for manufacturing, assembly and service provides a proven way of increasing efficiency and accuracy in product development. Creating manufacturing and serive documents from design data avoids error prone manual re-entry of data and ensure a controlled changed in an end-to-end environment.

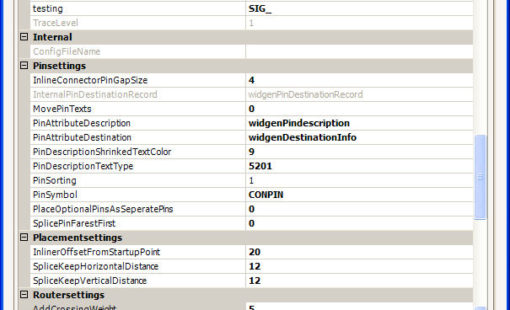

Automatically generated schematics/wiring diagrams for assembly, service and after sales support.

Direct integration with cable planning enabling automatic synchronization of changes in both manufacturing documentation and wiring diagrams.

Direct integrations to wire cutting, stripping and labeling machines to enable an error-free transition to manufacturing.

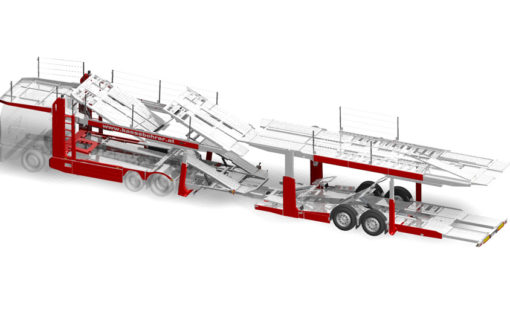

E3.cable, logiciel de conception de câbles électriques, est utilisé pour la conception et la documentation de plans de câbles et de dispositions de faisceaux

Exportation des listes de câbles pour les machines de traitement des câbles Komax