Optimizing Control Panel Designs for Improved Workflow and Efficiency

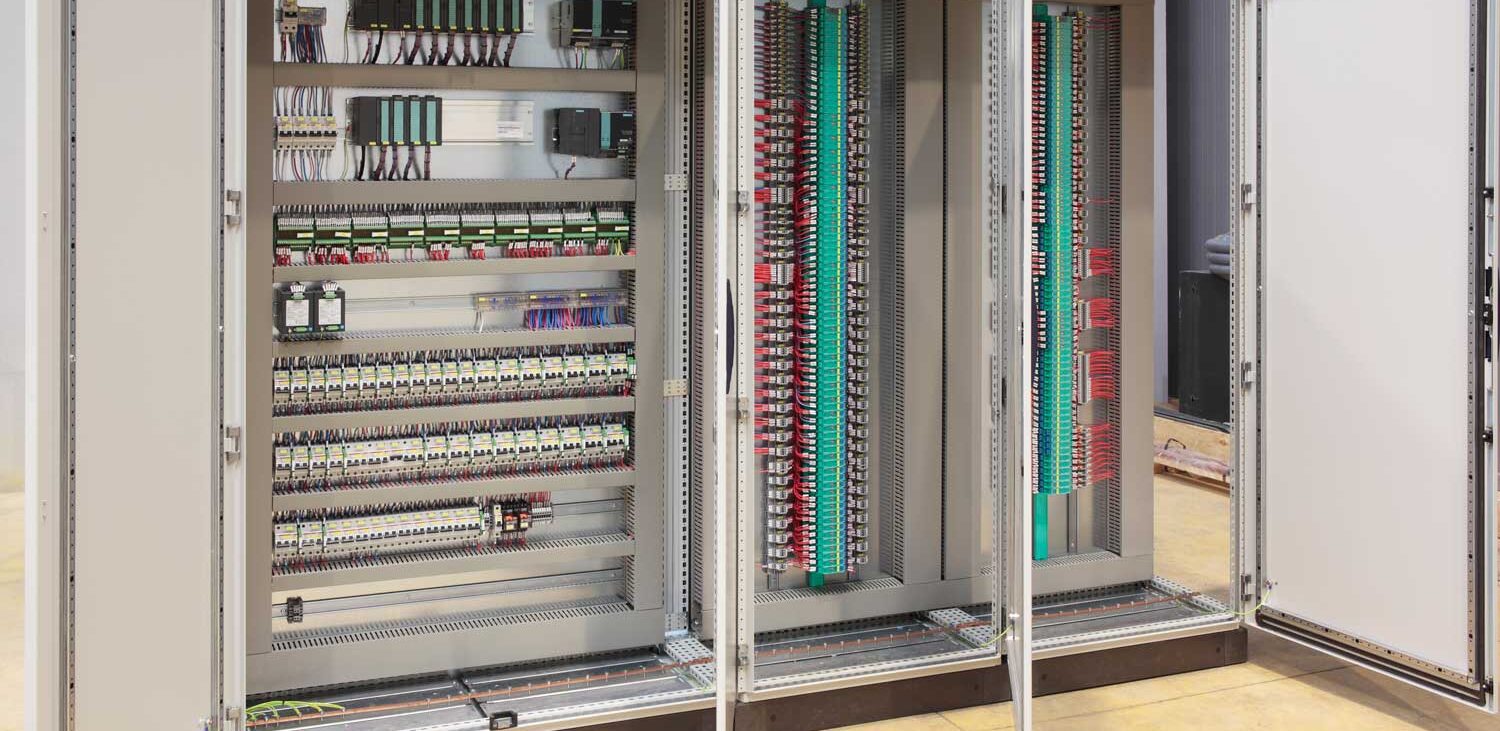

If you’re involved in the industrial automation and electrical design field, you know just how crucial a well-designed control panel can be. Not only does it help ensure the smooth operation of your equipment, but it can also help keep your workers safe and prevent costly downtime. This post will share the principles of effective control panel design and showcase how E3.series is essential in achieving optimal panel layouts.

The Importance of an Optimized Control Panel Layout

The control panel is the heart of every industrial automation system, housing the critical components that control machinery and processes. An optimized layout is more than fitting all necessary components within a physical space. It’s also about how these components interact with each other, the operators, and the environment in which they operate. A well-thought-out control panel layout can:

- Enhance Safety: Reducing the risk of accidents by ensuring clear labeling, proper component spacing, and adherence to industry standards.

- Improve Accessibility: Facilitating easy access to components for maintenance and troubleshooting reduces downtime.

- Boost Efficiency: Streamline the arrangement of components for better airflow and cooling and reduce the likelihood of malfunctions.

- Ensure Compliance: Meet regulatory standards and guidelines to avoid costly fines and redesigns.

Principles of Control Panel Design Optimization

When designing a control panel, several principles should guide the layout process to ensure optimization:

Modular Design

Modular design is an approach that involves dividing the control panel layout into sections or modules, each dedicated to a specific function. This approach simplifies manufacturing, assembly, and testing processes and allows for easier expansion or modification in the future. Therefore, designers can add new modules without a complete redesign. Modular design supports redundancy, improving system reliability by allowing individual modules to be replaced or serviced without affecting the entire system’s operation.

Ergonomics

Another essential principle is ergonomics, which focuses on designing control panels that are easy to use and interact with. These design considerations include placing controls and indicators within easy reach and view of the operator’s natural movements. Furthermore, ergonomic designs consider the component’s height, angle, and distance from the operator’s position. Proper ergonomic design reduces operator fatigue and errors, increases productivity, and improves safety by ensuring that emergency stops and critical controls are more accessible.

