A more efficient design flow for IC power modules

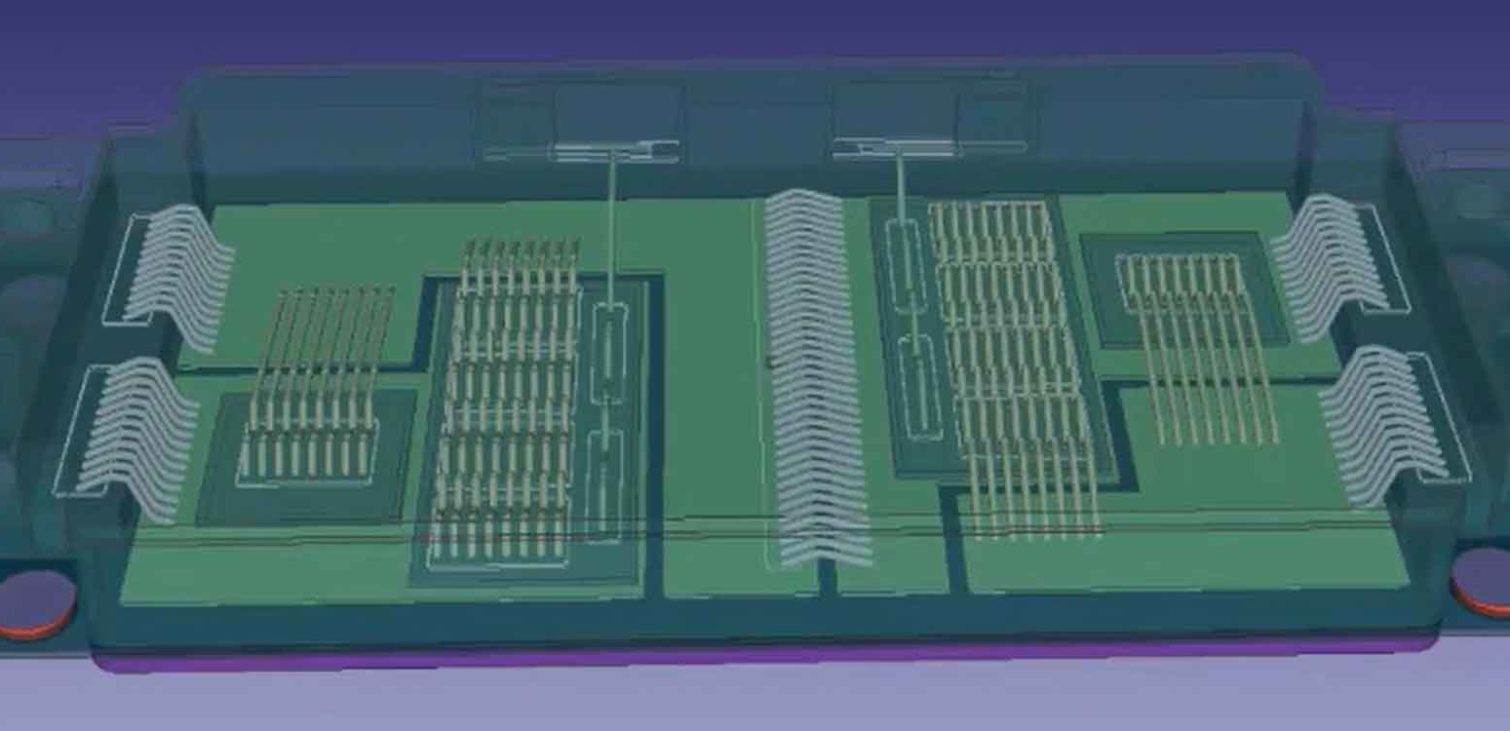

A power module provides the physical containment for several semiconductor devices on a PCB. These power modules are typically soldered or sintered on a substrate that provides electrical and thermal contact and electrical insulation where needed.

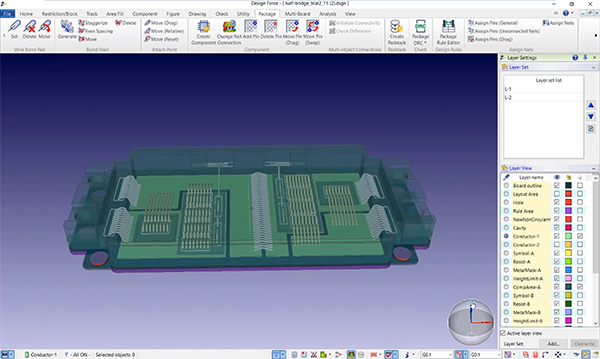

Compared to discrete power semiconductors in plastic housings, power packages provide a higher power density and are in many cases more reliable. The typical power module design flow is in MCAD, where a just structural analysis, but no electrical analysis is performed. Combining electrical and mechanical power module designs in CR-8000 Design Force can enable additional electrical analysis and identify issues that would not be found in the structural analysis.

What you will learn

- Overview of the Power Module Market

- Current power module design flow for and issues faced in the design process

- Introduction of an enhanced power module design flow using CR-8000 Design Force, including the features and benefits of this new design approach.

The session will conclude with a demonstration of how this design flow works within CR-8000 Design Force.

Learn from the expert

Iyad Rayane

European Technical Solution Architect

Zuken SA, France

Iyad Ryane is European Technical solution’s architect for the 3D-IC/Advanced Packaging and Co-Design Environment. He has worked on Digital and AMS back-end design flows with a strong experience in customer support. Iyad has been with Zuken since 2016.