Consumers and businesses alike are demanding smarter products that possess the latest technological capabilities. As a result, new research and continuous advancements in electronic technology continue to progress at a rapid rate. This research focuses the spotlight on one of the most essential components of nearly every electronic device today–printed circuit boards.

The successful launch of new technologies starts and ends with printed circuit boards, or PCBs. As new trends emerge in 2021, both PCB design and manufacturing must adapt to meet the growing needs of our technologically advanced world.

In this post, we’ll cover five of the most noteworthy PCB industry trends this year and the profound impact that will result.

What are PCBs?

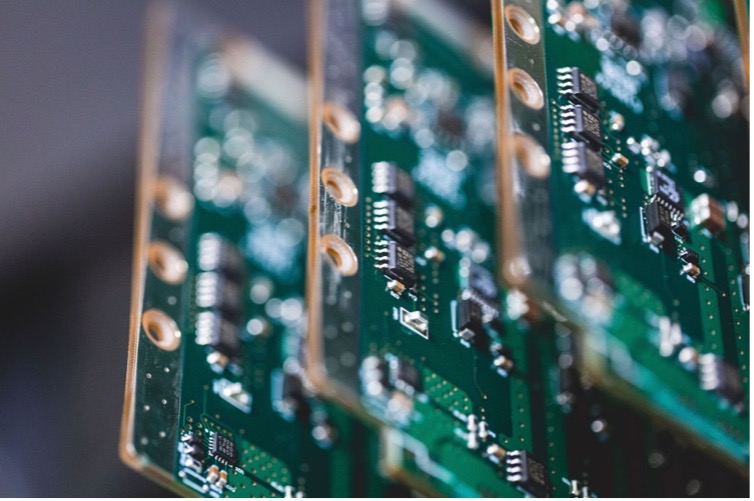

A printed circuit board (PCB) is the interconnect for the operation of anything electronic. These tiny electronic circuits are among the most important elements of technology ever invented.

Visually, a PCB is a flat plate or base of insulating materials that contains a pattern of conducting material and components.

Common Applications of PCBs

Any item that possesses an electronic component will need at least one printed circuit board, which means that PCBs are necessary across nearly every industry. Some of the most common industry applications of PCBs include:

Healthcare

- Scanning equipment: X-Rays, CT scanners, and ultrasounds

- Blood glucose monitors, heart rate monitors, blood pressure monitors

- Research tools: microscopes, control systems, compressors

Industrial

- Manufacturing equipment: electric drills, assembly machines

- Power supplies

- Equipment to measure pressure and temperature

Consumer Electronics

- Communication devices: smartphones, smartwatches, computers, iPads/tablets, laptops

- Entertainment systems: televisions, game consoles, radios, speakers

- Home appliances: refrigerators, dishwashers, microwaves, coffee machines

Automotive

- Navigation systems

- Control systems

- Car sensors

Military Aerospace

- Monitoring and communication equipment

- Power supplies

- Flight systems and hardware

Oil Industry

- Monitoring and downhole sensors

Lighting

- Light-emitting diodes (LEDs)

PCB Industry Trends in 2021

The PCB industry is one of the fastest-growing industries, with experts projecting it to be worth nearly $76 billion by 2025. The latest PCB design and manufacturing trends are consequently changing PCB assembly to better fit our digital era. Here’s a closer look at five PCB industry trends in 2021:

1. High Density Interconnect PCBs

Advancements in automation are happening across nearly every landscape. From aerospace applications and military communications to new improvements in medical diagnostic tools and wearable technology, the demand for HDI PCBs is inevitably rising. High density interconnect (HDI) PCBs provide reliable, high-speed signals. Not only are they smaller in size and lighter in weight than other PCBs, but they also grant a cleaner circuit route with versatile routing options.

HDI PCBs provide smaller trace widths and better wiring density, thus allowing engineers to pack more function and power into a smaller space. They also reduce the need for layering, which in turn lowers the production cost. For these reasons, HDI PCBs are becoming crucial in the latest smart product creations.

2. High Power Boards

The demand for high power boards, especially those with 48V and higher, is increasing significantly. One reason for this is the growing prevalence of electric vehicles, where voltages are often in the hundreds. Similarly, there is higher demand for solar panels, which operate at 24V or 28V.

3. Internet of Things (IoT)

The need for connectivity among all products has driven the demand for IoT in multiple ways. According to Oracle, “The Internet of Things describes the network of physical objects–“things”–that are embedded with sensors, software, and other technologies for the purpose of connecting and exchanging data with other devices and systems over the internet.”

