When discussing industrial technology, two buzzwords frequently emerge as transformative elements in smart manufacturing: 5G and the Internet of Things (IoT). These technologies are reshaping manufacturing processes and redefining the way industries operate. This post explores how 5G and IoT are instrumental in this transformation and how Zuken’s E3.series leads the charge.

Technological Impact of 5G and IoT in Smart Manufacturing

The integration of 5G and IoT technologies marks a significant milestone in the journey towards advanced smart manufacturing. 5G, known for its high speed, low latency, and widespread device connectivity, is critical for real-time data transmission and processing. This capability is vital in manufacturing settings where split-second decisions and actions significantly impact production efficiency and safety.

IoT brings a different dimension to the table. It encompasses a network of interconnected devices, each with capabilities to collect, transmit, and receive data. In the context of manufacturing, this means that every sensor, machine, and device is a source of critical data. Once analyzed and applied, this data can help optimize production processes, predictive maintenance, and enhance quality control.

Together, 5G and IoT facilitate a more interconnected and intelligent manufacturing environment. They enable the development of digital twins—virtual replicas of physical assets, processes, or systems—all of which can be used for simulation and analysis. This synergy enhances operational efficiency, reduces downtime, and drives innovation in product development.

Continuous data collection, including parameters such as temperature, pressure, vibration, and production speed, enables a manufacturing plant to implement predictive maintenance. This approach, driven by real-time data analysis, allows the maintenance team to identify potential equipment failures before they occur. As a result, there is increased stability in production efficiency and reduced unplanned downtime. An example of this could involve rises in vibration or abnormal temperature readings, indicating wear and tear and prompting proactive maintenance measures.

The Role of E3.series

Zuken’s E3.series offers several robust tools and features that help support the transformation of smart manufacturing.

