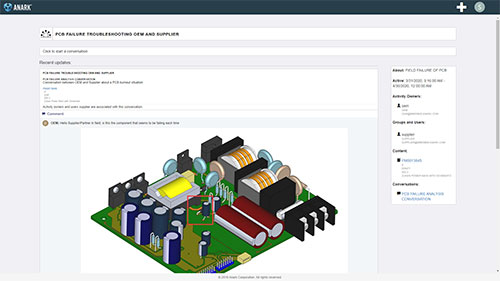

Spanning The Extended-Enterprise

A browser-based approach allows for faster deployment and easier adoption lead to productive multi-organization interactions. An activity such as a design review or a part procurement can be broken down into digital conversations across design disciplines or in the case of procurement, across suppliers. The conversations can start with a technical data package but can be expanded with images or new documents. The conversations are retained for a historical record of how decisions were ultimately made.