Each new generation of automobiles has an increasing number of electronic systems that require communications with other vehicle systems at ever-higher speeds. The proliferation of advanced driver assistance systems (ADAS) with fully autonomous vehicles on the horizon has greatly increased the amount of bandwidth that must be transferred between the many processors, cameras, radar units, display head units, etc. on current and next-generation vehicles. Today’s high-end vehicles have 70 or more electronic control units (ECUs) that implement hundreds of distributed functions including bandwidth-intensive applications such as collision lane departure warning systems, collision avoidance systems, and automatic high-beam switching.

Wire harnesses account for 50% of vehicle labor

A patchwork of networking protocols is currently used for in-vehicle communications with most of these systems being originally developed for the needs of one class of applications, each with its own dedicated wiring and communications requirements. Today’s vehicles typically run many of these protocols, including CAN, FlexRay, MOST, and LVDS, that is only in rare cases able to communicate with each other. The result is that most of these vehicle systems have their own dedicated networking system and wiring that must be interconnected through a complex wiring harness. According to one industry player, wiring harnesses are the third highest cost component in a vehicle (behind the engine and chassis) and comprise 50% of the labor for the vehicle. Two additional problems with the heterogeneous approach are that current networking technologies are running out of bandwidth and support for multiple networking technologies adds to design costs and complexity.

Ethernet to the rescue

As vehicles transition to higher levels of autonomous driving, networking requirements are growing at a rapid rate. The top contender to meet these requirements is the ubiquitous Ethernet protocol which has already established a dominant position in most other industries. The lowest speed Ethernet standard of 100 Mbps is much faster than any traditional automotive networking system and Ethernet offers a proven upgrade path to much higher levels of bandwidth. The wide availability of Ethernet intellectual property and chips make it relatively easy to connect existing networking systems to Ethernet in the short run and to enable applications to communicate natively with Ethernet in the future. A key advantage of the Ethernet is the potential for replacing the wiring harness with a single twisted pair, resulting in substantial reductions in weight and labor expenses.

BMW was the first automaker to use Ethernet in a production vehicle. Its X5 model uses Ethernet to connect cameras to the optional surround-view system electronic control unit. Ethernet is used in the infotainment network of the Jaguar Land Rover XJ. The Volkswagen Passat uses Ethernet for its park assist parallel parking system, the first Ethernet implementation on a mass-market vehicle. A few other manufacturers use Ethernet to connect rear vision cameras to the car’s infotainment system. The move towards automotive Ethernet has been aided by the release of the IEEE 802.3bw standard for 100 Mbps Ethernet which exists in the same ecosystem as other Ethernet specs, providing access to existing components and intellectual property. The IEEE 802.3bp standard for 1000 Mbps automotive Ethernet has been completed and products are expected to appear late in 2017. Research firm Frost and Sullivan expect the number of Ethernet nodes to take off from here, rising to 50 to 60 in mass-market cars by 2020.

Smarter, safer vehicles

“Automobiles are undergoing the biggest disruption in the past one hundred years, with a push towards autonomous driving capabilities that are poised to revolutionize our lives,” said Claude Gauthier, Chief Technology Officer of OmniPhy, a supplier of automotive Ethernet IP. “Autonomous cars require a major increase in internal connectivity and Ethernet is well equipped to deliver the required bandwidth. For example, sensors used to scan the vehicle’s environment generate an enormous amount of data that must be delivered to image processors in time to detect a kid on a skateboard in the vehicle’s path and apply the brakes. Ethernet provides the glue that will tie these sensors and processors together at much higher speeds while reducing size, weight, and cost, enabling vehicles to become smarter and safer than the current generation.

Related Products

- Products

- Products

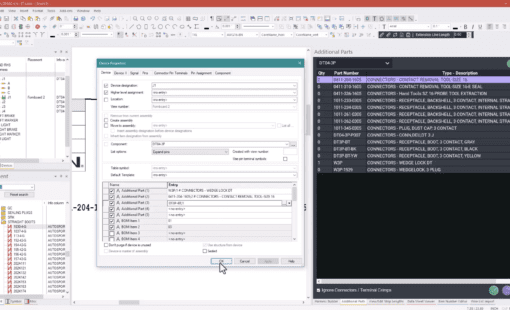

E3.series is a Windows-based, scalable, easy-to-learn system for the design of wiring and control systems, hydraulics and pneumatics. The out-of-the-box solution includes schematic (for circuit and fluid diagrams), cable (for advanced electrical and fluid design), panel (for cabinet and panel layout), and formboard (for 1:1 wiring harness manufacturing drawings). Integrated with MCAD, E3.series is a complete design engineering solution from concept through physical realization and manufacturing output.