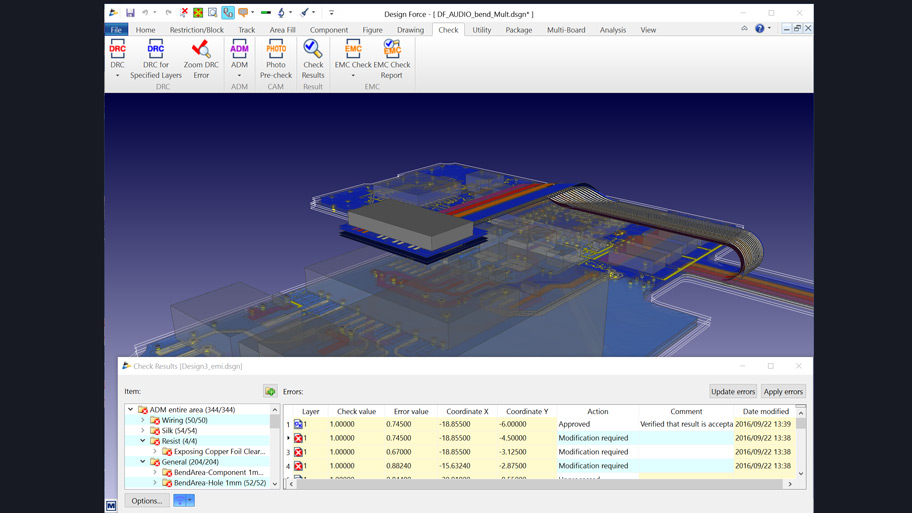

Design for Manufacturing – ADM

In the design and production of electronic products, manufacturability checks are difficult to perform manually and are often made after the design process has been completed. However, the increasing costs and design/production delays caused by higher signal speeds, ecological problems and increasing global design collaboration, make this approach unsustainable.

Zuken’s Advanced Design for Manufacturing (ADM) system ensures that designs have been produced in accordance with component mounting and manufacturing specifications early in the design process, and concurrently as the work progresses.

The system facilitates the sharing of personal expertise using company Intranet networks, and efficiently manages the growing number of design rule checks needed to ensure manufacturability.

ADM will help users to maintain all parameters needed for checking. When changes are made to manufacturing specifications and mounting processes, rules can be easily amended and checks modified. The whole process becomes front-end driven, sharing data in real time across all departments, divisions, and companies involved in the design and development of an electronic product.

Top features and benefits

- Single fabrication and assembly checking platform for any board technology, including rigid, fl ex, embedded components, and LTCC

- Web-based rules manager enables easy setup of manufacturing rules

- Checking engine is embedded across tools to allow concurrent verification of manufacturing rules any time in the design process

- Validate and optimize designs to ensure requirements are met for multiple sources for manufacturing

- Over 900 rules in 96 groups to support improvement in product quality and yield

- Create additional rules through easy to-use wizards

- Automatically generate spreadsheet report with screenshots to ease documentation and communication