The introduction of ECAD in the 1980s was a big thing . . . I can vividly recall the DEC PDP 11’s and dedicated air-conditioned rooms.

While the A in ECAD has always stood for Aided, the level of support provided to engineering organizations has increased dramatically during recent years. With more than 30 years of industry experience, Craig Brown, Zuken Business Manager UK & Scandinavia, recounts how he has seen ECAD systems evolve from rudimentary electronic drawing boards through to today’s powerful collaborative engineering solutions.

Where it all started

I began my career as an apprentice in the late 1970s, so I am of an age where I remember designing PCBs without the aid of software. Schematics and layouts were just drawings. The introduction of ECAD in the 1980s was a big thing, as was the computer needed to run the software, I can vividly recall the DEC PDP 11’s and dedicated air-conditioned rooms.

From computer-based to computer-aided

Though wowed at the time as a computer-based solution for circuit and PCB design, the level of ‘aid’ was minimal. It mainly meant I didn’t have to draw things by hand, and it was only as we pushed into the 1990s that the systems came of age and exhibited useful intelligence. By the mid-2000s, I was no longer doing hands-on engineering, and I saw clearly how ECAD systems were beginning to support concurrent engineering and allowing hardware and mechanical engineers to work more collaboratively and, by extension, productively.

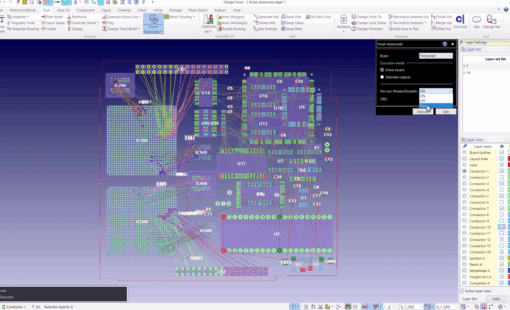

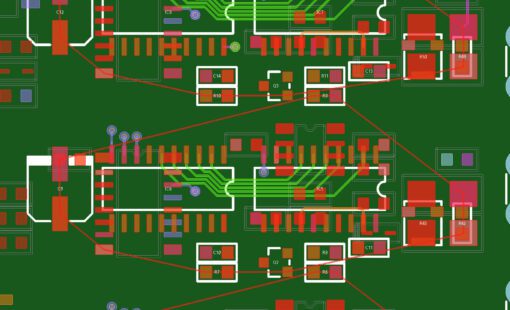

Understandably, during my ‘engineering years’ (about 20 in total), board complexity changed dramatically, from predominantly analogue with a small amount of mixed-signal, implemented using PTH technology, to high-speed digital implemented predominantly as SMDs. Thankfully, ECAD systems kept pace with the challenges associated with the technological advancements; e.g. catering for large BGA devices, board layers increasing, the need for blind, buried and micro vias, SI, EMC, thermal management, etc.

Pushing the limits

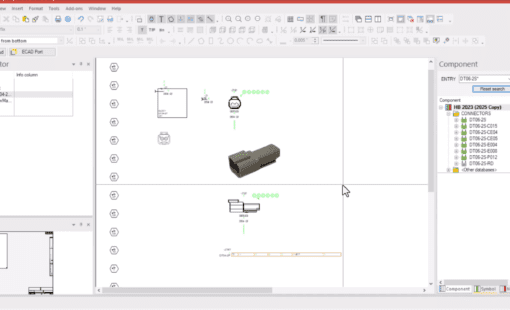

Today’s ECAD systems are extremely powerful and encompass both electrical and electronic design, plus have increased integration with MCAD systems. Moreover, the level of collaboration has grown to include other stakeholders; namely software engineers, test/safety/certification engineers, manufacture, field servicing, purchasing departments and so on. Indeed, it’s fair to say that the majority of process-driven, product development businesses, using Zuken’s electronic and/or electrical design solutions, are benefitting from our Product Data Management (PDM) solutions as well.

Also, because PDM drives a requirement to integrate with a company’s Engineering Resource Planning (ERP) and Product Lifecycle Management (PLM) environments, we’re engaging with our customers’ IT departments more than ever. Granted, we’re still developing ECAD solutions as discipline-specific ‘design authoring’ tools but, hey, our competitors are doing that too.

How we differentiate ourselves is that we actively strive to be an ‘engineering process partner’ rather than purely an ECAD vendor, and we seek to align ourselves with our customers’ visions of where they want to go. This vision alignment is aiding (there’s the A-word again) our shared journeys into an increasingly ‘connected’ and ‘smart’ world, in which advances in Model-Based Systems Engineering (MBSE) is also playing a key role.