Renewable energy systems, including solar, wind, and bioenergy, are essential for achieving sustainable energy goals and reducing the world’s dependence on fossil fuels. There are, however, significant technical challenges to designing these systems: these systems must be efficient, reliable, and seamlessly integrated with modern smart grid technologies. This involves managing high power densities, maintaining signal integrity, and adhering to strict safety standards.

To address these challenges, tools like Zuken’s CR-8000 and E3.series provide comprehensive solutions for PCB design, wire harness design, and control panel layout. These advanced software platforms enable engineers to optimize designs for renewable energy applications through enhanced system performance.

Key Challenges in Renewable Energy System Design

The design of renewable energy systems faces several critical challenges that engineers must overcome to create efficient solutions:

- Managing High Power Densities: Large amounts of energy must be controlled and distributed efficiently in applications like solar inverters and wind turbine converters. This can lead to issues: high power density designs increase thermal output, which affects the reliability and lifespan of electronic components.

- Maintaining Signal Integrity: Renewable energy systems often use complex signal processing and communication with smart grid networks, where clean signal transmission is crucial. Engineers must consider trace impedance, electromagnetic interference (EMI), and grounding to prevent signal degradation.

- Ensuring Compliance with Safety Standards: Engineers must ensure components and systems comply with international standards regarding electrical safety, environmental impact, and operational efficiency. This includes designing for fault tolerance, managing electromagnetic compatibility (EMC), and ensuring robust mechanical design to withstand potentially harsh environmental conditions.

- Optimizing Cable and Wire Harness Design: Effective wire harnessing accomplishes three things: it minimizes electrical losses, prevents mechanical failures, and ensures easy installation and maintenance. Detecting errors early in the design process can significantly reduce costs and improve system reliability.

Engineers can develop more efficient and sustainable renewable energy systems by understanding and addressing these challenges. Tools like Zuken’s CR-8000 and E3.series provide the necessary capabilities to tackle these issues head-on and foster innovation in the renewable energy sector.

How Zuken’s CR-8000 Addresses PCB Design Challenges in Renewable Energy Systems

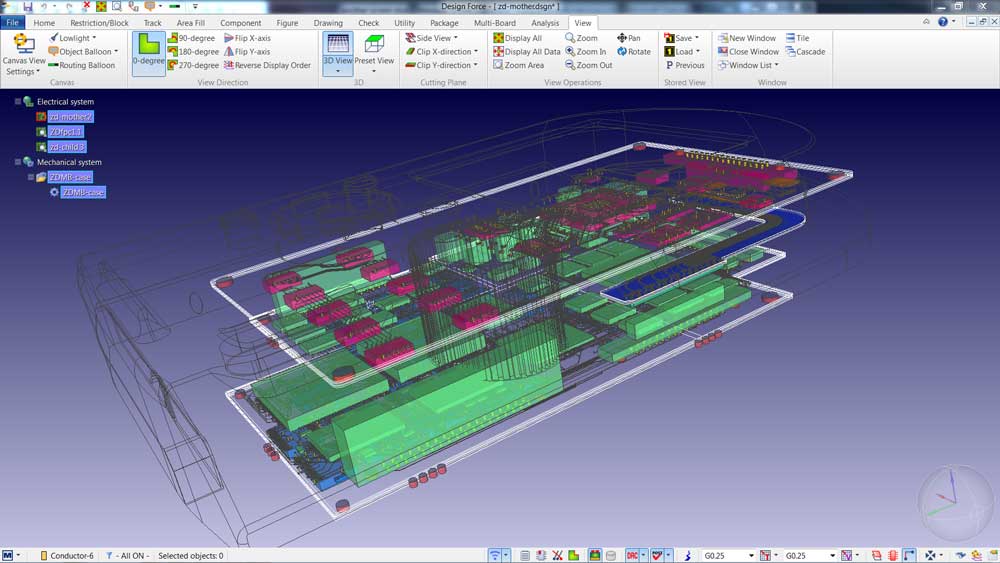

Zuken’s CR-8000 is a comprehensive PCB design platform with advanced capabilities tailored to the complex requirements of renewable energy systems.

