Maybe you read my blog post last week introducing the concept of DAMA, if not you might want to check it out before reading on.

After introducing the concept last week and talking about it in the PLM context, today I want to focus on other factors such as mergers and acquisitions, information sharing and component obsolescence.

Mergers and acquisitions add to the problem of communication

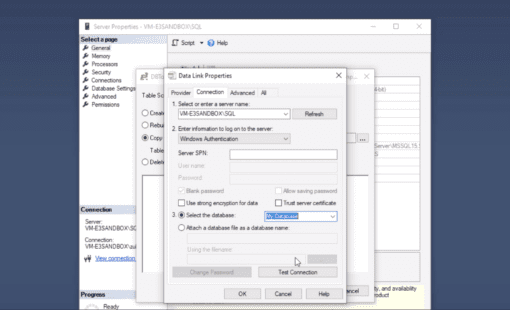

Organizations in a global market are acquiring, merging, and creating partnerships – all of which means that different systems, technologies and processes are being acquired. If you’ve been in an organization that has undergone this process, you have felt the pain and it can be agonizingly frustrating!

Its not rocket science, you and I both know it; integration of these elements is a pre-requisite for effective communications between them.

- The enterprise as a whole therefore needs to be structured in such a way that different systems can be integrated in the shortest possible time and at minimum cost.

- There must be a way to determine how well a product specification maps to each new site, and a way of determining how any new site may contribute to improved manufacturing efficiency, better customer service and, of course, cost reduction.

Again, viewing the enterprise as a whole, the engineering team should ideally ensure that the specification of the product means that it can be developed or manufactured at the site with the most limitations and therefore, by implication, at any other site within the enterprise. A lack of forethought in this area causes a lot of problems.

Maybe someone has suggested moving manufacturing sites to reduce costs after the product has been launched? But using a new site can, for example, lead to increased servicing costs, negating other potential benefits.

Electronic product design and development cannot work in isolation

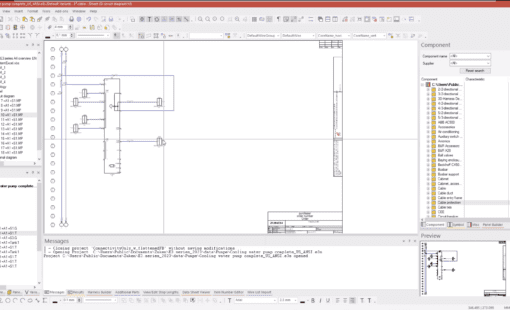

Even at a single site, the whole design and manufacturing process needs to be taken into account at the design phase to avoid problems further down the line. The necessary links between component databases, bills of material, EDA tools, design process management, mechanical design tools and product data are already complex. And to be honest, communications between schematic and layout engineers aren’t always perfect are they? You might still be sitting at adjacent desks and passing scraps of paper to each other.

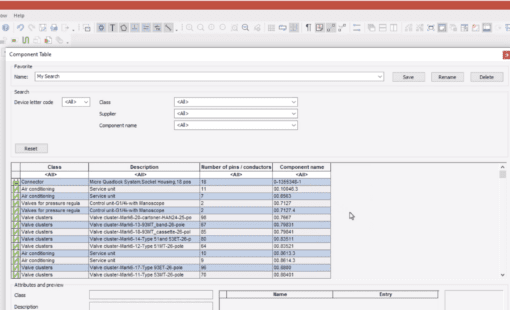

Where multiple sites are involved the complexity of information management needed for a successful product introduction rises exponentially. To take a simple example, a particular component may have the reference ‘4711’ in one location but be called something completely different in another. Clearly, DAMA cannot be achieved if the component is labeled differently at each site, and the same thing applies to manufacturing date. DAMA needs to ensure the ability to exchange design data across sites. One aspect of this is the harmonization of part numbers into a single database that can be accessed from all sites.

So you need a clear change management strategy and an infrastructure to support it, with this in mind you might want to check out DS-2’s (our e-PLM ready solution) change management capabilities:

Component lifecycles and obsolescence

It’s important to remember that individual components have their own lifecycles too, so there is a need to take account of component obsolescence.

In the automotive industry, for example, sub-assembly makers need permission from car makers to change any component and there is a cost-intensive re-certification cycle for each change.

And in any organization, there is the challenge to make sure that throughout the enterprise, everyone who needs it, has access to up-to-date component obsolescence information.

- More information on how Zuken can help you deal with this can be found here http://www.zuken.com/products/ds2/change-mgt/obsolescence-mgt

Next time

In part 3 I’m going to be looking at how enterprise information structures have evolved and the challenges at the engineering and manufacturing level. Again if you want to check out part 1 click here.

Maybe you have a question about DAMA?

Then please get involved, post a comment and I’ll get straight back to you.

Related Products and Resources

- Products

- Products

- Products

The traditional practice of mechanical, electrical and electronic engineers working in silos – then consolidating efforts late in the development process – is no longer viable for successful companies. Zuken offers a portfolio of scalable domain data management solutions for PCB and electrical/fluid design plus a range of solutions that integrate design and domain data management into the PLM and ERP world.

- Products