All evidence suggests that it will soon be standard for PCB manufacturing to include IoT components–so what exactly will that entail? To start, any IoT device requires sensors, wireless connectivity, and power. To meet these requirements, the design of PCBs will change in a few ways. For example, new IoT devices such as wearable smartwatches are getting smaller and thus need tinier components that possess the same functionality. Moreover, these devices are also getting smarter, requiring a designer to fit more components into a smaller space than the norm. Similarly, consumers expect new IoT devices to sustain longer battery life, meaning that PCB design must ensure reliable power management.

One hurdle that manufacturers may face is the ability to keep up with the ever-changing rules and regulations that come with the IoT. As our world’s dependence on connectivity continues to increase, implementing proper security among PCBs will be paramount for manufacturers across all industries.

4. Flex PCBs

A single board is responsible for managing several functions, thus making a flexible layout a vital component of PCB functionality. Flex PCBs are smaller and can withstand harsh environments that include everything from simply dropping a cell phone to the complexities of launching a missile. Additionally, they offer enhanced capabilities and better reliability, all while saving space.

Flex PCBs can also handle mode stress and mold into any shape or size. Thus far, their ability to allow smooth attachment of every component has led to advancements in several new medical instruments. Moreover, the innovative materials and characteristics of flex PCBs coupled with the prevalence of the IoT call for a significant increase in the production of flex PCBs.

5. Commercial Off-The-Shelf Solutions

Otherwise known as COTS, commercial off-the-shelf solutions include PCB components, modules, and boards that come “as is.” By design, COTS components are easy to install into existing systems.

Aerospace is an industry where we see PCB technology use COTS prevalently. For example, new space development solutions are implementing PCB COTS to reduce the costs of major initiatives while ensuring quality and safety–all while completing projects faster than ever.

Selecting a PCB Provider

In such a fast-paced world, selecting a PCB solutions provider can feel a bit overwhelming. Therefore, when researching potential companies, it is of the utmost importance to choose a provider that is up to date on the most recent PCB industry trends.

Critical considerations include the provider’s expertise, certifications, and industry experience. Before selecting a provider, be sure to ask the following questions:

- Does the provider have the necessary certifications?

- How many years of experience does the provider have?

- Has the provider ever worked in your industry?

- Does the provider offer a timeline and budget?

- What type of processes does the provider have?

- Does the provider have quality assurance methods?

- Are their employees up to date on training?

- Is the provider capable of working with the newest materials and technologies?

- Does the provider do everything in-house, or do they outsource?

PCB Industry Trends Have a Lasting Impact

PCBs are the heart and soul of nearly every electronic device. These emerging PCB industry trends continue to reach new heights, making a considerable impression on both PCB design and manufacturing. The impacts will range from changes to PCB assembly, arrangement, and composition to an increase in the quantities in demand. As technology grows in sophistication, the PCB industry will have no other option but to meet and even exceed these new complexities.

Related Products & Resources

- Blog

- 2020 Technical Webinars

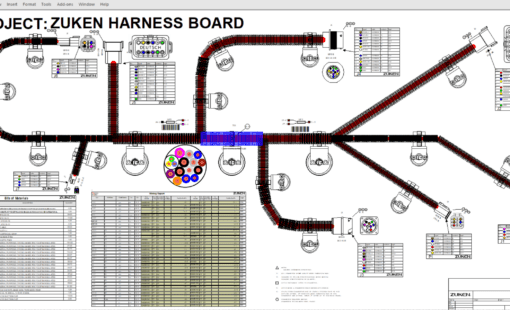

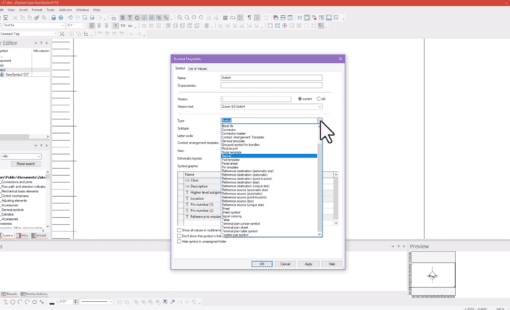

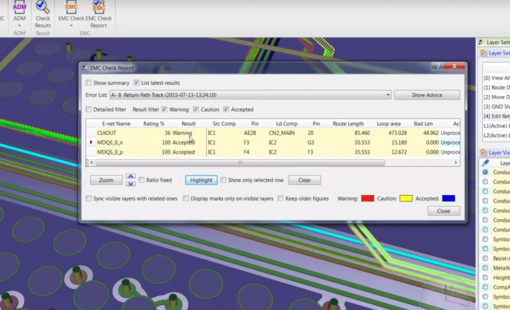

This webinar will explore a high-speed design process in CR-8000 that utilizes a constraint browser, topology template, crosstalk estimation, signal and power integrity simulations.

- Products

- Blog