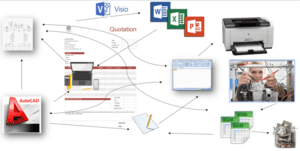

For most design-to-manufacturing companies, it can take multiple organizations to sell and deliver products. We can imagine these different organizations as islands. Traditionally, in isolation, these islands rely upon manual methods of communication. Which often requires data recreation or reentry.

Companies are searching for ways to automate the bridges between the business, design, and manufacturing islands. We will explore some of the design-to-manufacturing automation solutions that Harness Builder for E3.series provides to aid this quest.

Automating the Quotation

Having accurate initial quotations is vital to many manufacturing companies. If this initial quotation is inaccurate, there is a chance to lose the sales opportunity if the cost estimate is too expensive. On the other hand, if the estimate is too low, it could cause the company to produce the harness at a loss. Thus, it is essential to consider the turn-around speed and accuracy of the quotation.

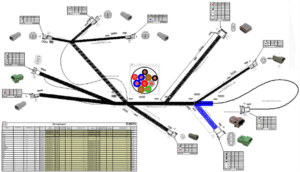

With Harness Builder for E3.series, it is possible to build a multi-purpose process to produce the quotation. This process involves creating a wiring harness design with ample detail and accuracy for a cost estimate. The estimate can then be the starting point for the final harness design. With a to/from list Excel spreadsheet, you can use the import feature to load this information into an E3.series project. Next, import and overlay the harness assembly design using Harness Builder for E3.series parts-ready database. By using this database, dependent part associations and additional parts are included automatically in the design. Using Zuken’s harness flattening process, you can automate this step using the wiring harness design based on 3D MCAD data. From there, generate a materials list where the conductor lengths and quantities are automatically calculated and included. Finally, use the Cost Estimator to provide the labor, material costs, and lead times calculations.

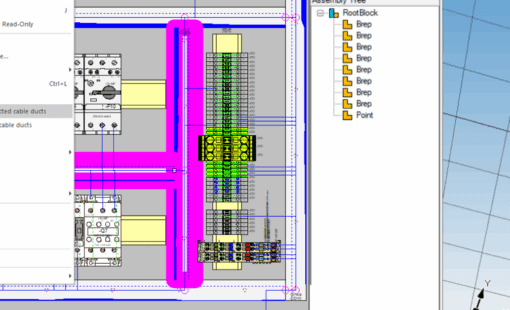

The Detailed Design Automation

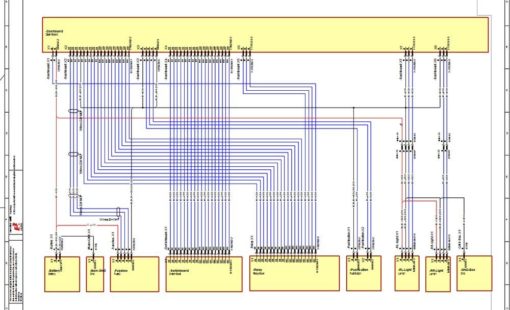

Once you are at the point of moving to detailed product design, you can continue to build off of the project. Harness Builder for E3.series offers even more automation features to speed up and accurately detail the harness assembly design. Some of these features include but are not limited to:

- Automatically calculate and place the cable protection based on the design.

- Creation of on-sheet BOM and wiring list reports.

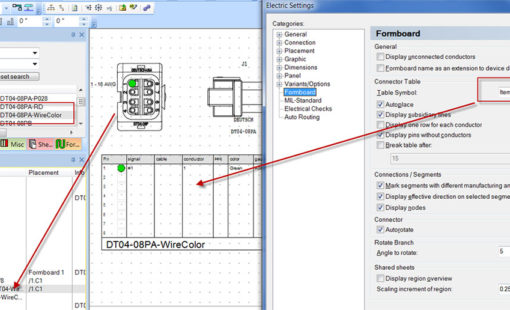

- Automatically generate helpful documentation of splice information and wire colors.

- The overall wire harness weight.

- Label exports directly to industry-leading labeling machines.

- Create work instructions directly from the original design in either printed form or displayed on a handheld tablet.

- Upload BOMs and revision-specific wiring information to the CETEC ERP system. Store the revision classification of the designs and builds in the cloud for easy access throughout the company.

Processing and Manufacturing

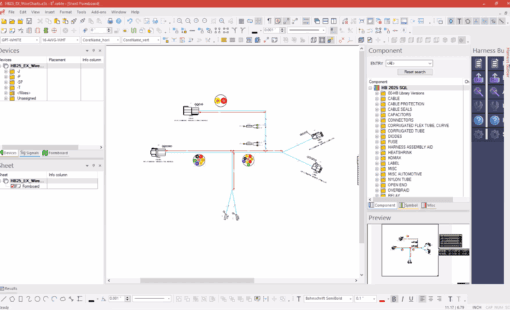

As a step towards automating the process of building and assembling wire harnesses, many companies are moving away from the old-fashioned harness boards and paper process–and introducing an augmented reality solution. Harness Builder for E3.series outputs a new electronic formboard file (EFB). Industry-leading solutions such as HarnessWorks and Laselec consume the EFB file and convert the data into step-by-step mixed reality work instructions projected or highlighted directly onto the harness board.

Another island to bridge is from the design to wire processing machines and wire harness test machines. Harness Builder for E3.series exports machine-readable formats, eliminating the need to program machines manually. Having these bridges helps to remove errors and effort often associated with manual program creation. Harness Builder for E3.series supports multiple machine manufacturers. In some cases, numerous machine formats for a given manufacturer. The cut, mark, and strip machine manufacturers include Komax, Schleuniger, Artos, Spectrum Technologies, Laselec Modena, Z and F / Weidmuller, and Laserwire. The software also supports DIT-MCO, CAMI Research, Nexeya, Cirris, Cablescan, C.K. Technologies, and Dynalab test machines. We are consistently adding new machine bridges with each software release.

Summary

Harness Builder for E3.series provides a flexible workflow and robust capabilities to bridge islands of processes from quotation to final build. We learned how Harness Builder for E3.series can help automate the initial cost estimation, detailed product design process, and programming required for manufacturing processes. Check out the full article in Wiring Harness News to learn more about how Harness Builder for E3.series contributes to charting a course for design-to-manufacturing automation. You can also visit the Zuken team EWPTE and receive a demonstration of this technology.

Related Products and Resources

- Products

- Products

- Products

E3.series is a Windows-based, scalable, easy-to-learn system for the design of wiring and control systems, hydraulics and pneumatics. The out-of-the-box solution includes schematic (for circuit and fluid diagrams), cable (for advanced electrical and fluid design), panel (for cabinet and panel layout), and formboard (for 1:1 wiring harness manufacturing drawings). Integrated with MCAD, E3.series is a complete design engineering solution from concept through physical realization and manufacturing output.