- Advanced PCB Design Features: The CR-8000 platform supports multi-board systems making it possible for engineers to design complex power management and control electronics across interconnected PCBs. This capability is vital for cutting-edge renewable energy systems requiring modular and scalable designs that can handle varying power loads and conditions. The platform’s architecture design tools facilitate optimal component placement and routing, ensuring efficient energy distribution and minimizing power losses.

- Signal Integrity and Power Analysis: Zuken’s CR-8000 offers robust signal integrity (SI) and power integrity (PI) analysis tools. These tools enable engineers to model and simulate, under real world conditions, the electrical behavior of designs. Identifying potential signal integrity issues, such as crosstalk and EMI, early in the design process allows engineers to make adjustments preventing signal attenuation, which is critical in high-frequency renewable energy applications.

- Integration with Mechanical CAD (MCAD): The integration of CR-8000 with mechanical CAD (MCAD) software supports the seamless collaboration between electrical and mechanical design teams. This integration also ensures PCB designs are electrically sound and mechanically robust to survive in harsh operating environments.

- Compliance and Data Management: CR-8000 also includes integrated data management tools which help engineers maintain control over design revisions, configurations, and release processes. This feature is essential for achieving compliance with both national and international standards. Such features also ensure that all changes are tracked and documented, which in turn reduces the risk of non-compliance while enhancing overall design quality.

Zuken’s CR-8000 enables engineers to overcome the unique challenges of PCB design in renewable energy systems, leading to more reliable, efficient, and sustainable solutions. Zuken ensures that users can access various resources for CR-8000, including webinars, case studies, informative blog posts, and more. To add to the support provided, even special training can be scheduled. Adopters of this software can rely on Zuken to provide the assistance and insight needed to get the most out of their products.

The Role of E3.series in Wire Harness and Control Panel Design for Renewable Energy Systems

Zuken’s E3.series is a suite of tools for electrical wiring, cable, and harness design. Here is what E3.series has to offer engineers working in renewable energy systems:

- Wire Harness Design Capabilities:E3.series provides highly advanced wire harness design capabilities that enable engineers to create detailed, accurate designs for even the most complex electrical systems. It includes tools for automatically determining wire lengths, optimizing routing paths, and calculating the outer diameter of harness segments using intelligent packing algorithms. Such features can reduce material waste while ensuring the final designs are optimized for both performance and manufacturability.

- Digital Formboard and Design Validation: The digital formboard allows engineers to create a virtual prototype of the wire harness, which includes automatically calculating wire lengths and supporting the placement of connectors, terminals, and other components. Thorough design validation before physical production made possible through this feature helps prevent costly errors and reduces time to market.

- Interactive Automation and Design Rules: The E3.series incorporates interactive automation features to assist with tasks such as sizing, placement, dimensioning, and routing of harness branches and components. The built-in design rule check engine can continuously monitor the design against predefined rules. This ensures compliance with industry standards and improves overall design accuracy.

- Control Panel Layout and Visualization: Beyond wire harness design, E3.series provides integrated tools for control panel layout, routing and visualization. Engineers can design and visualize control panels in both 2D and 3D, ensuring that all components fit properly and function as intended with direct links to the underlying schematic. This is particularly beneficial for renewable energy systems with space constraints and heat dissipation needs.

- Integration with Other Design Software: E3.series integrates seamlessly with tools like Excel and mechanical CAD software to streamline workflows from design to manufacturing. With the added benefit of E3.3DTransformer, engineers can easily convert 2D wiring designs into 3D models, enabling better visualization and validation of wire harnesses within mechanical assemblies. This 3D integration helps detect space constraints and routing issues early, ensuring that designs are accurate and optimized before production.

- Manufacturing: E3.series enhances both manufacturing and assembly by capturing design intent and constraints early. It connects with leading automation platforms and integrates inspection tools for real-time validation. Through digital twin technology, it creates a virtual model for simulations and predictive maintenance, while the E3.ConnectivityBrowser ensures seamless access to design data from production through service and maintenance.

