Bridging the Gap Between Design and Manufacturing for Peak Collaboration

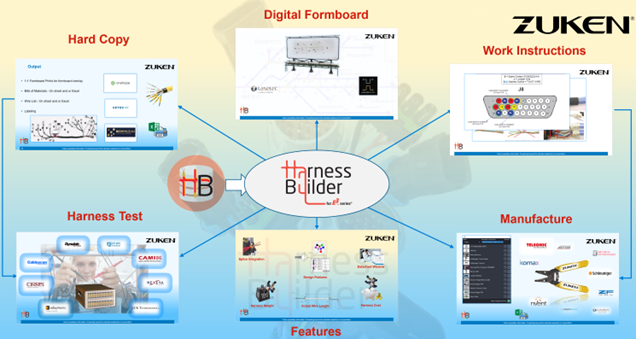

Seamless collaboration between design and manufacturing teams is critical when working with the detailed wire harness projects you encounter today. This post explores strategies to bridge this gap, including standardizing project consumption, automating processes, integrating feedback mechanisms, and conflict resolution. Additionally, we will cover two Zuken tools that will help to facilitate this collaboration, Harness Builder for E3.series and E3.HarnessAnalyzer.

Standardize Project Consumption

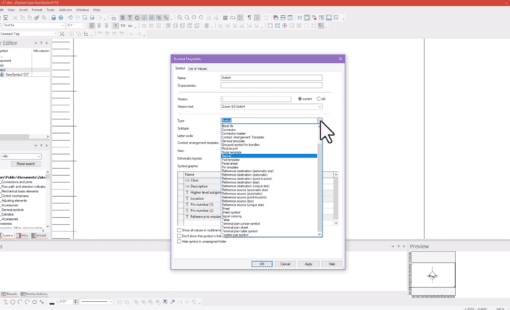

Ensuring that all users consume projects consistently is the cornerstone of effective collaboration. Therefore, we create a common language that minimizes miscommunication by standardizing how design and manufacturing teams interpret project data. We can achieve this by implementing robust data management systems that align both teams on a unified workflow. A shared platform where all relevant information is accessible in the same format ensures everyone is on the same page from the project’s outset.

Automate Wire Cut, Mark, and Strip Machines

One of the bottlenecks in wire harness manufacturing is the manual entry of data into wire-cut, mark, and strip machines and testers. By eliminating this manual process and integrating automated systems, teams can reduce errors, save time, and enhance productivity. Automation not only streamlines manufacturing but also ensures that real-time updates from the design phase instantly reflect any changes across all stages of production. Harness Builder for E3.series offers automated outputs for all your manufacturing needs.

Implement Early and Frequent Feedback Loops

Incorporating early and frequent feedback is vital for catching potential issues before they escalate into significant problems. Furthermore, regular check-ins and iterative reviews between design and manufacturing teams can drastically improve the final product’s quality. Feedback loops facilitate a culture of continuous improvement, where both teams can refine their processes and output based on real-time data and insights.

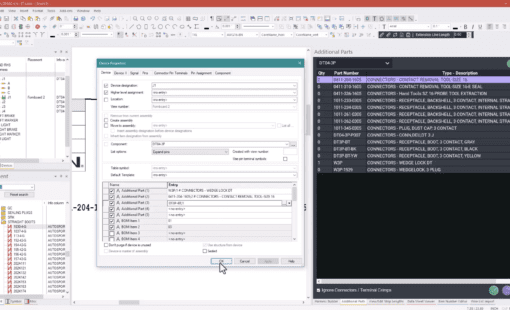

Leverage E3.HarnessAnalyzer for Transparent Conflict Resolution

Conflicts and discrepancies between design and manufacturing can lead to costly delays. E3.HarnessAnalyzer offers a transparent solution for efficiently resolving these conflicts. By providing a detailed analysis of the wire harness design, it identifies potential issues that could arise during manufacturing, allowing teams to address them proactively. This tool promotes a collaborative environment where both design and manufacturing can make informed decisions backed by data. By being the central tool where users can consume all harness data, it enhances this collaborative environment.

Improving Collaboration Between Design and Manufacturing

Enhancing collaboration between design and manufacturing teams in wire harness projects requires a multifaceted approach. This approach involves standardizing project consumption, automating key processes, fostering a feedback culture, and utilizing advanced tools like Harness Builder for E3.series and E3.HarnessAnalyzer. These measures help organizations streamline their workflows and improve their output quality. As the industry continues to evolve, embracing these strategies will be crucial for staying ahead in the competitive landscape of wire harness manufacturing.

Ready to enhance your wire harness project management? Learn more about our solutions and start optimizing your processes today!

Related Products and Resources

- Blog

- Blog

- Blog

- Blog