CR-8000 with SI/PI/EMI simulation and analysis and rapid prototyping slash Ontec’s project schedule

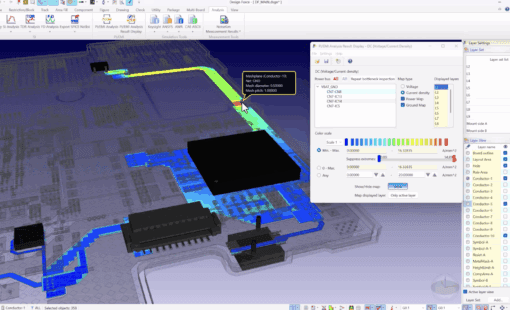

What do you do if your next project is high speed, with exceptionally stringent EMI requirements, and has to be complete in less time than you’ve ever developed a product before? When the Ontec team found themselves facing that predicament, they turned to Zuken. Why? Because Zuken’s CR-8000 PCB development platform has robust interfaces to popular simulation tools. That enabled Ontec to harness the strengths of CR-8000’s implementation capabilities while performing tightly integrated analysis with Keysight’s SI PCB simulation technologies (ADS, SIPro, and Momentum) and ultimately reduce the project’s overall analysis time by 86%.

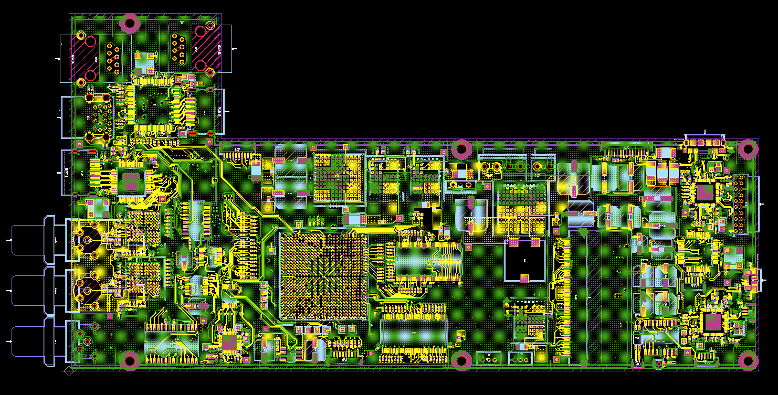

Ontec took on a project to develop a digital multi-media/multi-format transmission system for commercial broadcast television. This high-speed digital design also had highly restrictive EMI and noise requirements. The customer’s aggressive timeline meant that a re-spin would not be possible. It had to be “right the first time”. For Ontec, this required that they optimize their design process and reduced PCB simulation and analysis time.

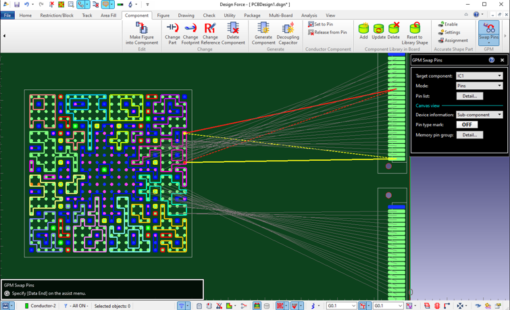

Ontec’s design methodology made effective use of simulation throughout the entire flow, starting from pre-layout. Analysis began at placement (pre-route) and was re-analyzed after routing using Keysight’s Momentum. CR-8000’s ability to intelligently reduce the volume of data transferred to ADS for simulation reduced overall analysis time and had a positive impact on the schedule. Using ABL (ADS Board Link) format, engineers were able to extract and transfer only the essential regions of the circuit required for simulations. Ontec was able to perform analysis early on, using the results to drive further design decisions.

Getting it right the FIRST time

To ensure right-the-first-time design, Ontec needed to calibrate its flow and corroborate the simulation results. CR-8000 proved to be invaluable for rapid prototyping. Ontec created several test boards early in the project. These test boards allowed for further measurements and adjustments, which ultimately reduced the number of prototype boards required. This approach exposed the excessive reflection at the connector, which was not a consideration in the PCB simulations. Rectifying these discrepancies enabled the simulation result to align with actual measurements. In turn, this established confidence in the flow and in the resulting product.

During the post-layout phase of the project, engineers moved the design to Keysight ADS. Therefore, they were able to perform improvement variations–what-if analysis–across the design and solution space. CR-8000’s ability to transfer ABL bi-directionally allowed design engineers to re-import verified design updates directly from ADS without the need for re-entering by hand. This functionality saved valuable time and minimized the potential for human error.

With the help of board design solutions from Zuken and SI PCB simulation solutions from Keysight, Ontec was able to identify and address performance-limiting issues early in the development process. They effectively mitigated the risks and ensured product quality within the compressed design cycle to reduce analysis time by 86%.

Read the full Success Story for all the details.

Related Products

- Products

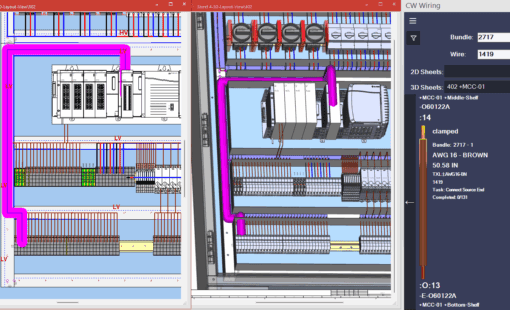

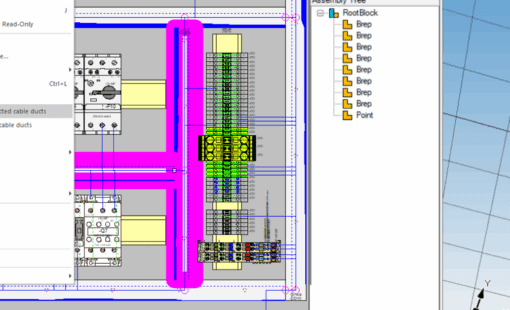

Zuken reveals details of release 2020 of its advanced 3D multi-board EDA environment CR-8000.

- Products

Building a competitive product today is much more difficult than a few years ago. Existing PCB-centric design processes are limited to a single PCB and do not provide the necessary tools for today’s competitive product development environment. PCB-centric design processes are falling behind.