PCB Assembly drawing creation

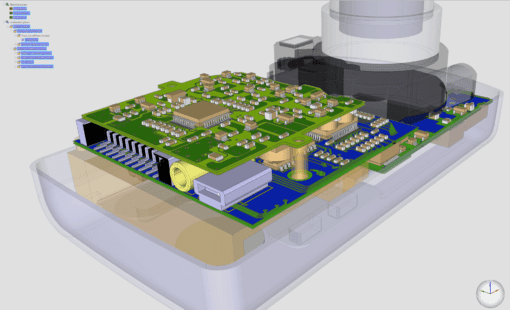

DFM Elements is used for fabrication and PCB assembly drawing creation, manufacturing verification, CAM output, and panel design. DFM Elements’ graphical user interface enables you to carry out all of these functions with the same operational look and feel as Design Force.

PCB Assembly drawing creation

Manufacturing verification

CAM output and panel design

The production of accurate manufacturing data is critical in achieving rapid time-to-market and high product quality. Zuken’s DFM tools provide manufacturing audits and outputs to ensure that boards are built correctly the first time. They support the latest manufacturing technologies, including build-up boards, HDI, and embedded components.

DFM Elements provides support for both layout and manufacturing data, allowing manufacturing features to be easily integrated into the design. Non-conductive patterns may be added during manufacturing preparation, with the manufacturing rules database monitored in real-time during the process.

Formats, text, and dimensions are all easily managed using the various DFM Elements drawing functions. The drawing functions also include scale by area and generate hole drawing. Scale by area can be used to create either a rectangular or a circular scaled figure, with support for both scaling up and scaling down. Generate hole drawing will quickly generate information for all holes in the board or panel, including holes in child boards, child panels, or grandchild boards.

DFM Elements includes an Advanced Design Rules Check For Manufacturability (ADM) client that provides manufacturing checks which support both partial and full design audits. The checks can be run locally from your desktop or from an ADM check server. DFM Elements data can also be read into Zuken’s CR-8000 DFM Center for extended manufacturing checks.

Outputs include photo (RS-274D and RS-274X), drill (Excellon2, G81, Hitachi), DXF, ODB++ and IPC-2581. Since DFM Elements uses the same database as Zuken’s PCB Design tool Design Force, the CAM data output can be compared with the source data to verify that all information has been properly extracted.

Powerful functions allow efficient design of manufacturing panels. Rules are dynamically checked during the design cycle including carrier rail clearances, child-to-panel clearances and child-to-child clearances. Single, multiple or mixed PCBs may be mounted in the same panel, and boards can be flipped to accommodate copper consistency across the panel. Automatic surface generation allows the panel to be flooded with copper and meshed.

Related CR-8000 Products

CR-8000 Design Force is the fastest, most effective PCB design solution available today. Design Force enables design teams to layout and verify their designs in the context of a complete system or product.

With a robust set of features for data preparation and embedded verification to verify manufacturing specifications, DFM Center addresses the challenges of the manufacturing process.