Companies often introduce new digital engineering methods in two phases. First, organizations must improve the way they develop a system or product definition. Second, they must be rigorous in their product definition for efficient build-out during detailed design. These two efforts are separate but must share a strong connection. This post explores the activities associated with each phase and the roles involved, along with their overlaps.

Digital Engineering Methods: Systems Engineering

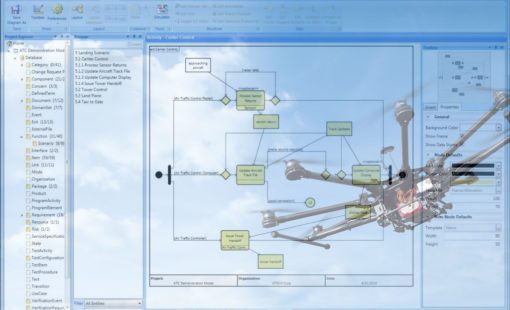

A sound model development plan needs to cover much ground while appropriately documenting critical details for further development. First, engineers need to define requirements for the product. Then they must use those requirements to determine functions, logical architectures, and physical architectures. The plan needs to include the development and implementation of simulations for different aspects of the product. Where applicable, it must also provide information about how to run trade studies to determine the best-proposed architecture.

But that’s not all. There are many other aspects of a system model to consider and then build out. Among these are use cases, interfaces between subsystems, and risks. Ultimately, organizations must determine which requirements and constraints to pass to the detailed design teams for further refinement.

Certainly, at this stage of product development, systems engineers can work somewhat independently of the detailed design team. Developing a comprehensive systems model is complex work–and requires a fair bit of expertise to do it well. Systems engineers also likely rely on specialized tools. These help them develop the model’s details in a way that allows appropriate traceability given the complexity. A foundational concept of digital engineering is the replacement of documents with models. The product definition is stored as a model built on a relational database. The hand-off to detailed design is extracting the relevant piece of the model for the assigned team. For instance, take a vehicle model with five electronic control units (ECUs). The detailed design team can begin their work after handing off the assigned ECU and design envelope.

Digital Engineering Methods: Detailed Design

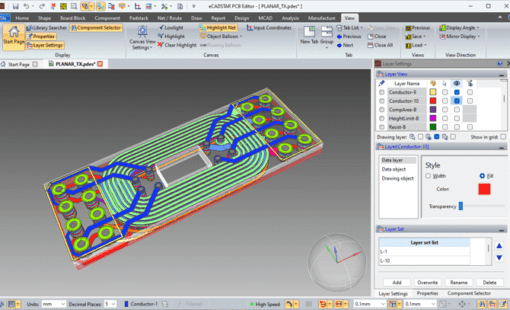

Executing a detailed design is just as complex as creating a viable product model. This is where engineers develop any aspect of the product digitally associated with the systems and subsystems. Detailed design engineers will provide digital definitions. These can include models, drawings, diagrams, and schematics of the mechanical hardware, electrical systems, electronic systems, and software. They may also have text-based definitions like specifications, failure mode and effects analysis (FMEA), and other documents. The digital definition also covers analyses and simulations to verify and validate behaviors, performance, and requirements satisfaction.

Engineering organizations may structure the work in this stage in a variety of ways. Some companies may divide engineers into domain-specific teams. For example, one team may focus purely on mechanical hardware, while a second team handles software development. Other organizations may prefer cross-functional teams made up of engineers from different domains. These may tackle a specific subsystem, like a battery platform, assisted/autonomous driving system, or other complex product component.

Connecting the Two

Developing a product model and executing a detailed design are two separate phases responsible for different deliverables. However, there is a strong connection between the two. In the detailed design phase, engineers must verify the product architecture before the systems planning phase is complete. This is a vital step. It ensures that the system plan is feasible before investing additional time and resources.

In addition, systems engineers don’t abandon product development once they define the architecture. They need to follow the progress of the detailed design. Then they use that detailed definition to verify the product’s performance, behavior, and requirements satisfaction at a higher level. Ultimately, this provides all stakeholders with the knowledge that their work will yield a successful system. It also eliminates expensive and time-consuming surprises once the project progresses to prototyping and testing phases.

Digital engineering methods can tie these two essential phases together. Then both systems engineers and detailed design engineers will be in a better position to define complex products more efficiently. They can also develop a feasible design that will meet all product requirements from the get-go.

Summary

Digital engineering supports engineers as they design today’s smart products.

Systems engineers often work in a relative silo while developing the systems plan. Even so, their decisions affect the entire product development process. This is particularly true of the detailed design team, which must take the defined architecture of a product and then detail its specific subsystems and components. When organizations connect these two vital phases using digital engineering tools and processes, everyone benefits. That collaboration allows the engineering team, regardless of their structure, to more easily define and then verify feasible designs—and helps ensure that what they ultimately create will be successful.

—–

For more information about digital engineering, architecture-driven engineering, and model-based engineering, visit our website or download our Digital Engineering eBook.

- Blog

- White Paper

This eBook describes an MBSE based process for Electrical and Electronic design. The eBook begins with model content and structure with the purpose of implementation and the need for a “design envelope”.

- Webinar

- Blog