Thermal Management

Maintaining optimal operating temperatures within the control panel is essential, and effective thermal management is crucial in achieving this. Moreover, effective thermal management involves:

- Strategically placing components to ensure proper airflow.

- Using cooling systems (fans, air conditioners, or heat exchangers).

- Selecting materials that help dissipate heat.

Effective thermal management is essential to prevent component failure due to overheating, thereby ensuring the reliability and longevity of the system.

Space Efficiency

Optimizing space within the control panel is another important principle that involves efficiently arranging components and planning for future expansion and maintenance. Designers can enhance space efficiency by using compact components, planning cable routes intelligently, and adopting a layered or vertical component mounting approach. This principle ensures that the panel is not overcrowded, which could impede airflow or make maintenance difficult.

Standardization

Finally, standardization is essential for adhering to industry standards and best practices in control panel design, such as those specified by the International Electrotechnical Commission (IEC) or the National Electrical Manufacturers Association (NEMA). Additionally, standardizations facilitate easier compliance with international regulations and improve the marketability of the end product.

Zuken’s E3.series: A Catalyst for Optimization

E3.series is a comprehensive electrical design solution that addresses the challenges of control panel layout optimization head-on. With its robust set of tools designed specifically for electrical engineers, E3.series streamlines the design process from conceptualization to production. Here’s how it aids in optimizing control panel layouts:

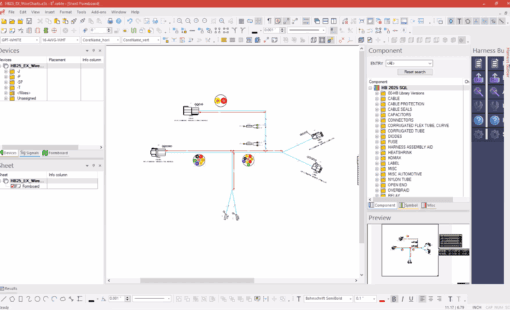

Intelligent Component Selection and Placement

E3.series facilitates intelligent component selection by providing an extensive components library with electrical characteristics and physical dimensions. Designers can easily select components that best fit their requirements. The software automatically checks for compatibility and constraints. These checks ensure optimal placement within the panel layout. It also reduces the risk of errors and rework. Ultimately, it saves time and resources. Furthermore, designers can confidently meet necessary thermal management requirements by using placement checks for components with higher heat dissipation.

Design Variants and Subcircuit Usage

There are a couple of ways in which E3.series can support modular designs of the control panel layouts. First, using options and variants in E3.series makes it easy to include different design configurations in a single project. As we all know, changing one project is more manageable than multiple projects. So, having the ability to create a 150% design reduces change implementation and lowers the risk of errors, as well as making it simple to develop expandable designs.

Second, designers can save and reuse module designs with E3.series through subcircuits. Users can create subcircuits with any part of a design to export as a file, copy internally to a project, or save to their parts database. They can then copy or incorporate as needed into their projects, loading in all design information like the logical connections and part placements. To prevent design issues and manual effort, E3.series will automatically rename any devices or wires to avoid duplicate naming. By utilizing subcircuits, designers can reduce the time spent creating redundant module designs.

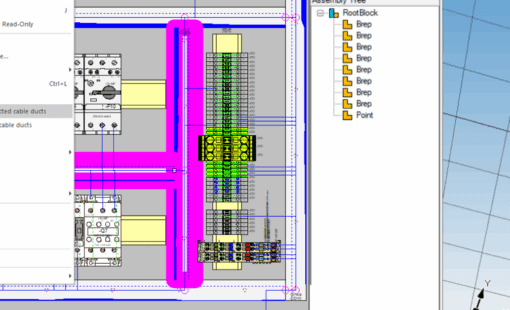

Automatic Wire Routing

The automatic wire routing feature of E3.series significantly enhances the efficiency of the design process. By automatically calculating the shortest and most efficient paths for wiring, the software reduces the length of wires needed, minimizes electromagnetic interference, and ensures a clean, organized layout. Additionally, E3.series helps prevent overstuffing cable ducts with built-in design checks and overfill prevention. These features speed up the design phase, reduce material costs, and simplify the assembly process.

Control Panel Design 3D Visualization

The 3D visualization capabilities of E3.series provide:

- A detailed view of the control panel from every angle.

- Allowing designers to identify potential issues such as interference.

- Improper component placement.

- Accessibility challenges before building the panel.

This immersive visualization aids in optimizing the layout for functionality and maintenance, ensuring that the final product is efficient and user-friendly. Moreover, the capability to design in a 2D representation of the 3D environment makes it simple for anyone who is not a 3D CAD expert.

Compliance and Documentation

Consequently, ensuring compliance with industry standards and generating comprehensive documentation become seamless with E3.series. It incorporates design rules such as device and wire naming and standard schematic symbols. It also generates all necessary documentation, including wiring diagrams, part lists, and assembly instructions, ensuring the panel meets regulatory requirements and simplifying the certification process.

Conclusion

Optimizing control panel layout is not just about making components fit within a confined space; it’s about creating a safe, efficient, and adaptable system. E3.series provides the tools and capabilities to achieve these objectives, transforming the control panel design process into a streamlined, error-free endeavor. By leveraging E3.series, designers can ensure their control panels are optimized for improved workflow and efficiency, enhancing overall system performance and reliability.

Related Products and Resources

- Products

- Products

E3.series is a Windows-based, scalable, easy-to-learn system for the design of wiring and control systems, hydraulics and pneumatics. The out-of-the-box solution includes schematic (for circuit and fluid diagrams), cable (for advanced electrical and fluid design), panel (for cabinet and panel layout), and formboard (for 1:1 wiring harness manufacturing drawings). Integrated with MCAD, E3.series is a complete design engineering solution from concept through physical realization and manufacturing output.