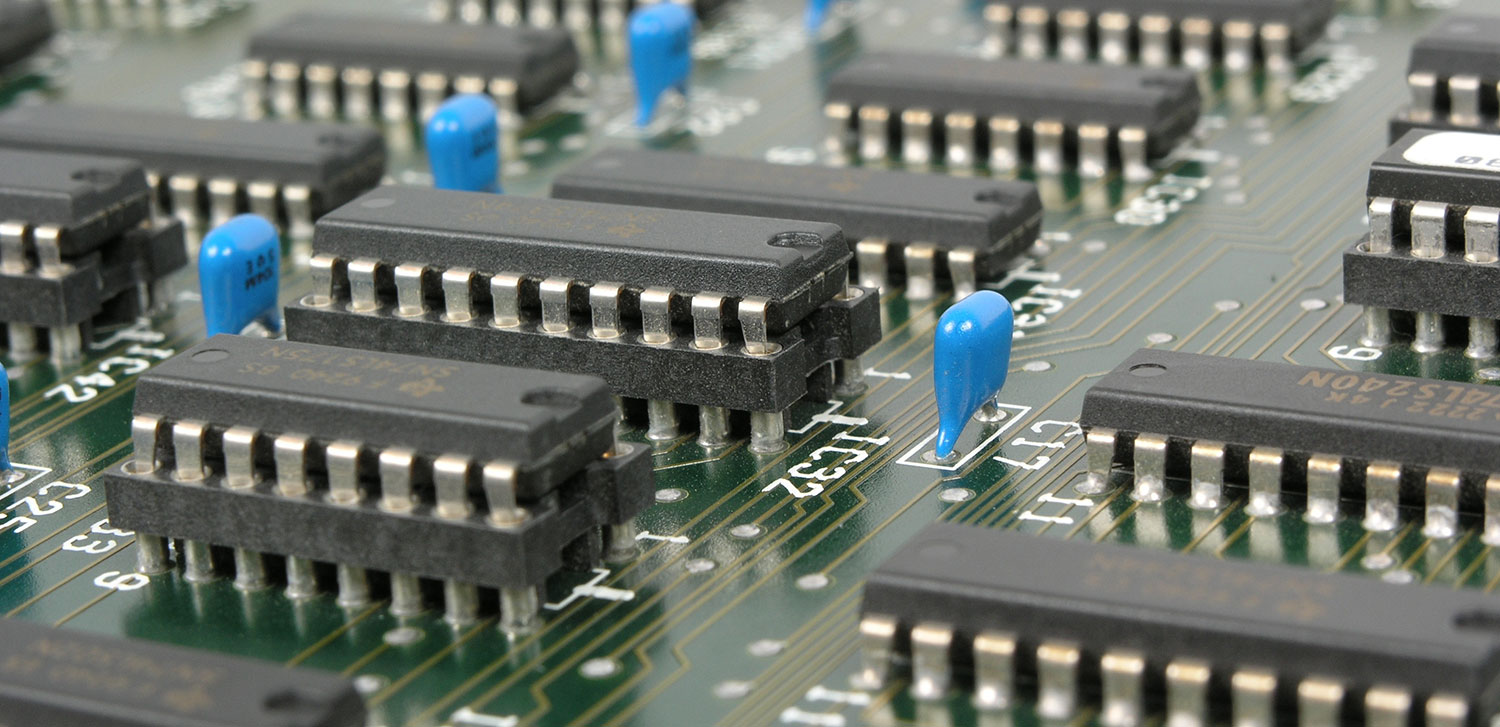

You could pick up any PCB or electronics design magazine and probably at least one article will be devoted to some aspect of high-speed digital design; be it routing techniques, signal integrity analysis, electromagnetic compatibility or power integrity. This has now become a mainstream design practice.

Being able to achieve successful designs repeatedly suggests that a honed process is in place – one that captures electrical intent, enables design realization, and promotes verification, to ensure that the product delivered matches the requirements and specifications. However, as you well know, having in place such a formal process is often more an ideal than a reality.

Realizing products with significant high-speed digital content requires you as the electrical engineer/PCB designer to operate in different specialties. Besides performing circuit design, the engineer needs to evaluate the design’s signal integrity, apply mitigation techniques, and all while keeping in mind the physical limitations of the board. The time he or she can devote to such activities is usually a fraction of the overall design time, with the majority being spent on researching parts, attending design reviews, testing the design in the lab, and participating in numerous meetings. This also usually means that an in-depth, post-layout analysis of the product is compromised.

