Conveyor technology is at the heart of modern manufacturing and logistics. It is a field that has witnessed remarkable growth and innovation, driven by the need for efficiency, precision, and scalability.

Conveyor technology is an instrumental aspect of automating warehouse processes. (Source: Adobe Stock Photos).

In this post, we’ll explore conveyor technology, its significance across various industries, current trends, and how Zuken’s cutting-edge tools are shaping the future of conveyor system design.

Understanding Conveyor Technology

Conveyor systems transport materials, products, or goods from one location to another within a facility. The goal of these systems is to enhance efficiency by reducing manual handling, therefore minimizing errors, and expediting processes. They achieve scalability by providing customization to handle various sizes and types of products, therefore making them adaptable to a variety of industry needs.

There are many different forms of conveyors, including belt, roller, chain, and pneumatic conveyors, each serving specific needs. Due to the dynamic and multifaceted nature of conveyors, developing conveyor technology requires a blend of many engineering disciplines.

Specifically, conveyor design requires mechanical engineering, electrical engineering, and computer science expertise. Engineers in these disciplines collaborate to create a system that integrates motors, sensors, control systems, and software to ensure a seamless flow of materials. The complexity and versatility of these systems mirror the advancements in engineering and technology, highlighting the importance of interdisciplinary collaboration.

Integration of Engineering Disciplines

The design and implementation of conveyor systems exemplify the synergy between various engineering disciplines. Mechanical engineering principles are fundamental in designing the physical aspects of the conveyor, such as structure, rollers, belts, and drive mechanisms. Therefore, engineers need to understand the material properties, dynamics, and mechanical forces at play to ensure durability, efficiency, and safety.

Electrical engineering expertise is crucial for powering the system and controlling the movement of materials. This includes the selection and integration of motors, wiring, and power supply systems. Additionally, electrical engineers work on developing the circuitry for sensors and actuators, which are essential for automating the conveyor’s operations.

Computer science plays a transformative role in modern conveyor system design by integrating software and control systems. This includes the development of algorithms and programming of PLCs (Programmable Logic Controllers) or microcontrollers to manage the conveyor’s operations. Software enables the real-time monitoring and control of the system, facilitating adjustments to speed, direction, and handling procedures based on sensor inputs and operational requirements.

Challenges in Conveyor Technology Development

Developing conveyor technology is not without its challenges. Engineers must address a variety of considerations, including the optimization of material flow, energy efficiency, and system reliability. The choice of conveyor type (belt, roller, chain, or pneumatic) depends on the specific application, including the nature of the materials being transported, the required speed of transport, and environmental factors such as temperature and humidity.

Furthermore, scalability and customization are critical in meeting the diverse needs of different industries. Engineers must design systems that can be easily adapted or expanded, considering future growth or changes in production needs. This requires modular designs and flexible control software to accommodate new functionalities or integrate with other systems.

Trends in Conveyor Technology

As technology continues to evolve, the conveyor industry is adopting new paradigms in its conveyor system design.

An example is the integration of the Internet of Things (IoT). IoT enables real-time monitoring and control through a proliferation of sensors, wireless connectivity, and the use of a centralized control dashboard. In this way, IoT is bestowing conveyors with newfound transparency and operation control.

Computer vision is playing a role in modern conveyor systems. (Source: Adobe Stock Photos).

Additionally, the application of AI and Machine Learning is playing a pivotal role in modern conveyors. Integrating tools like computer vision for object classification and quality control increases the automation and efficiency of conveyor system design. At the same time, AI is helping to optimize conveyor routing, reduce energy consumption, and predict potential failures.

Zuken’s Contribution to Conveyor System Design

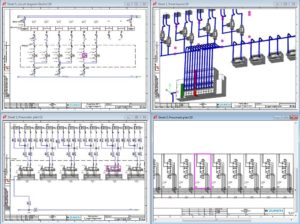

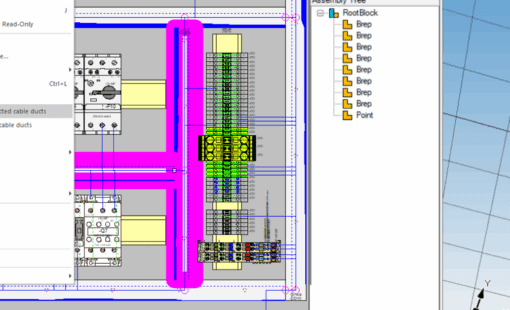

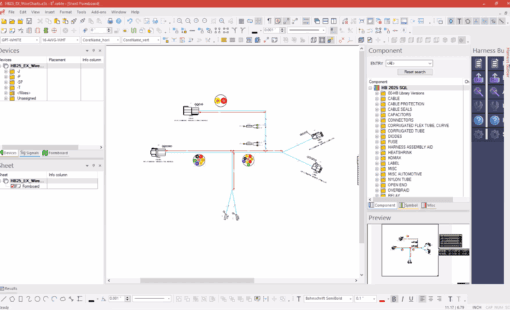

Zuken offers innovative tools like its E3.series software to enable the development of modern conveyor system design.

E3.series is an electrical design software tool that allows engineers to create electrical schematics, control systems, and fluid plans within a unified environment. Notably, E3.series promotes cross-disciplinary collaboration, ensuring that mechanical, electrical, and software engineers work cohesively. By leveraging E3.series, companies can design, test, and implement conveyor systems that are more efficient, reliable, and adaptable to the ever-changing industrial landscape.

Zuken’s tools provide robust simulation capabilities that are crucial for designing conveyor systems. Engineers can use E3.series to test and validate their designs before implementation, identifying potential issues and optimizing performance. This leads to efficient and reliable conveyor system design tailored to specific operational needs.

Additionally, the E3.series offers tools to support the diverse variations of conveyor system design. Beyond electrical tools, Zuken offers E3.fluid, which provides conveyor system designers with a way to create complex pneumatic and hydraulic systems for conveyors.

Zuken aims to empower engineers with vital tools to innovate and adapt, enabling modern conveyor system design and paving the way for the next generation of technology.

Related Products and Resources

- Blog

- Blog

- Blog

- Blog