Wire harness design and manufacturing require precision, adaptability, and a commitment to continuous improvement. The new features in Harness Builder 2025 for E3.series make these goals easier to achieve, offering tools that reduce manual work, enhance accuracy, and integrate seamlessly with manufacturing equipment and ERP systems.

Whether you’re designing simple harnesses or managing complex projects, these updates bring a combination of efficiency and innovation to your workflows. Let’s explore the enhancements shaping the future of wire harness design.

How Harness Builder Enhancements Are Developed

Each year, the development team behind Harness Builder works closely with customers and applications engineers to identify the most impactful improvements. By listening to feedback, analyzing user needs, and collaborating with key industry players, they create updates tailored to real-world demands.

For 2025, the team put the focus on improving compatibility with external systems, streamlining user workflows, and adding automation features to save time and improve design accuracy. The result is a robust toolset designed to support engineers, manufacturing professionals, and managers alike.

Key Enhancements in Harness Builder 2025

Seamless Integration with New Equipment

The 2025 release expands its compatibility with essential manufacturing tools, enabling direct communication and data transfer to reduce setup time and errors.

- adaptronic Tester: This integration simplifies the testing process by generating DAT XML reports with all required configuration details. Users can ensure accurate testing setups for every harness, reducing rework and errors.

- Telsonic Welding Machine: Automate ultrasonic welding processes by exporting splice data directly to Telsonic machines. The new tool provides flexible configuration options, allowing users to define job IDs, product quantities, and more.

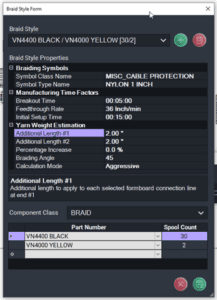

- OMA Braiding Machine: A standout enhancement, this feature allows users to configure braiding specifications such as spool quantities, braiding angles, and start/end lengths. The system calculates costs and materials automatically, making it easy to integrate braiding into your harness designs.

Enhanced ERP Compatibility

Harness Builder 2025 introduces integration with the Berrylium ERP system. Users can now send PDFs and BOMs directly through an API, streamlining workflows between engineering and manufacturing teams. Customers can also request support for additional ERP systems, such as Sage or Epicor, ensuring their specific requirements are met.

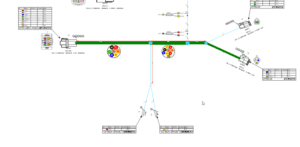

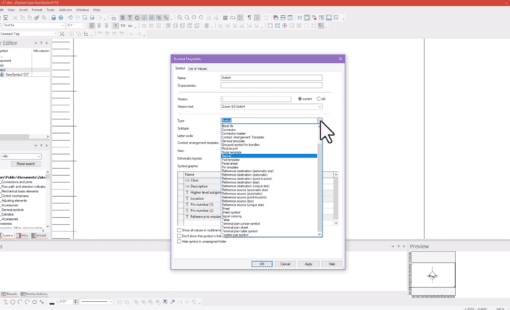

Improved Formboard Copilot for Precision Design

Designing formboards is now more intuitive with the updated Formboard Copilot interface. Engineers can specify exact segment lengths and angles during the initial layout, reducing the need for manual adjustments later. This enhancement makes it easier to create accurate backbones and modify layouts as needed.

Notable features include:

- Direct input for segment lengths and angles.

- Visual tracking of remaining segment lengths.

- Retention of freehand placement functionality for users who prefer manual adjustments.

Dynamic Segment Thickness Adjustment

Keeping track of segment thickness has never been easier. Harness Builder 2025 automatically adjusts the displayed thickness of segments based on the number and gauge of wires added or removed. This feature provides real-time feedback, ensuring that designs reflect accurate dimensions for manufacturing.

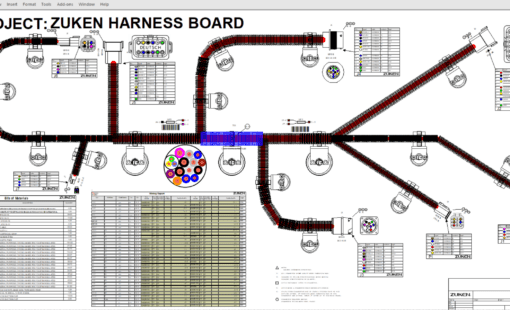

Automatic Wire Chart Placement

Placing wire charts on formboards used to require manual selection and positioning for each connector. With the new automatic placement feature, you can place wire charts instantly for all connectors, saving time and ensuring consistency.

Users can customize table placement with settings for offsets, table styles, and more. You’ll find this feature especially useful for large harnesses, where manual table placement could be time-consuming.

Advanced Reporting and Export Options

Documentation and data sharing are vital for successful wire harness projects. Harness Builder 2025 introduces powerful new reporting features:

- CSV Exports: Generate BOMs and wireless reports in CSV format for easy import into ERP systems or analysis in Excel.

- Options and Variants Support: Reports now reflect selected design options and variants, ensuring accurate documentation for multiple harness configurations.

Customer-Driven Customization

Customer collaboration remains a cornerstone of Harness Builder’s development. For example, we added the Onshape-specific wireless export profile in response to user requests. Similarly, users can submit enhancement requests to add support for new equipment, ERP systems, or export formats. The development team works closely with customers and machine manufacturers to ensure that integrations are reliable and tailored to real-world needs.

Harnessing the Future of Design

Harness Builder 2025 delivers a comprehensive suite of updates to enhance wire harness design and manufacturing. From seamless equipment integrations to improved automation and dynamic reporting, these features empower engineers and manufacturers to work smarter and faster.

As the demands of modern manufacturing continue to evolve, Harness Builder stays ahead by providing tools that address real-world challenges. Whether you’re looking to improve efficiency, reduce errors, or simplify complex workflows, the 2025 release has something for everyone.

Connect with me to share your thoughts and ideas for future releases.

Related Products and Resources

- Blog

- Blog

- Blog

- Blog