- Case Study

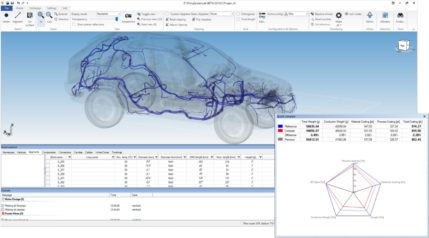

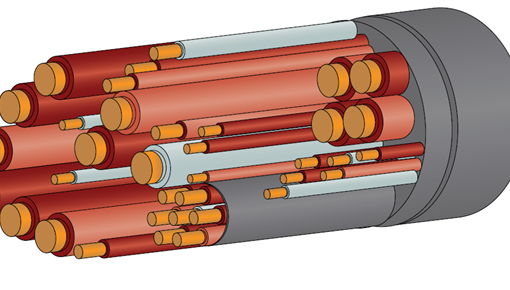

A wire harness design requires both a 3D physical representation and a logical representation of connections, device and component characteristics. With comprehensive information exchange capabilities between E3.series and all major MCAD systems, and powerful wire harness design and manufacturing outputs, Zuken provides a comprehensive apprach to wire harness engineering.

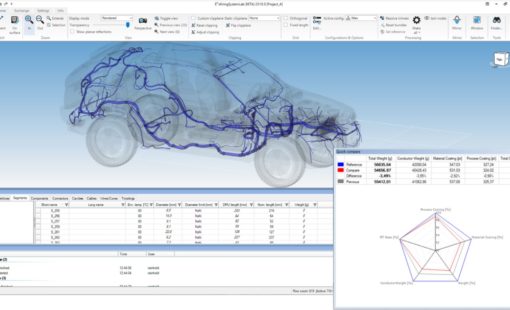

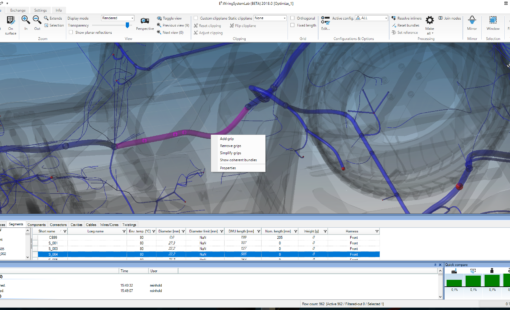

Optimization of complex wire harness designs based on inputs from heterogeneous sources. Specialized functionality tailored specifically to topology exploration provides the ability to create and evaluate different architectural concepts.

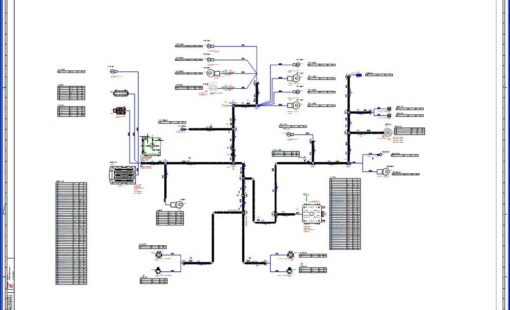

Coherent multi-sheet print outputs and support of industry standard formats such as PLMXML, KBL and VEC. Comprehensive manufacturing outputs including connection tables, clips, heat-shrink and convolute information.

Bidirectional integration with cable planning, enabling automatic synchronization of changes in both manufacturing documentation and wiring diagrams ensures a seamless and error free design flow in a consistent environment.

Zuken Inc., and Electro Magnetic Applications, Inc. (EMA) have entered into a partnership to improve the accuracy of cable harness simulation models for complex electrical subsystems in aircraft and vehicles

E3.WiringSystemLab permet l'optimisation des faisceaux de câbles avec un degré de rapidité et de précision sans précédent. Avec ces capacités, il génère de considérables avantages à travers un large spectre d'applications dans l'industrie automobile et des transports.