Sherpa Mobile Robotics is a leading player in the field of autonomous mobile robotics, specializing in the automation of intralogistics flows. With a workforce of 40 employees and a turnover of €3 million in 2023, Sherpa Mobile Robotics is recognized for its innovative solutions.

To address significant challenges in managing the growing number of variations in its robot designs, Sherpa introduced E3.series from Zuken. This move streamlined the design process, enabling Sherpa to reduce the time required to create the electrical designs and production outputs for external wire harness manufacturers.

The Mission: Automating the Flow of Materials on the Shopfloor

Automating the flow of materials on the shop floor with robots that deliver items on trays and containers to order pickers was the vision behind the creation of Sherpa Mobile Robotics, a European designer and manufacturer of autonomous mobile robots (AMR) based in Haguenau, France. Today, Sherpa Mobile Robotics offers a comprehensive range of turnkey solutions to meet the growing demand for efficient intralogistics automation.

To overcome significant challenges in managing the growing number of variations in its robot designs, Sherpa deployed Zuken’s E3.series. This move streamlined the design process, enabling Sherpa to reduce the time required to produce electrical designs and manufacturing outputs for external harness suppliers.

A Comprehensive Range of Autonomous Robots

The Sherpa product portfolio includes a comprehensive range of mobile and fully autonomous robots designed to meet a variety of logistics needs. The range extends from mobile robots for handling small loads such as bins and crates up to 200 kg, to options for medium loads such as dollies and wheeled trays up to 250 kg. For heavier loads, the Sherpa range includes robots capable of handling pallets and crates up to 1200 kg.

Sherpa’s mobile robots are designed to work around the clock, supporting a wide range of use cases in different industries, from warehousing to manufacturing. Their modular design allows them to adapt to different operating environments and integrate seamlessly into existing workflows. In addition, the company offers customised solutions to meet specific integration and customisation requirements, ensuring adaptability to unique operational needs.

The company’s engineering team plays a vital role in ensuring the success of these innovative solutions. From prototyping to development, the team focuses on optimising technical solutions, managing electrical cabling and ensuring smooth industrialisation. This hands-on approach helps Sherpa maintain its competitive edge in the ever-evolving robotics market.

Addressing the complexity of custom harness design

Sherpa’s engineering team faced significant challenges in managing the complex variations in robot designs. Initially, they used Visio to create up to 14 versions of robots with different options and variants, which was both time consuming and costly. Each change required considerable effort and communication between teams, especially when converting designs into production-ready formats.

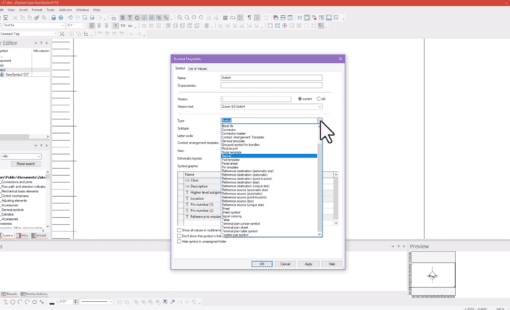

To address these issues, Sherpa migrated to E3.series, a powerful ECAD tool from Zuken. E3.series supports the handling of variant designs through its built-in variant and option management functionality. This feature allows engineers to manage different configurations of a product within a single project, simplifying the design process for products that require multiple variants or options.

In addition to a number of functional advantages over competitive offerings, Sherpa’s engineers benefited from the option to purchase a perpetual licence, which provided them with a more flexible and long-term solution than the rental licence scheme offered by competitors. Combined with a discounted 80-sheet licence option, the E3.series proved to be a cost-effective choice that perfectly matched Sherpa’s requirements.

Cost-effective deployment and operation

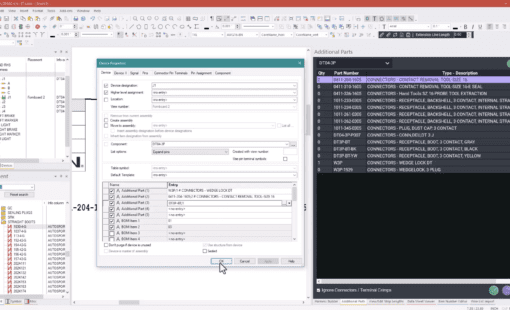

A key factor in selecting Zuken’s offering was the ability to migrate existing designs from legacy formats: E3.series enabled seamless conversion of schematics from third-party ECAD systems, allowing Sherpa to maintain continuity with its subcontractor’s designs. This feature ensured smooth integration into their existing processes. Finally, the modular structure of E3.series provided future-proofing benefits, offering the potential for expansion into areas such as harness design and 3D integration, positioning Sherpa for future growth.

The implementation of E3.series followed a structured process, starting with the evaluation of suitable ECAD offerings. After selecting E3.series, the Sherpa team participated in a 4-day training programme, followed by an extensive testing phase. By April 2024, the team was able to design the electrical schematic for its first robot in just 35 hours – half the time it took using previous methods.

Reduced production time and improved reliability

Thanks to E3.series, Sherpa Mobile Robotics has successfully scaled its operations, reducing production time while improving the reliability of its systems. As a testament to its success, Sherpa’s SHERPA-B robot was showcased at the Zuken Innovation World 2024 event, and the company looks forward to continued growth in the years to come.