So what can be done to improve the situation? Well lots, and during these couple of blog posts, I’m going to look at the role of both the engineer and PCB designer, consider the traditional design process, and make suggestions on how you the designer can contribute significantly to improving a design’s overall signal integrity while simultaneously saving time so that the engineer can focus on more in-depth issues.

Putting Signal Integrity (SI Analysis) into context

You know this, but let me just explain some more…as a PCB designer, you work closely with the engineer who also works under a tight schedule (and they remind us enough don’t they?). The designer’s role is to physically realize the design as outlined by the engineer vis-à-vis constraints as quickly as is possible. Because the engineer often has to manage a constant stream of changes, in turn you have to be patient and implement these at whatever point in the design process they are required. Traditionally, the main urgency to complete the layout is to obtain a prototype so that the engineer can test the product in the lab – getting to this stage is often set as a design process milestone. However, gaining access to probe signals in today’s high-speed designs can be difficult, due to component packaging.

One option to help mitigate this issue is to have a signal integrity (SI) analysis tool in the design environment. Yet, having access to an SI analysis tool versus implementing the practice of SI analysis as part of the design process are two entirely different states. Further, performing SI analysis has been perceived historically as a black art, requiring specialist knowledge and skill set. Some companies even have an entire group dedicated to performing this task – are you one of those lucky ones? The traditional design schedule does not promote this activity and to incorporate it now into the schedule does not remove the need for examining the product in the lab. Consequently, the perception could be that adding SI analysis to the design process gives the electrical engineer another job to do, in addition to their already long list of actions. But this can be perceived as a somewhat limited view as the benefits of addressing signal integrity up front can be vast, both in time and money savings – enabling the design team to deliver boards that are going to be right-first-time.

PCB designer – best positioned to resolve SI issues early

So this is my very biased point of view: the PCB designer is best placed to solve these SI issues early. In traditional-style development organizations, the engineer does not look at SI issues until the board is completely placed and routed. Any issues the engineer finds are flagged and sent back to you the designer. In order to complete the design, several iterations of this SI review cycle may occur – and what a waste of time this really is. However, if the design environment includes a PCB design tool that incorporates constraint management with the ability to analyze signal integrity, as in the case of our CR-5000 Lightning Realize solution, the PCB designer becomes the person best positioned to improve a design from a high-speed design standpoint; as part of the layout process, you can perform first-pass signal integrity checking. Through this SI screening, you can make the design process more efficient by greatly reducing the number SI review cycles, thereby saving time and money Ah ha, who’s in control now

The advanced capabilities of today’s design tools that are available to the PCB designer mean that in one application, the designer can realize the placement and routing as guided by physical and electrical rules (constraints) and then screen for crosstalk and signal quality without needing a deep understanding of electrical theory. Solutions such as CR-5000 Lightning are so sophisticated that you as the designer can effectively resolve some lesser issues that were once only solvable by the engineer, therefore reducing the number of actions on the engineer’s to-do list (now there’s a good way of getting them on your side).

I’ve been told not to promote products on the blog, but I can’t avoid including a bit. As CR-5000 Lightning is such a powerful environment, you are able to perform signal integrity screening as a fluid part of the PCB design process. Issues are presented in a spreadsheet alongside corresponding constraints, and crosstalk hotspots can be highlighted on the PCB design canvas. You can then resolve these issues by manual or automated means.

In this preliminary look at signal integrity, there is no need to involve the engineer, thereby saving the engineer time that can be used to look at more significant SI issues later in the design cycle.

Has this whet your appetite enough? Go straight to the final post on this topic that explains the guidelines you should follow as a PCB designer.

Oh and if you would like some help with your Signal Integrity Processes, check out the services we currently offer in this area.

Related Products and Resources

- Products

Today’s Desktop PCB Design tools require better connectivity to the outside world. eCADSTAR offers a newer level of connectivity that brings users closer to their parts providers than ever before. This allows Engineers to selected parts and drag them directly to their design. Add the additional functionality of high power Signal integrity verification and Power integrity analysis and you have the Ultimate Desktop PCB Engineering solution.

- Products

- Products

Building a competitive product today is much more difficult than a few years ago. Existing PCB-centric design processes are limited to a single PCB and do not provide the necessary tools for today’s competitive product development environment. PCB-centric design processes are falling behind.