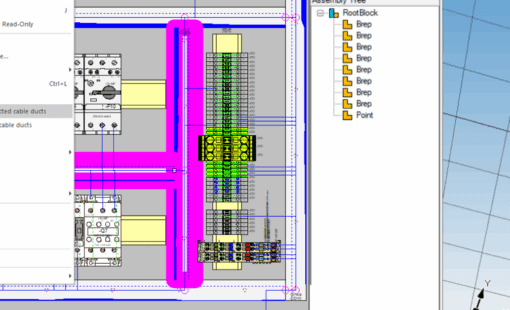

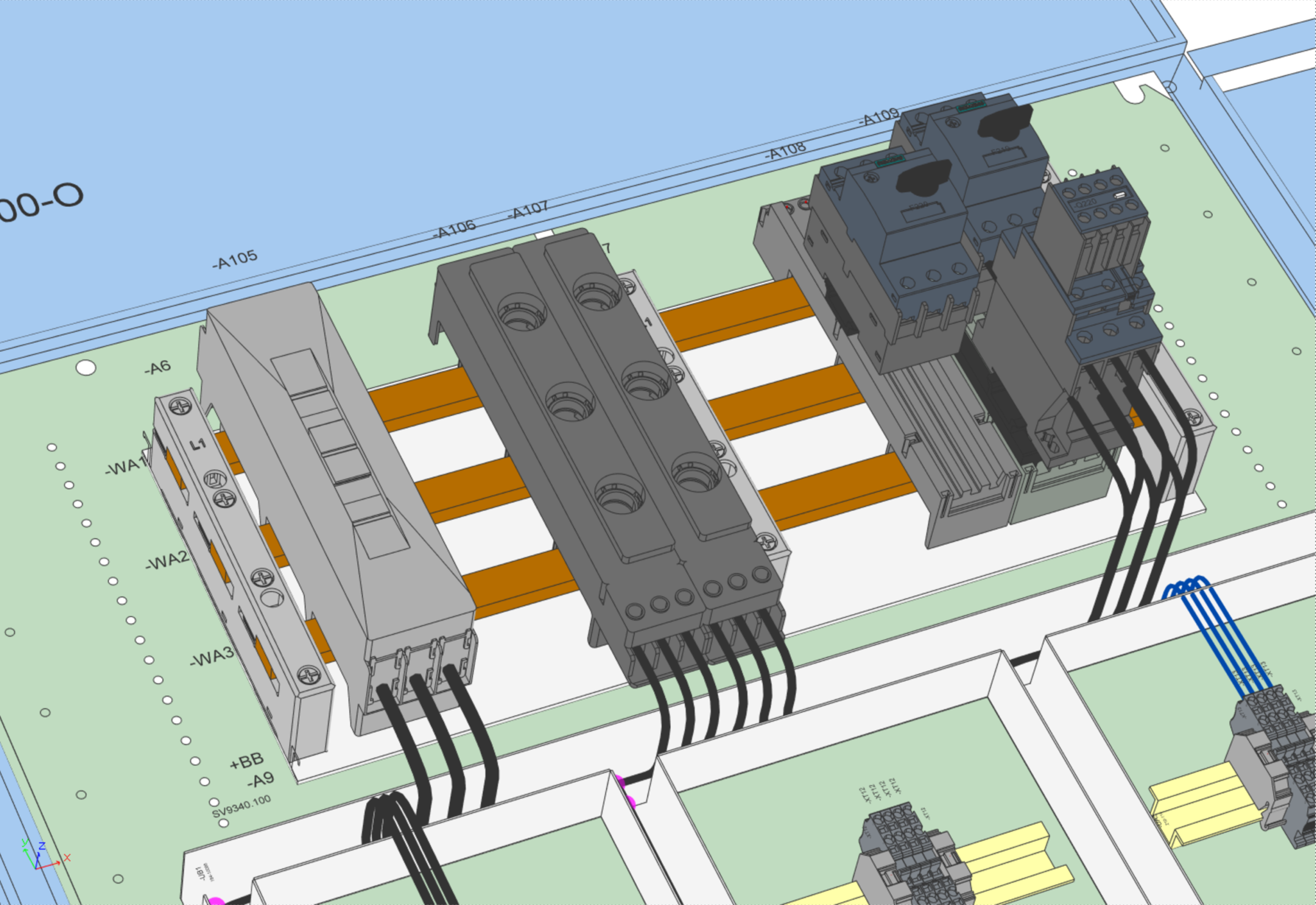

For example, E3.series is specifically designed to optimize the digital twin creation process, a key component in smart manufacturing. The software focuses on improving this process and simplifying the adoption of smart manufacturing technologies. Particularly, recent enhancements in cabinet design, 3D visualization, cabling, and wire harness detailing in E3.series bring users closer to achieving a true digital twin. These enhancements are essential, enabling design teams to create digital twins entailing detailed functional and manufacturing aspects—all within one comprehensive tool suite.

Furthermore, E3.series offers specific add-ons that facilitate digital wiring, quality control, and tracking—all critical components in smart manufacturing solutions. These add-ons are particularly relevant in the context of 5G and IoT, as these technologies rely heavily on efficient and precise control and monitoring systems.

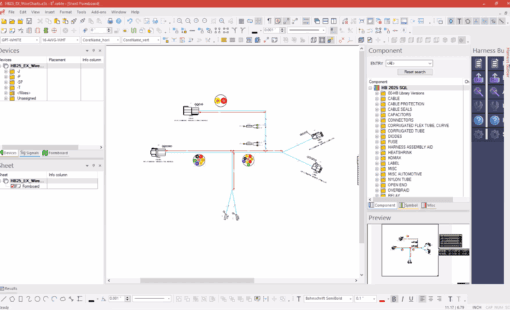

Additionally, Harness Builder for E3.series introduces enhancements that accelerate the adoption of smart manufacturing. These include improvements in wire harness cost and weight estimates, and the ability to connect to leading third-party testing and manufacturing solutions. This integration with external solutions and emphasis on wire harness optimization underlines the E3.series’ role in streamlining manufacturing processes essential for 5G and IoT-driven environments.

Zuken Leads the Way

The convergence of 5G and IoT technologies is undeniably revolutionizing smart manufacturing and pushing the boundaries of possibility in industrial production. The integration of these technologies results in enhanced connectivity, improved efficiency, and innovative solutions. In this dynamic environment, tools like Zuken’s E3.series play a pivotal role in enabling manufacturers to fully leverage the potential of 5G and IoT, driving the future of smart manufacturing.

Related Products and Resources

- Products

E3.series is a Windows-based, scalable, easy-to-learn system for the design of wiring and control systems, hydraulics and pneumatics. The out-of-the-box solution includes schematic (for circuit and fluid diagrams), cable (for advanced electrical and fluid design), panel (for cabinet and panel layout), and formboard (for 1:1 wiring harness manufacturing drawings). Integrated with MCAD, E3.series is a complete design engineering solution from concept through physical realization and manufacturing output.

- White Paper

- Blog