Digital Engineering simply stated is the move from a document-driven design process to a model-based engineering process. The Department of Defense (DOD) is a leader and advocate for this methodology. The U.S. Army utilizes digital engineering for the next generation of the Bradley combat vehicle. But what about the commercial market? During our recent Digital Engineering Basics webinar series, we polled the audience about their journey to Digital Engineering. Surprisingly, more than 50% of the respondents were in research mode. However, only 8% were in deployment, and many of those were DOD suppliers. The model-based engineering process apparently has a problem.

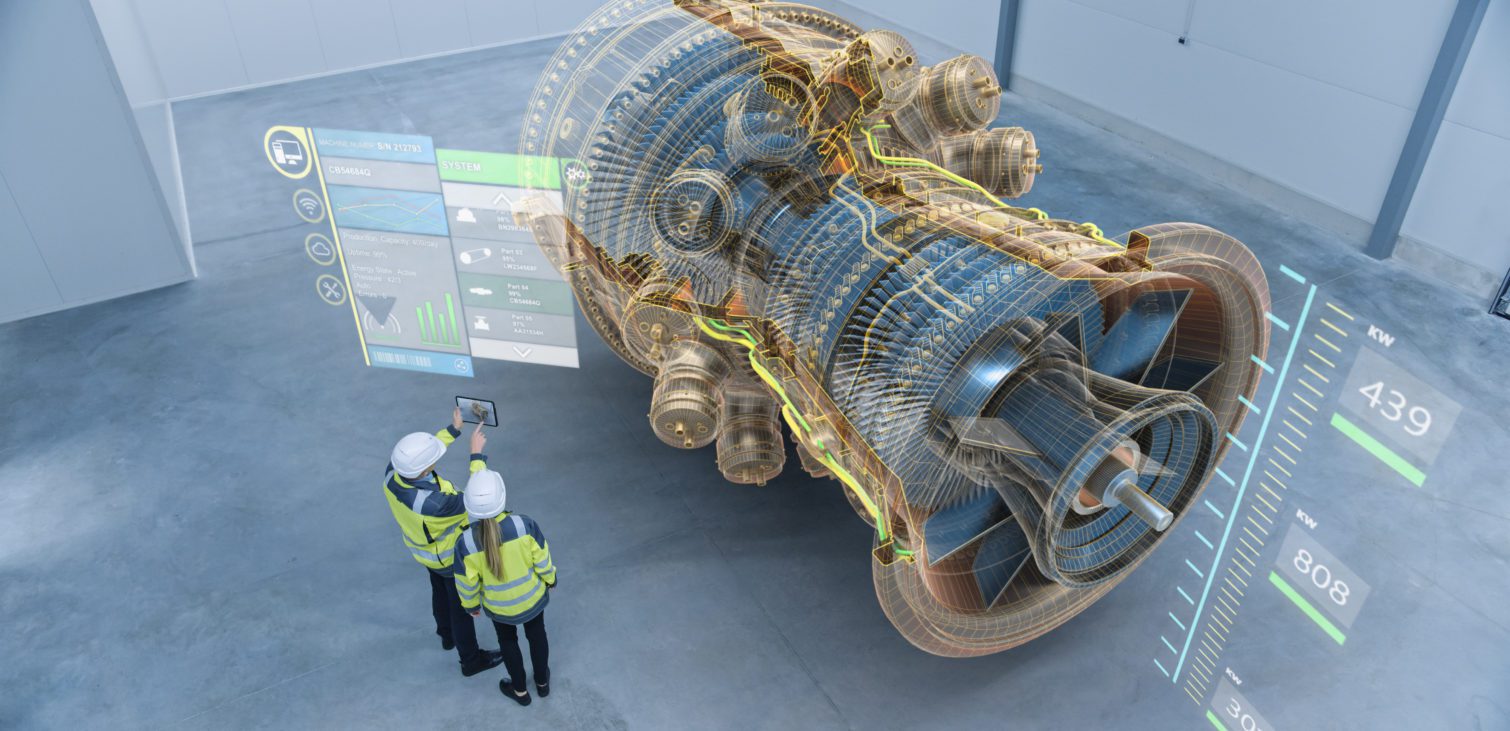

But why all the interest in digital engineering and a model-based engineering process? The most common reason for digital engineering adoption is product complexity. Not surprisingly, document-driven processes can’t handle today’s product complexity. Product complexity is more than just product architecture, requirements, and functions. Products are becoming more integrated into our lives, meaning companies need to be more concerned with risk and liability considerations. So, it makes sense that a recent study indicated that the primary expectation for the digital transformation investment is to improve the product development process. At the center of the Digital Engineering process is the product model, built upon relationships that take into account functions, requirements, architecture, risks, etc. The model also contains verification events and requirements to ensure implementation consistency. Used properly, a product model is a powerful tool.

