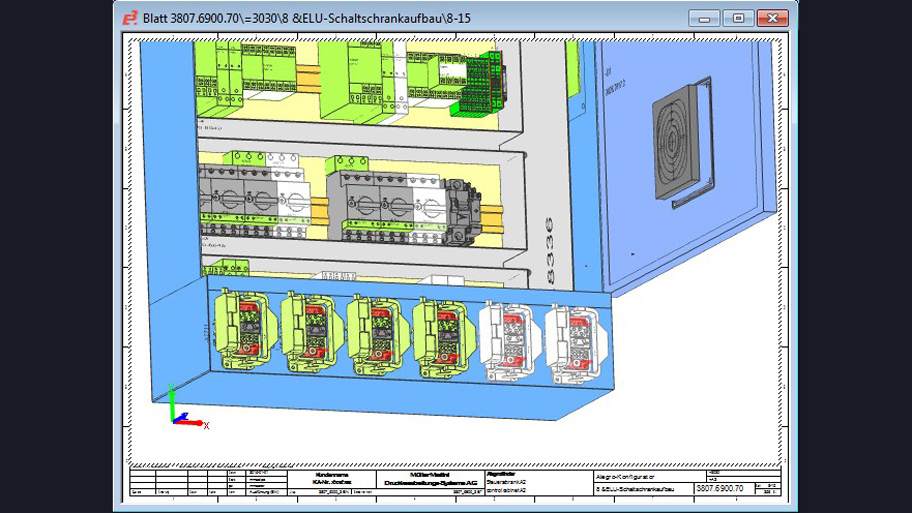

Drilling back panels directly during cabinet production enables a noticeable cost saving in assembly, as no machining is required on the shop floor. “To avoid machining during assembly, we use perforated steel plates, which, however, are more expensive to buy. The objective is to replace costly perforated steel plates by cheaper drilled chassis plates. A prerequisite for this is of course thedirect use of drilling and milling data from E3.series.”

Müller Martini supplies highly flexible, customized print processing machines to the graphics industry. The Swiss-based company recently took the replacement of an end-of-life CAD installation as an opportunity to re-engineer established procedures in electrical engineering and handover to production.

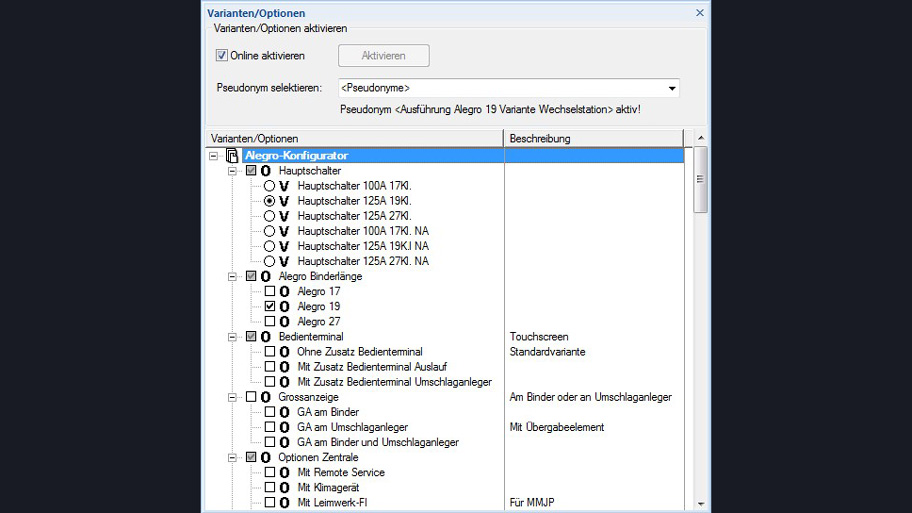

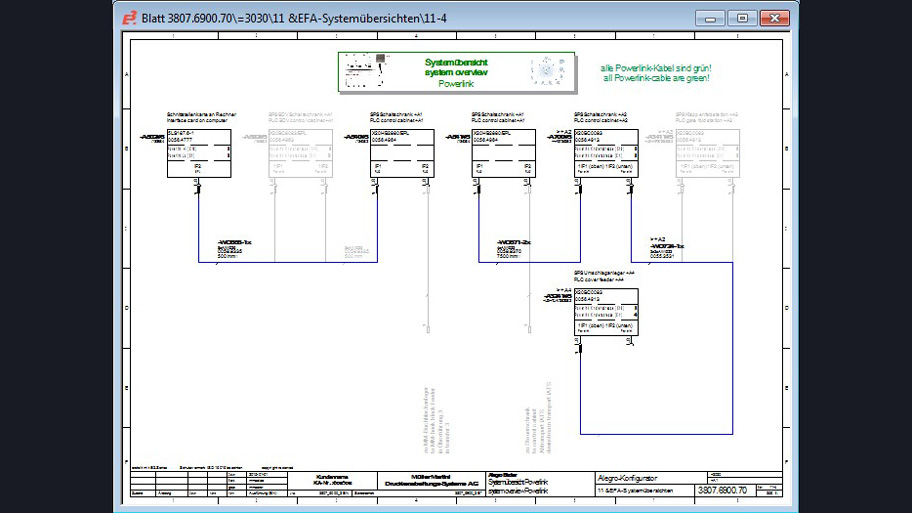

By introducing E3.series, up to 80% off all machine configurations can now be selected from the feature tree of one single E3.series project. They also use E3.series data for NC control in cabinet manufacturing to cut overall manufacturing costs.

Results

Cross section and terminal checks that are now performed during design have already enabled a significant reduction of manufacturing overhead: “Rework because of overpopulated terminals or excessive bundle sizes has decreased significantly.” Other benefits have been achieved through the modelling of cabinets and panels in 3D, as the number of collisions, over populated cable ducts and similar issues, have been significantly reduced. “Increased effort in design enables cheaper and faster production.”

With E3.series, up to 80% of all variants can now be represented in the feature tree of one single project. “We create a 150% over-defined version of every machine in the related E3.series project, from which we then filter the different variants.” Although this method had already been pioneered with Müller Martini’s legacy system, the overhead of managing the different variants was greatly reduced with the adoption of E3.series: “In the past, we used to copy existing projects,creating a new project for every derivative. Now we go the opposite way by filtering different schematics from one single project. The master project remains identical in 80 per cent of all cases, while the remaining 20 per cent are implemented using variants.”

“Our philosophy of customer and solution orientation requires a high degree of flexibility in the engineering workflow. Changes need to be followed through quickly and consistently across all operations. This means we have to constantly find ways to shorten our turnaround times from concept to delivery. And finally we need to harmonize engineering processes across our different lines of business to enable a seamless flow of information between departments, engineering disciplines (mechanical, electrical, software development and assembly) and geographical locations.”

Related products

Discover more about the products that helped Müller Martini