By leveraging the capabilities of E3.series, engineers can streamline the design and manufacturing of wire harnesses and control panels, reducing errors, ensuring compliance, and enhancing overall system performance. There are a wide variety of resources for E3.series. Zuken provides free, cloud-based Test Drive for E3.series, including four hours of tutorials to get you started immediately.

Integrating Zuken Tools for Optimized Renewable Energy Systems and Smart Grid Integration

Integrating Zuken’s CR-8000 and E3.series provides a comprehensive solution for designing and optimizing renewable energy systems.

Comprehensive Design Environment: By integrating CR-8000 and E3.series, engineers can work within a unified design environment. This environment facilitates collaboration across different domains and makes possible the seamless data exchange between PCB and wire harness design to ensure all components work together without design conflicts or errors.

Enhanced Error Detection and Correction: The combined capabilities of CR-8000 and E3.series enhance error detection and correction. CR-8000’s signal integrity analysis can identify potential EMI issues that might affect nearby EMI susceptible signals, while E3.series’ design rule checks can alert engineers to cable routing or component placement violations. Such a proactive approach can reduce the risk of costly redesigns and ensure high-quality renewable energy systems.

Support for Smart Grid Integration: As more renewable energy systems are connecting to smart grids, advanced design tools supporting communication and control technologies become critical. CR-8000 supports the design of PCBs that handle complex signal processing and communication tasks, while E3.series provides the necessary infrastructure for efficient power distribution and control panel design. These tools enable engineers to develop systems fully compatible with smart grid technologies.

Streamlined Workflow from Design to Manufacturing: Integration of CR-8000 and E3.series streamlines the design to manufacturing workflow. Tools for digital prototyping, design validation, and automated documentation make it possible for engineers to move quickly from the initial concept to the final product with fewer iterations. This streamlined process is definitely advantageous in the fast-evolving renewable energy sector, where time-to-market is critical.

Optimizing System Performance and Sustainability: The combined use of the CR-8000 and E3.series platforms support system performance optimization and sustainability. Detailed analysis and power distribution, signal integrity, and component placement help to ensure renewable energy systems are efficient, environmentally friendly, and sustainable.

Next Steps and Resources

To fully leverage the capabilities of Zuken’s CR-8000 and E3.series for renewable energy projects, explore these additional resources:

-

Webinars and On-Demand Sessions: Zuken offers webinars on essential topics in PCB design, wire harness design, and renewable energy integration, such as:

- “Wire Harness Design Automation Basics”: This webinar introduces the fundamentals of wire harness design automation, a critical component for engineers working on complex renewable energy projects.

- “AI-Based PCB Place and Route”: This session explores Zuken’s AI-based PCB design tool, enhancing the efficiency and precision of PCB layouts. Such precision is essential for renewable energy systems that must exhibit high performance and reliability.

- “Practical Signal Integrity for Improved EMI Control in PCB Design”: Learn about techniques for early detection of signal integrity, power integrity, and electromagnetic compatibility issues—vital for maintaining system reliability in renewable energy applications.

-

Further Reading on Hydrogen Energy:

- “HYVIA: Advancing Green Mobility with Hydrogen Technology”: This article provides insights into the potential of hydrogen fuel cell vehicles (FCVs) and the challenges associated with their adoption. It offers valuable context on the future of hydrogen technology and its integration with renewable energy systems.

- GreenGT’s Use of E3.series: GreenGT utilized E3.series to streamline the design and production of high-performance hydrogen fuel cell systems, significantly reducing development time and enhancing production efficiency. This case study illustrates the practical benefits of using Zuken’s tools and demonstrates how this type of advanced design software can accelerate innovation in the renewable energy sector.

Innovate with Advanced Software Solutions

For more information on how Zuken’s CR-8000 and E3.series can support your renewable energy projects and to access these valuable resources, visit Zuken’s website.