Moving to a model-based engineering process

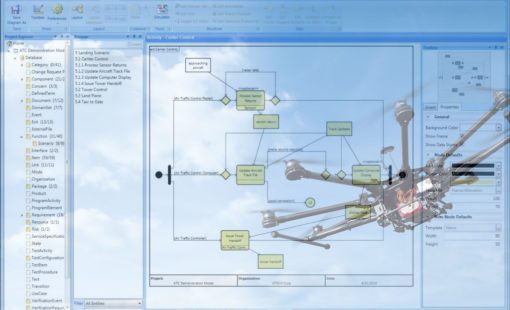

Moving to a model-based process seems much more challenging than initially thought. INCOSE introduced the Model-Based Systems Engineering (MBSE) initiative in 2007, but the term dates back to 1993. Clearly, adoption in the commercial space has been slow. I may be able to throw a little light on the problem of adoption after working through our own acquisition of a Systems Engineering company–Vitech Corporation. As an example, my background is hardware/software implementation–detailed design. And yes, it was all document-based. The Vitech acquisition gave me access to Systems Engineering industry leaders, their tools, and to Digital Engineering early adopters. As a detailed design engineer, I was trying to understand how the model-based engineering process would help make me more productive.

Houston, we have a problem

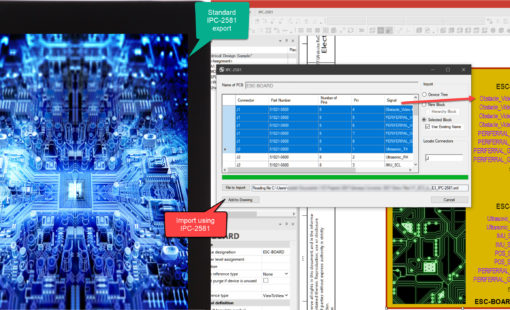

It became apparent that Systems Engineering and detailed design were disconnected. Even companies that have already adopted MBSE for product model development had difficulty making the connection to detailed design. Those early adopters converted the product model to documents for the detailed design teams. Consider building a vehicle with 100 electronic control units (ECUs). Each ECU development team needed a set of documents. Converting the model to documents could take weeks or months. Not only was the process painfully slow, but converting a relationship-based product description to a set of documents compromised the value of the model. Once the engineering team converts the model to documents, the model becomes disconnected from the product life cycle. Unfortunately, the rigorous product definition residing in the model gets left behind.

The model-based process gap

Digital engineering and model-based engineering processes have an extensive process gap. As companies discover this problem, they begin to tap the brakes on adoption. Can you blame them?

Ultimately, the solution is to connect the product model to detailed design. This means exposing the product model to the detailed design team in a manner that preserves the fidelity of the model while making it a part of the detailed design process. Look for part 2 of this post, discussing a first-generation solution to connect the model to detailed design.

Related Products & Resources

- White Paper

This eBook describes an MBSE based process for Electrical and Electronic design. The eBook begins with model content and structure with the purpose of implementation and the need for a “design envelope”.

- Products

Digital Engineering requires a model-based design process that begins in Systems Engineering. Zuken acquired Vitech Corporation, a leader in Systems Engineering practices and MBSE solutions, with the intent of implementing an E/E model-based design process.

- Products

Digital Engineering requires a model-based design process that begins in Systems Engineering. Zuken acquired Vitech Corporation, a leader in Systems Engineering practices and MBSE solutions, with the intent of implementing an E/E model-based design process.

- Solutions

Many companies have recently embarked on the “digital transformation” journey to become more efficient and competitive. A recent IDC study showed that 90% of small and medium-size businesses are budgeting for the digital transformation and 73% have begun the process. According to the survey, the top goal for these companies making the digital transformation journey is to improve product development and design processes.